Section 07 ENGINE MANAGEMENT (DI)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

ELECTRONIC MANAGEMENT

MPEM REPLACEMENT

General

NOTE: Prior to replacing a suspected MPEM, en-

sure that all the recommendations in the general

introduction of this section have been followed.

NOTE: When MPEM is replaced, the TPS closed

position and the ignition timing setting must be re-

set. Refer to their specific section for adjustment.

To allow transferring the previous recorded in-

formation from the old MPEM to the new one,

use the vehicle communication kit (VCK) with the

B.U.D.S. software. Use MPEM Replace in the

Module menu. Follows instructions in its help

system.

NOTE: If the old MPEM is working, it must be

read inside B.U.D.S. prior to removing it from the

vehicle to carry vehicle information and history to

the new MPEM. Besides, select the Setting tab

andnotetheOffset Angle in the Ignition box.

When installing the new MPEM, re-use this angle

as a preliminary setting. Then, proceed with the

regular procedure for the ignition timing setting.

If the old MPEM is not working, try to find a previ-

ous saved file from B.U.D.S. Otherwise, perform

the operations described in IF THE PREVIOUS

MPEM WAS NOT READ WITH B.U.D.S. below.

Replacement

Disconnect battery cables.

WARNING

Battery BLACK negative cable must always be

disconnected first and connected last.

Disconnect AMP connectors from MPEM.

Remove MPEM.

Install the new MPEM on the vehicle.

Reconnect AMP connectors to MPEM then bat-

tery cables.

If the previous MPEM was read with B.U.D.S.

Transfer the data from the previous MPEM to the

new one using B.U.D.S. then proceed with the

required resets after following the procedure in

VALIDATING TPS SYNCHRONIZATION below.

If the previous MPEM was NOT read

with B.U.D.S.

– Enter the vehicle and engine serial numbers in

the Vehicle tab.

– Enter the old MPEM serial number in the Part

Replacement under History tab. Click on Add

part in History.

– Reprogram safety lanyard(s).

NOTE: The MPEM serial number can be found on

the MPEM sticker that also shows the P/N.

Continue procedure as per VALIDATING TPS SYN-

CHRONIZATION below.

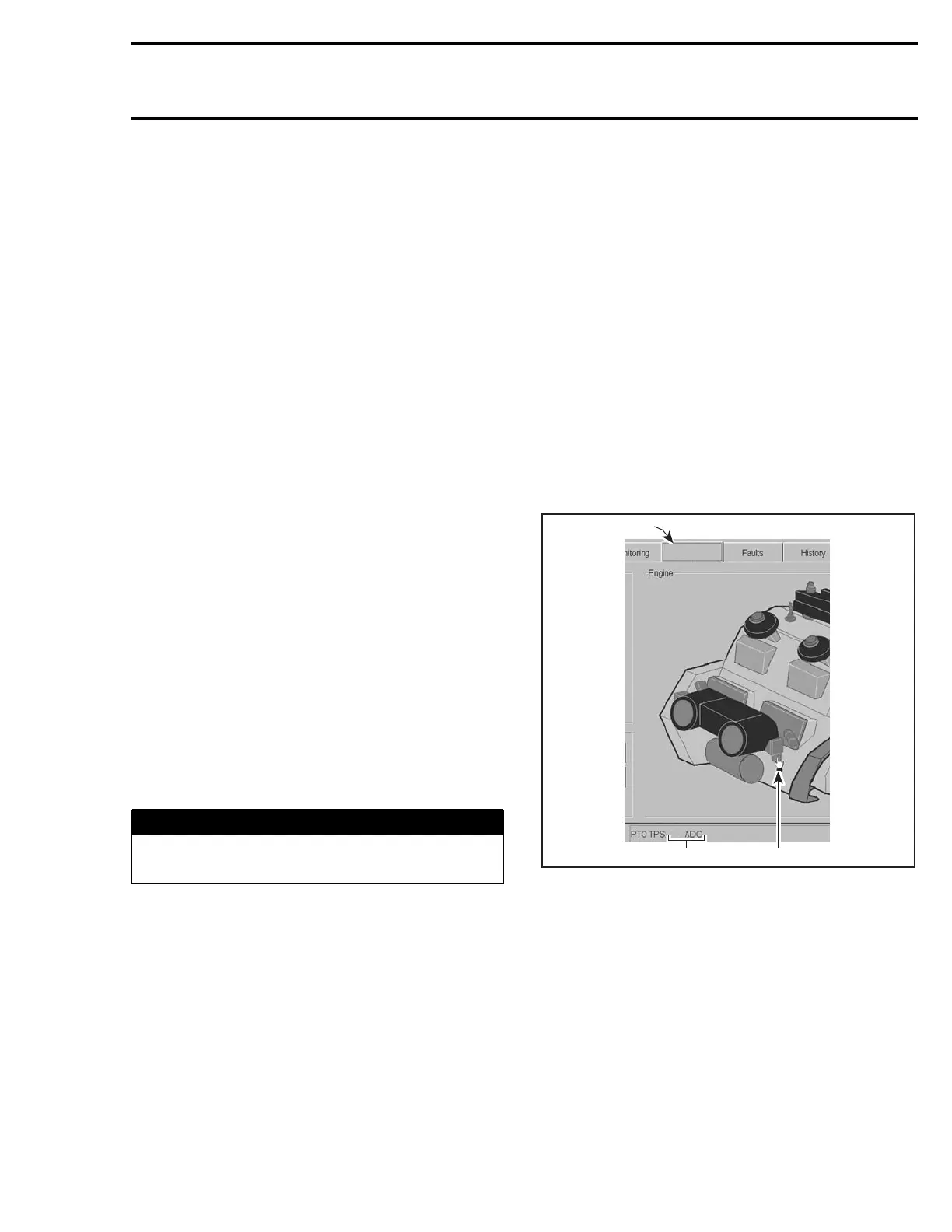

Validating TPS Synchronization

Select the Activation tab.

Point the mouse cursor over the PTO TPS. Check

the ADC reading. It must be between 23 and 45.

Activation

30

1

3

F12R1JA

2

1. “Activation” tab

2. Point on PTO TPS

3. ADC reading

PointthemousecursorovertheMAG TPS. Check

the ADC reading. It must be between 37 and 59.

If either readings are not within those parameters,

they are out of range and the MPEM will be unable

to initialize. Proceed with THROTTLE BODY SYN-

CHRONIZATION as detailed in THROTTLE BODY.

If the ADC's are within range, proceed with the

required resets.

smr2004-Complete Line Up 357

Loading...

Loading...