Section 07 ENGINE MANAGEMENT (DI)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

FUEL PUMP

Pressure Test

The pressure test will show the available pressure

from the fuel pump.

Ensure there is no leak from hoses and fittings.

Repair any leak.

Ensure there is enough gas in fuel tank.

UsetheVCK(VehicleCommunicationKit)tore-

lease the fuel pressure in the system. Look in the

Activation tab of the software B.U.D.S.

Disconnect inlet and outlet hoses from fuel pump

using tool (P/N 529 035 714).

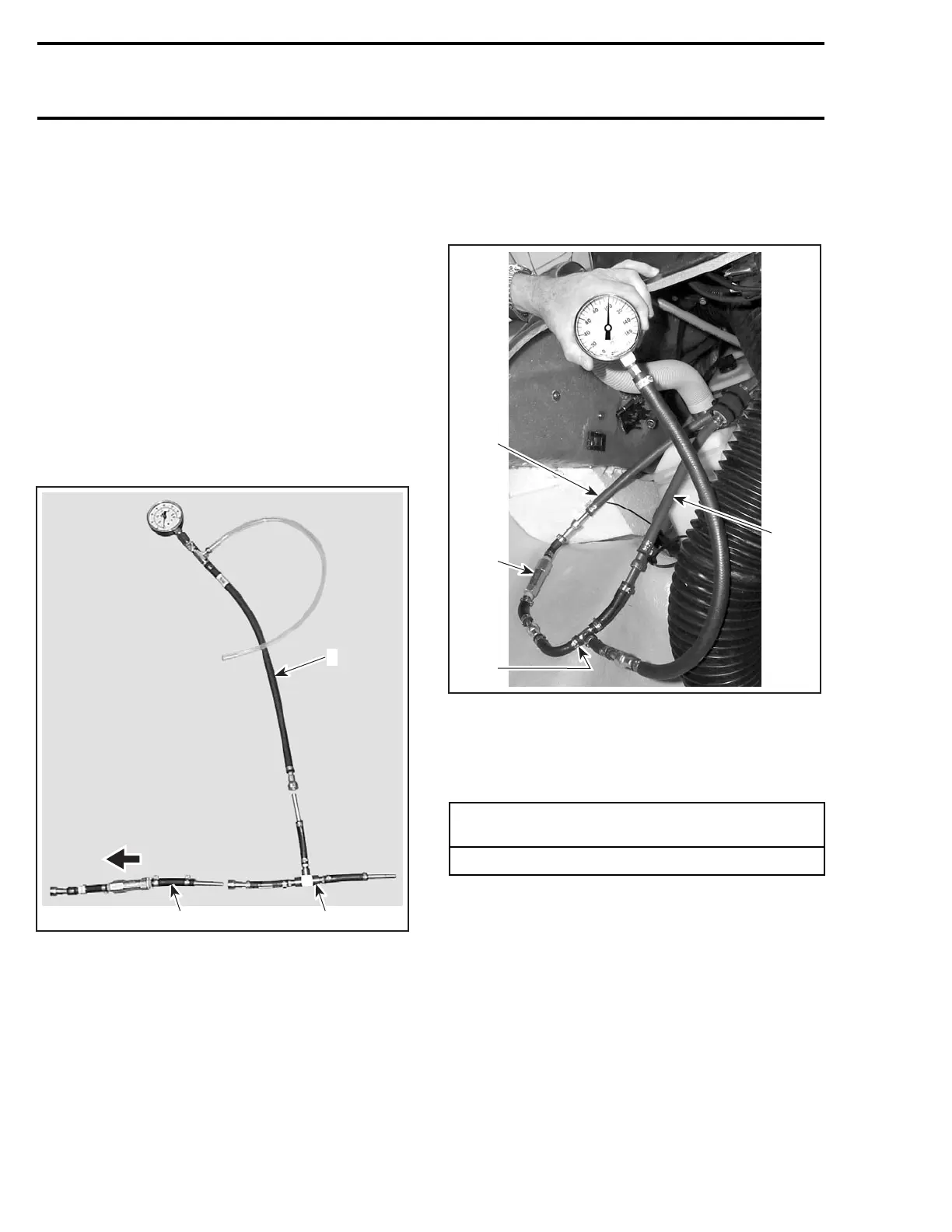

Connect T-adapter and pressure relief valve to

pressure gauge as shown.

32

1

F12R0AA

1. Pressure gauge (P/N 529 035 709)

2. T-adapter (P/N 529 035 710)

3. Pressure relief valve (P/N 529 035 711)

CAUTION: Make sure to install pressure relief

valve to allow excess pressure to escape and

to point valve arrow as shown above. Note the

arrow on the valve. Otherwise, air compressor

components might be damaged.

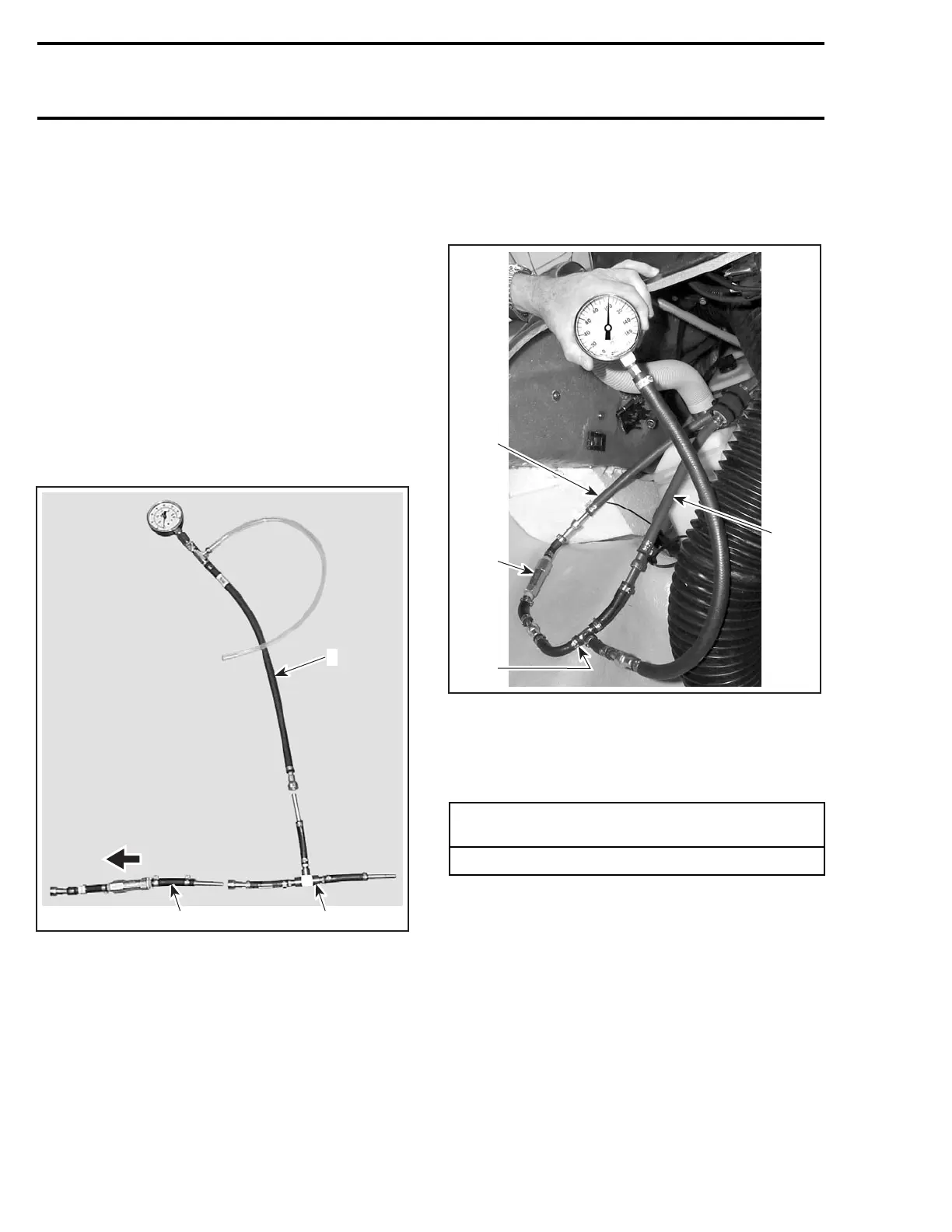

Install pressure gauge between disconnected

hoses on fuel pump side (closed-loop installation

on fuel pump). Make sure the pressure-relief

valve is installed on the fuel pump return line side.

1

2

3

4

F12R0BA

1. Fuel pump outlet hose (fuel filter side)

2. Fuel pump return line

3. Fuel relief valve on the return line side

4. Pressure gauge between disconnected hose (inline installation)

Install safety lanyard and observe fuel pressure.

MINIMUM FUEL PUMP PRESSURE

(when installing safety lanyard)

721 kPa (105 PSI)

If pressure is within limits, fuel pump is working

adequately.

If pressure is below limits, ensure fuel filters are

not obstructed. There is one in-line fuel filter at

the fuel pump outlet hose and one filter at the

inlet underneath the pump. Otherwise, replace

the fuel pump.

Remove pressure gauge and reinstall fuel hoses.

At installation apply engine oil on O-ring.

352 smr2004-Complete Line Up

Loading...

Loading...