Section 08 ENGINE MANAGEMENT (4-TEC)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

Connect one test probe to the WHITE/GREY wire

and the other test probe to the switch top termi-

nal. Measure resistance, it must be close to 0

ohm.

Connect one test probe to the BLACK wire and

the other test probe to the switch ring. Measure

resistance, it must be close to 0 ohm.

Safety Lanyard on Switch

Connect test probes to switch BLACK and

BLACK/YELLOW wires. Measure resistance,

it must be close to 0 ohm.

SPARK PLUGS

Disassembly

WARNING

Never remove ignition coil from the spark

plug without disconnecting it from the wiring

harness. Flammable vapors may be present

inthebilgeandignitedbyasparkwhich

could cause an explosion.

Disconnect the wiring harness from the ignition

coil.

Remove the ignition coil.

First unscrew the spark plug one turn.

Clean the spark plug and cylinder head with pres-

surize air then completely unscrew.

Spark Plug Installation

Prior to installation make sure that contact sur-

faces of the cylinder head and spark plug are free

of grime.

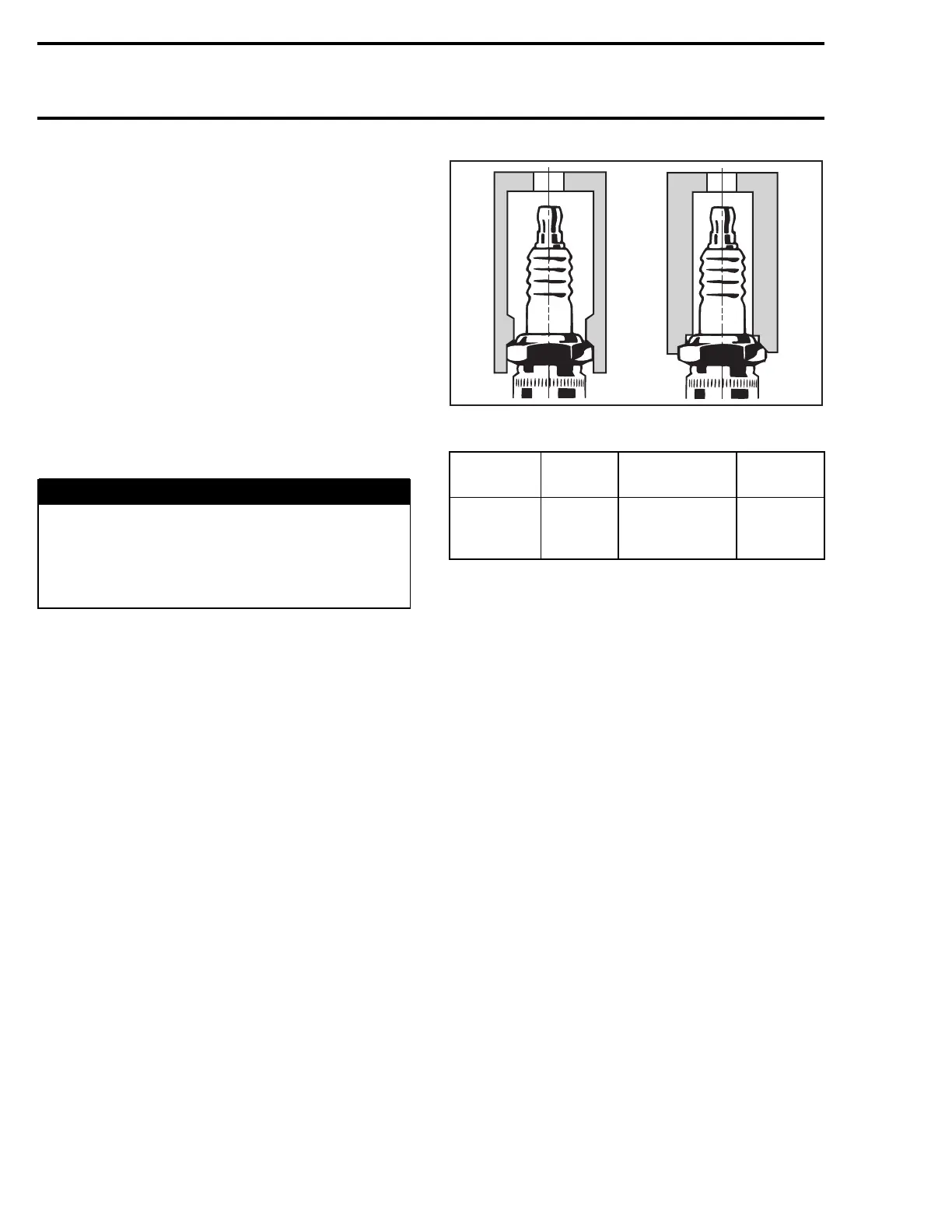

1) Using a wire feeler gauge, set electrode gap

according to the following chart.

2) Apply anti-seize lubricant over the spark plug

threads to prevent possible seizure.

3) Hand screw spark plug into cylinder head.

Then, tighten the spark plug clockwise an

additional 1/4 turn with a proper socket.

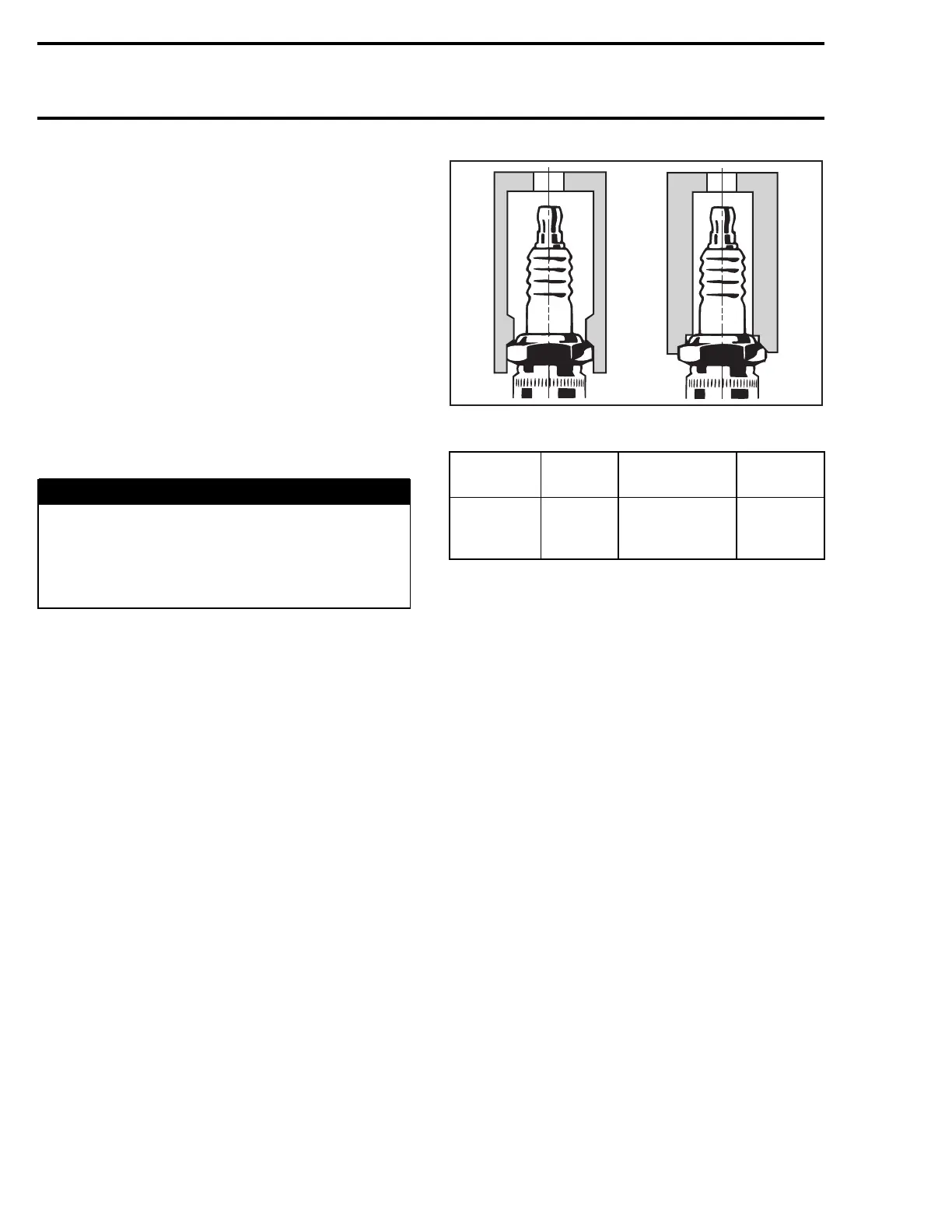

A00E0BA

2

1

1. Proper socket

2. Improper socket

ENGINE

SPARK

PLUG

TORQUE

GAP

MM (IN)

All 4-TEC

NGK

DCPR8E

Hand tighten

+ 1/4 turn with

asocket

0.75 (.030)

CRANKING SYSTEM

See above for start/stop switch and the DESS post

testing. Refer to STARTING SYSTEM section for

other tests.

438 smr2004-Complete Line Up

Loading...

Loading...