Section13PROPULSION

Subsection 04 (VARIABLE TRIM SYSTEM)

F01J2GA

Tighten nuts no. 11 to 7 N•m(62lbf•in).

Connect wires of motor.

CAUTION: Make sure wire color codes match.

Install cover no. 7.

NOTE: Make sure seal no. 12 is in place.

INSTALLATION

Installation is essentially the reverse of removal

procedures. However pay particular attention to

the following.

Nut and Sealing Washer

Place sealing washer no. 5 on nut no. 4. Make

sure seal lips are facing toward hull.

F01J2LA

1

2

1. Seal lips facing hull

2. Nut

Apply Loctite Primer N (P/N 293 800 041) to

threads of VTS housing, and to nut no. 4.

Apply Loctite 243 (blue) to nut no. 4.

Install nut with sealing washer and torque to

7N•m(62lbf•in) using the VTS socket tool

(P/N 295 000 133).

Apply synthetic grease to sliding shaft.

Boot and Clamps

Install rubber boot no. 3 over sliding shaft and se-

cure with clamps.

VTS Rod

Install rubber boot no. 3, over sliding shaft and

secure with clamps.

RXP Models

Secure the VTS rod onto the sliding shaft end us-

ing bolt no. 13 and nut no. 14. Torque nut to

7N•m(62lbf•in).

XP DI Models

Install ball joint on LEFT side of sliding shaft no. 10

using bolt no. 13, washers no. 15 and nut no. 14.

Torquenutto10N•m(88lbf•in).

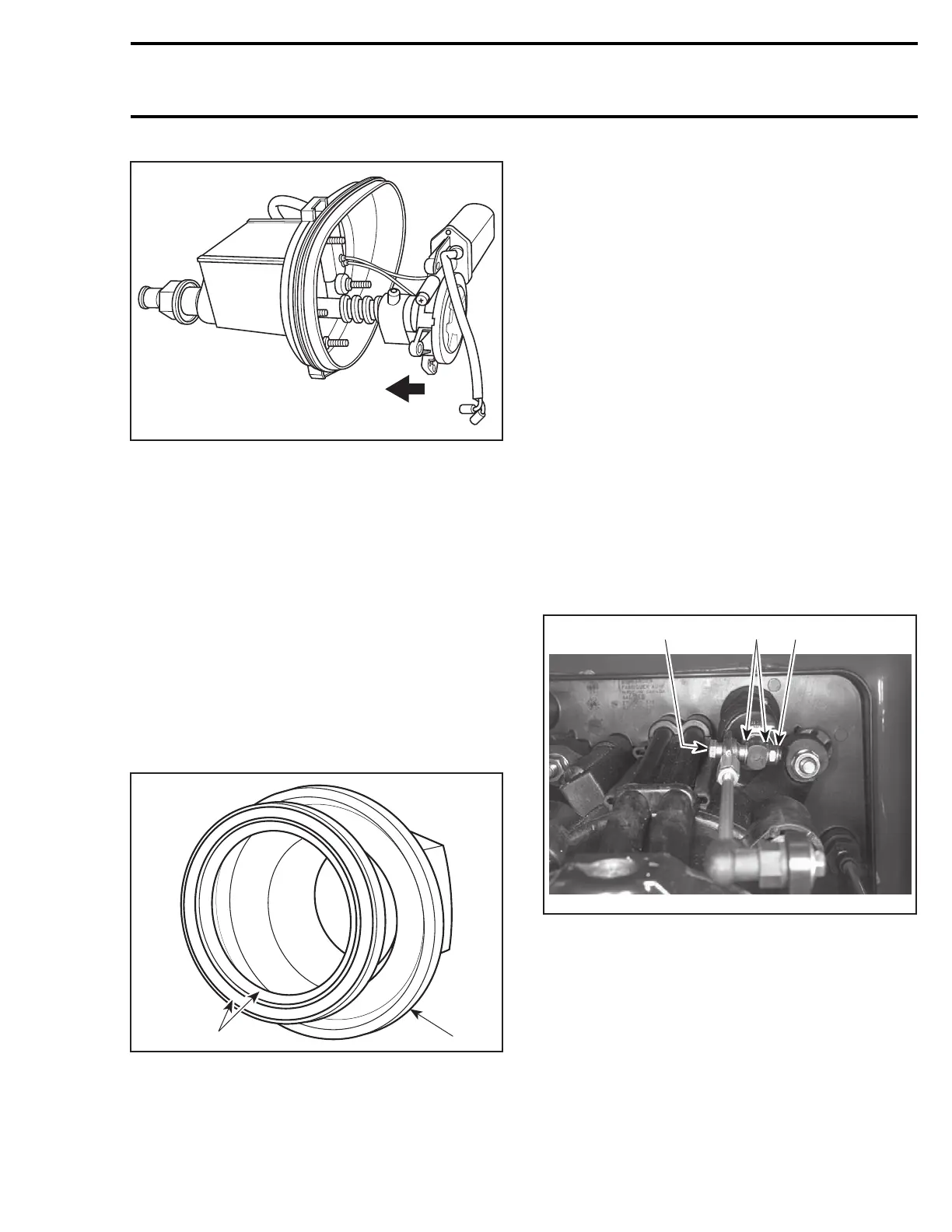

F06J01C

2 13

TYPICAL

1. Washers

2. Bolt

3. Lock nut

ADJUSTMENT

RXP Models

No adjustment is required.

smr2004-Complete Line Up 683

Loading...

Loading...