Section 06 ENGINE MANAGEMENT (RFI)

Subsection 03 (COMPONENT INSPECTION )

WARNING

All electrical actuators (injectors, fuel pump,

RAVE solenoid, ignition coil and starter sole-

noid) are permanently connected to the bat-

tery positive terminal, even when the safety

lanyard is removed. Always disconnect the

battery prior to disconnecting any electric or

electronic parts.

To perform verifications, a good quality multimeter

such as Fluke 111 (P/N 529 035 868) should be

used.

Pay particular attention to ensure that pins are

not out of their connectors or out of shape. The

troubleshooting procedures cover problems not

resulting from one of these causes.

WARNING

Ensure all terminals are properly crimped on

wires and connector housings are properly

fastened.

Before replacing a MPEM, always check electri-

cal connections. Make sure that they are very

tight and they make good contact and that they

are corrosion- free. A “defective module” could

possibly be repaired simply by unplugging and

replugging the MPEM. The voltage and current

might be too weak to go through dirty wire pins.

Check carefully if posts show signs of moisture,

corrosion or if they look dull. Clean pins properly

andthencoatthemwithsilicon-baseddielectric

grease or other appropriate lubricant (except if

otherwise specified) when reassembling them. If

the newly replaced MPEM is working, try the old

one and recheck if it works.

NOTE: Ensure that all electronic components

are genuine -- particularly in the ignition system.

Installing resistive caps, non-resistive spark plug

cables (or modified length) or non-resistive spark

plugs may lead to generate fault codes or bad

operation.

NOTE: Use the VCK to diagnose fault codes. See

TROUBLESHOOTING section.

After a problem has been solved, ensure to clear

the fault(s) in the MPEM using the VCK. Refer to

DIAGNOSTIC PROCEDURES.

Resistance Measurement

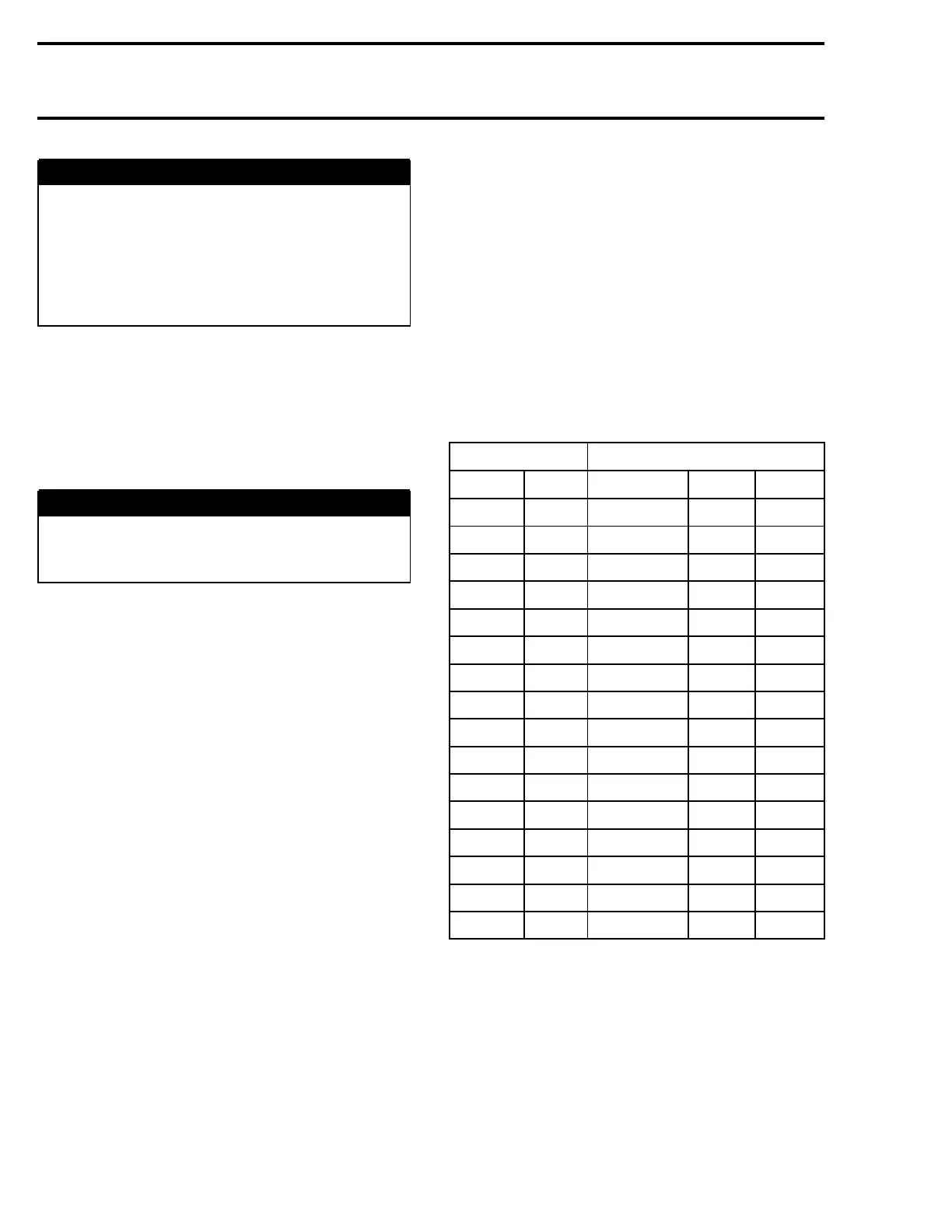

Whenmeasuringtheresistancewithanohmme-

ter, all values are given for a temperature of 20°C

(69°F). The resistance value of a resistance varies

with the temperature. The resistance value for

usual resistor or windings (such as injectors) in-

creases as the temperature increases. However,

our temperature sensors are NTC types (Negative

Temperature Coefficient) and work the opposite

which means that the resistance value decreases

as the temperature increases. Take it into account

when measuring at temperatures different from

20°C(69°F). Use this table for resistance variation

relative to temperature for temperature sensors.

TEMPERATURE RESISTANCE (OHMS)

°C °F NOMINAL LOW HIGH

-30 -22 12600 11800 13400

-20

-4

11400 11000 11800

-10

14

9500 8000 11000

0 32 5900 4900 6900

10 50 3800 3100 4500

20 68 2500 2200 2800

30 86 1700 1500 1900

40 104 1200 1080 1320

50 122 840 750 930

60 140 630 510 750

70 158 440 370 510

80 176 325 280 370

90 194 245 210 280

100 212 195 160 210

110 230

145

125 160

120 248

115

100 125

CONVERSION CHART FOR TEMPERATURE SENSORS

The res

istance value of a temperature sensor may

tes

tgoodatacertaintemperaturebutitmightbe

d

efective at other temperatures. If in doubt, try a

new sensor.

308 smr2004-Complete Line Up

Loading...

Loading...