Section 06 ENGINE MANAGEMENT (RFI)

Subsection 03 (COMPONENT INSPECTION )

Also remember this validates the operation of the

sensor at ambient temperature. It does not val-

idate the over temperature functionality. To test

it, the sensor could be removed from the engine/

muffler and heated with a heat gun while it is still

connected to the harness to see if the MPEM will

detect the high temperature condition and gener-

ate a fault code.

When working with injectors, the resistance value

might test good while the complete current would

notflowthroughthewirewhenpulsatingcurrent

is supplied to the injector in its normal operation.

A solution would be to use a jumper wire to direct-

ly supply the injector from the MPEM. If it now

works, replace the defective wire. A Noid light

(available from after-market tool/equipment sup-

pliers) may also be used to validate the injector

operation.

AIR INDUCTION SYSTEM

THROTTLE BODY

Check that the throttle plate moves freely and

smoothly when depressing throttle lever.

FUEL DELIVERY

FUEL FILTER

To inspect the fuel filter, the fuel pump assembly

has to be removed from the fuel tank. See RE-

MOVAL in this subsection for the procedure.

FUEL PUMP

The fuel pump operation can be checked as fol-

lows.

Install the safety lanyard cap on the switch. The

fuel pump should run for approximately 1 second

and then shut off.

If not, check the electrical circuit and the 10 A fuse

on the MPEM module.

REGULATOR

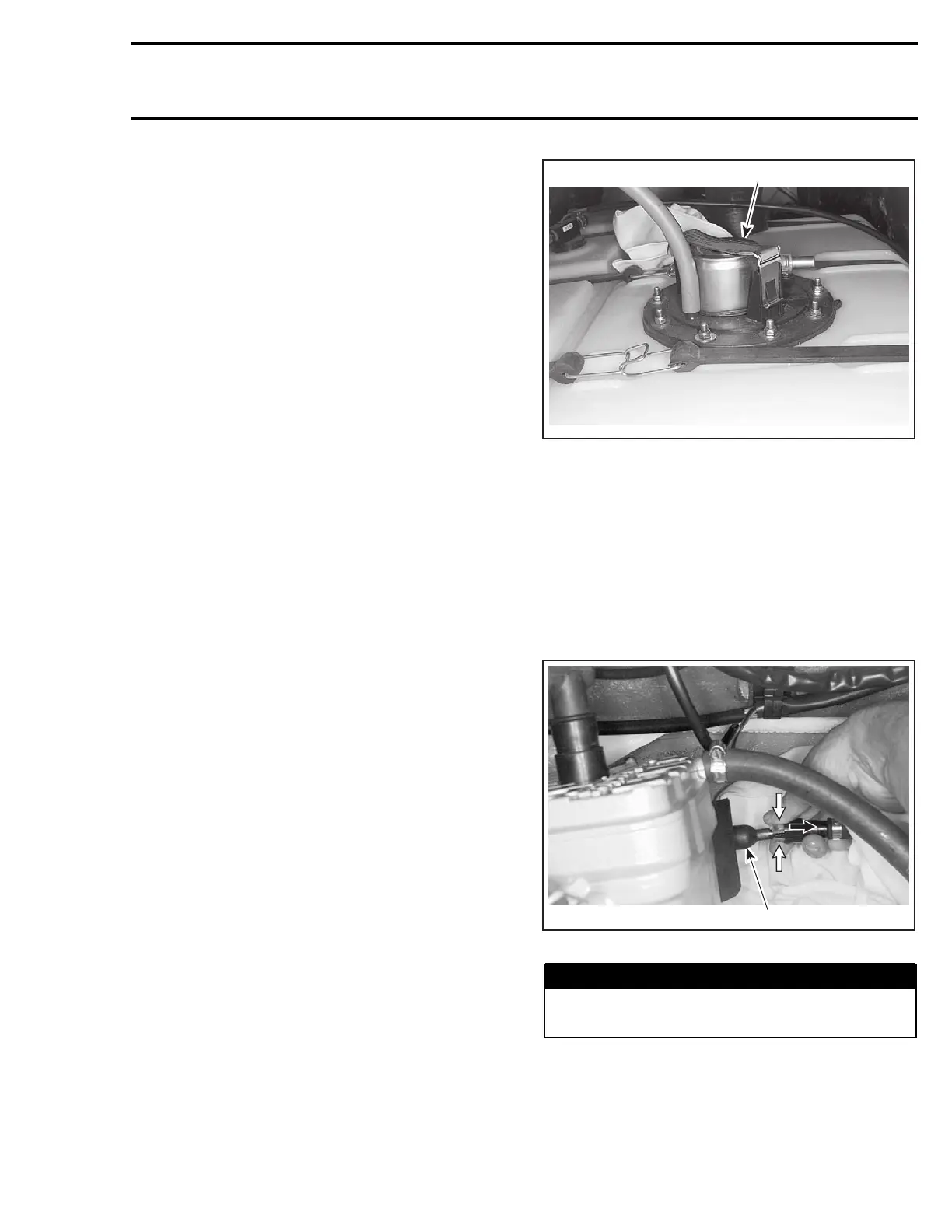

The regulator is mounted on top of the fuel pump

assembly.

1

F07F0DA

1. Regulator

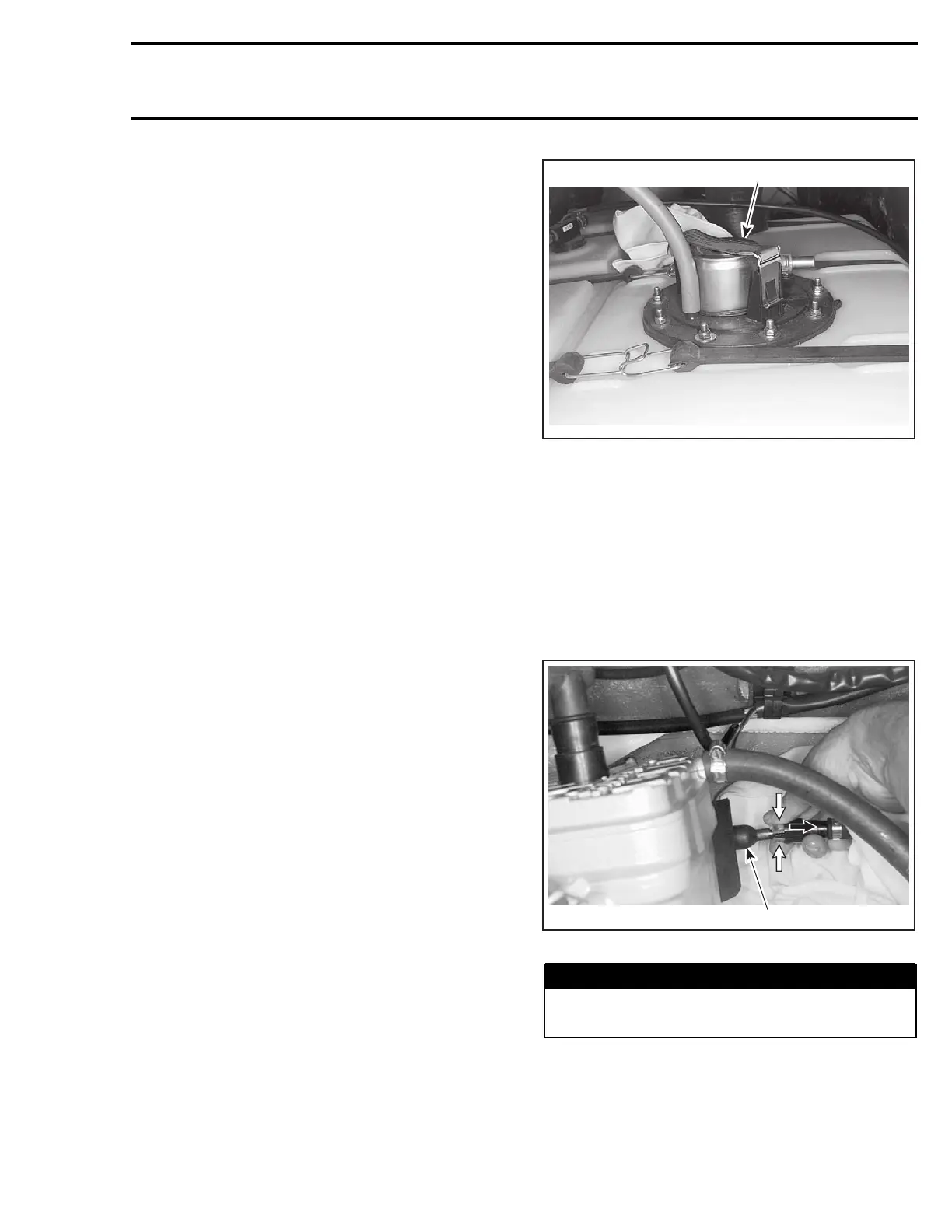

To inspect the regulator, a fuel pressure test must

be done.

Check that battery voltage is above 12 volts.

Place a suitable container below the quick connect

fitting of the fuel rail.

Cover the quick connect fitting with a shop towel.

Press on both tabs and disconnect the quick con-

nect fitting.

F07F11A

1

1. Fuel rail

WARNING

Fuel is under pressure. Wipe off any fuel

spillage in the bilge.

smr2004-Complete Line Up 309

Loading...

Loading...