Section12ELECTRICALSYSTEM

Subsection 02 (CHARGING SYSTEM)

– Set multimeter to Vac scale.

– Start and rev engine to 3500 RPM. The obtained

value should be between 45 and 70 Vac, and

25 Vac on 4-TEC engines.

– If the stator is out of specification, replace it.

Stator

787 RFI Engines

STATIC TEST: CONTINUITY

– Disconnect the magneto wiring harness con-

nector.

– Install the 4-pin magneto harness adapter

(P/N 295 000 131).

– Check resistance between the BLACK/YEL-

LOW and the BLACK wires of the 4-pin magne-

to harness adapter. The resistance should be

between 0.1 to 1.0 ohm.

– Place either meter lead into the RED/BLACK

wire and note the resistance (same as step

no. 3). If the readings are out of specification,

thestatorwillneedtobereplaced.

STATIC TEST: INSULATION

– Disconnect the magneto wiring harness con-

nector.

– Install the 4-pin magneto harness adapter

(P/N 295 000 131) to the magneto wiring har-

ness. Leave wiring harness side disconnected.

– Insert multimeter positive (+) probe to the

BLACK/YELLOW wire of the 4-pin magneto

harness adapter.

– Ground the multimeter negative (-) probe to the

engine or the stator iron core and note the read-

ing.

– Repeat test with the other BLACK and

RED/BLACK wires of the 4-pin magneto har-

ness adapter.

NOTE: There should be no continuity (infinity) be-

tween the stator insulated coils and ground. If

there is a reading, the stator coils and/or the wiring

from the coils is grounded and needs to be re-

placed or repaired.

DYNAMIC TEST — AC Voltage

– Disconnect the voltage regulator/rectifier con-

nectors.

– Disconnect the magneto wiring harness con-

nector.

– Install the 4-pin magneto harness adapter

(P/N 295 000 131) between connectors.

– Connect test probes of the multimeter to the

BLACK/YELLOW and RED/BLACK wires of the

4-pin magneto harness adapter.

– Set multimeter to Vac scale.

– Start and rev engine to 3500 RPM. The obtained

valueshouldbebetween45and70Vac.

– Repeat test with the BLACK wire and either the

RED/BLACK or BLACK/YELLOW wires of the

4-pin magneto harness adapter.

– If the stator is out of specification, replace it.

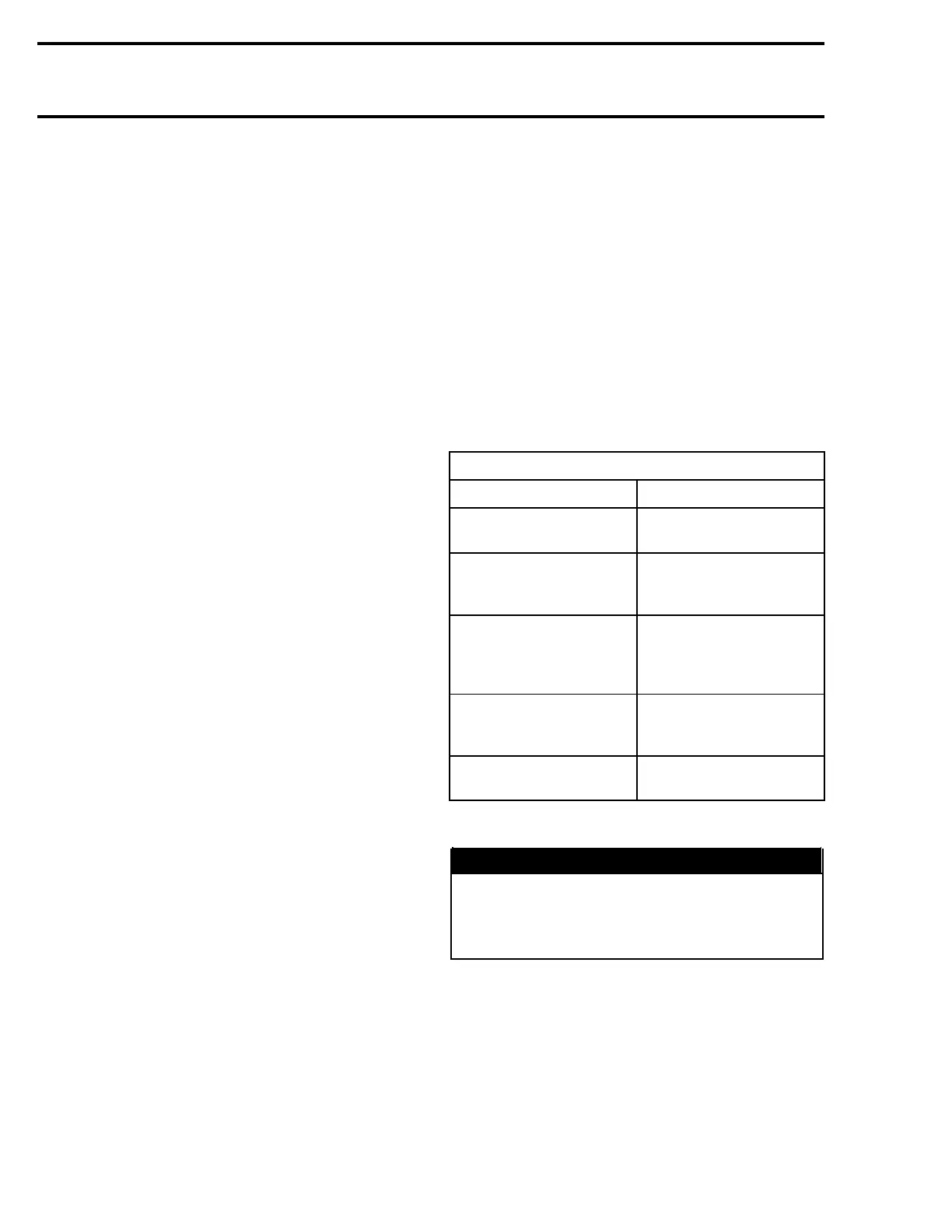

BATTERY

Troubleshooting

SYMPTOM: DISCHARGED OR WEAK BATTERY

CAUSE REMEDY

Battery posts and/or

cable terminal oxidized.

Clean and coat with

dielectric grease.

Loose or bad

connections.

Check wiring and

connector cleanliness,

damaged or short circuit.

Faulty battery (sulfated,

doesn't keep a full

charge, damaged casing,

loose post).

Replace.

Burnt fuse(s) or faulty

rectifier.

First check fuse(s). If

it is in good condition,

check rectifier/regulator.

Faulty battery charging

coil (or stator).

Replace.

Removal

WARNING

Battery BLACK negative cable must always be

disconnected first and connected last. Never

charge or boost battery while installed in wa-

tercraft.

All Models except GTI Series

Proceed as follows:

– Disconnect the BLACK negative cable first.

– Disconnect the RED positive cable last.

– Removetheventlinefromthebattery.

– Remove the holding strap(s).

566 smr2004-Complete Line Up

Loading...

Loading...