Section 07 ENGINE MANAGEMENT (DI)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

Otherwise, check the resistance of the direct in-

jector circuit.

Reconnect the injector and disconnect the AMP

connector number 4 on the MPEM.

Using a multimeter, check resistance value be-

tween terminals as follows.

COMPONENT TERMINAL LOCATION

Direct injector MAG

5 and 15

Direct injector PTO

6 and 21

The resistance should be between 1 and 1.6 .

If resistance value is correct, try a new MPEM.

Refer to MPEM REPLACEMENT procedures else-

where in this section.

If resistance value is incorrect, repair the wiring

harness/connectors between AMP connector and

direct injector.

Direct Injector Replacement

IMPORTANT: Do not remove direct injectors

needlessly. They are sealed with a carbon dam

thatmayexpandwhenpulledout. Aspecialtool

is required to compress it prior to reinstalling.

Otherwise, sealing efficiency might be affected.

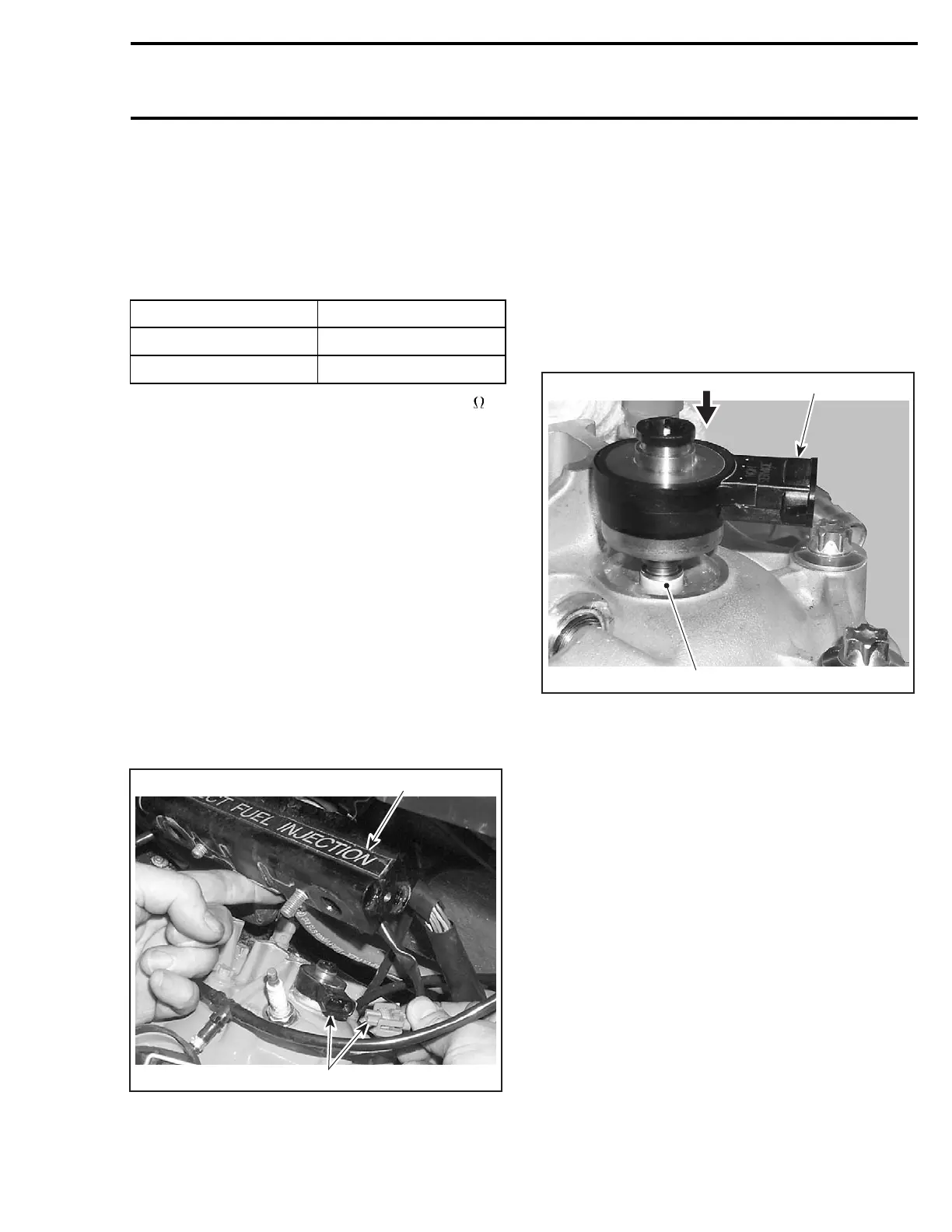

Remove air/fuel rail retaining screws. Partially lift

rail to allow direct injector removal.

Disconnect direct injector connector then pull in-

jector out of cylinder head.

1

F12R0GA

2

1. Air/

fuel rail

2. Disconnect and pull injector out

Compress the carbon dam using tool (P/N 529 035

716).

Carefully install direct injector in cylinder head

paying attention to carbon dam insertion. Ensure

to position connector pointing toward bottom of

cylinder head.

NOTE: A thin film of injection oil may be applied

to carbon dam if necessary to ease insertion in

cylinder head.

Reconnect electrical connector.

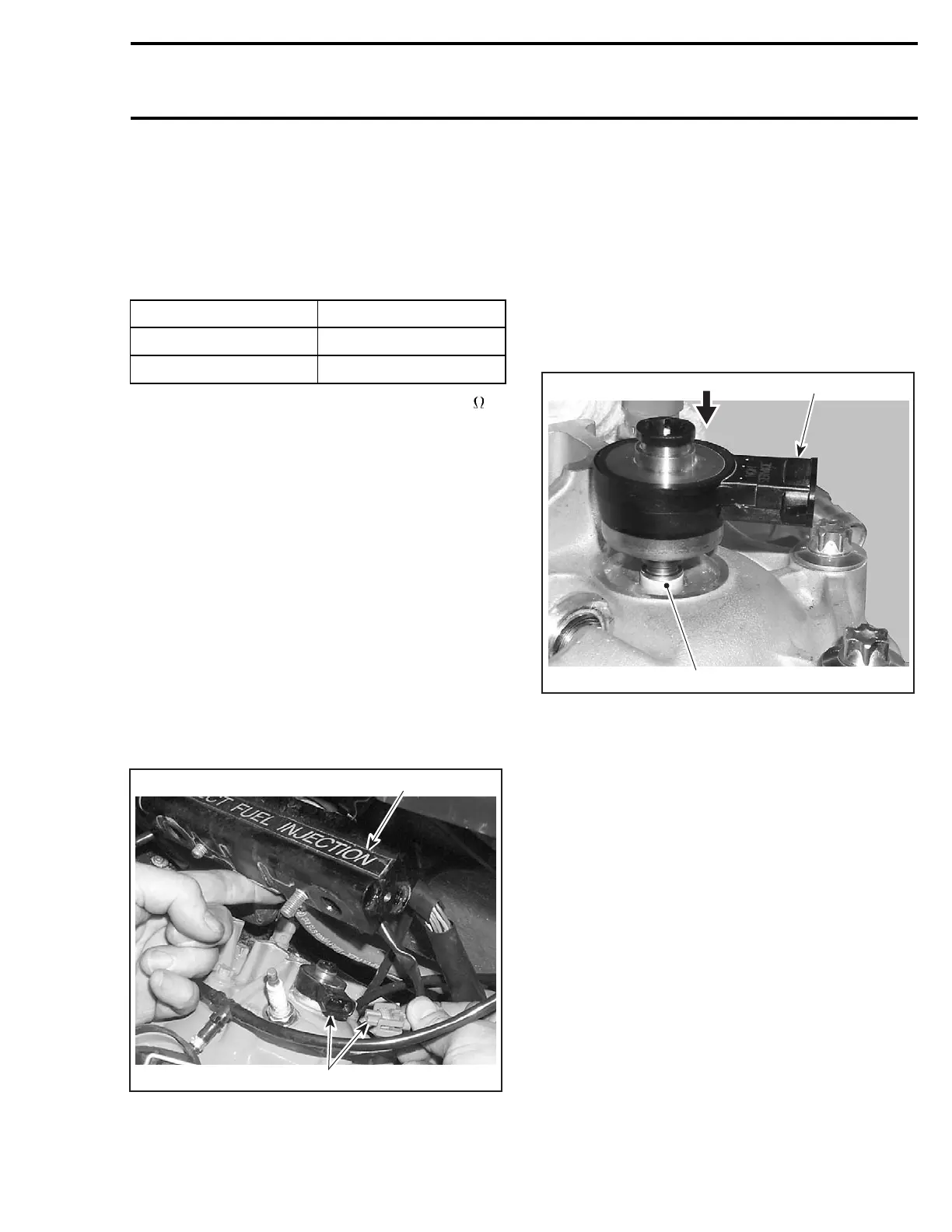

F12R0HA

1

2

1. Carefully insert direct injector

2. Connector pointing toward bottom of cylinder head

Reinstall air/fuel rail.

Carbon Dam Replacement

Remove direct injector. See procedure above.

NOTE: When replacing a carbon dam, it is rec-

ommended to replace it on both injectors. It is

also recommended to replace all O-rings. When

servicing air/fuel rail or direct injectors, we recom-

mend replacing carbon dams that have been run-

ning for 50 hours or more.

CAUTION: Never reuse a carbon dam after it

has been removed from the injector. Always

install a new one.

Remove carbon dam and O-ring using a small pick.

Install seal guide (P/N 529 035 715) on end of injec-

tor. Carefully slide carbon dam in injector groove.

Use carbon dam compressor (P/N 529 035 716) to

compress carbon dam evenly.

smr2004-Complete Line Up 351

Loading...

Loading...