Section 08 ENGINE MANAGEMENT (4-TEC)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

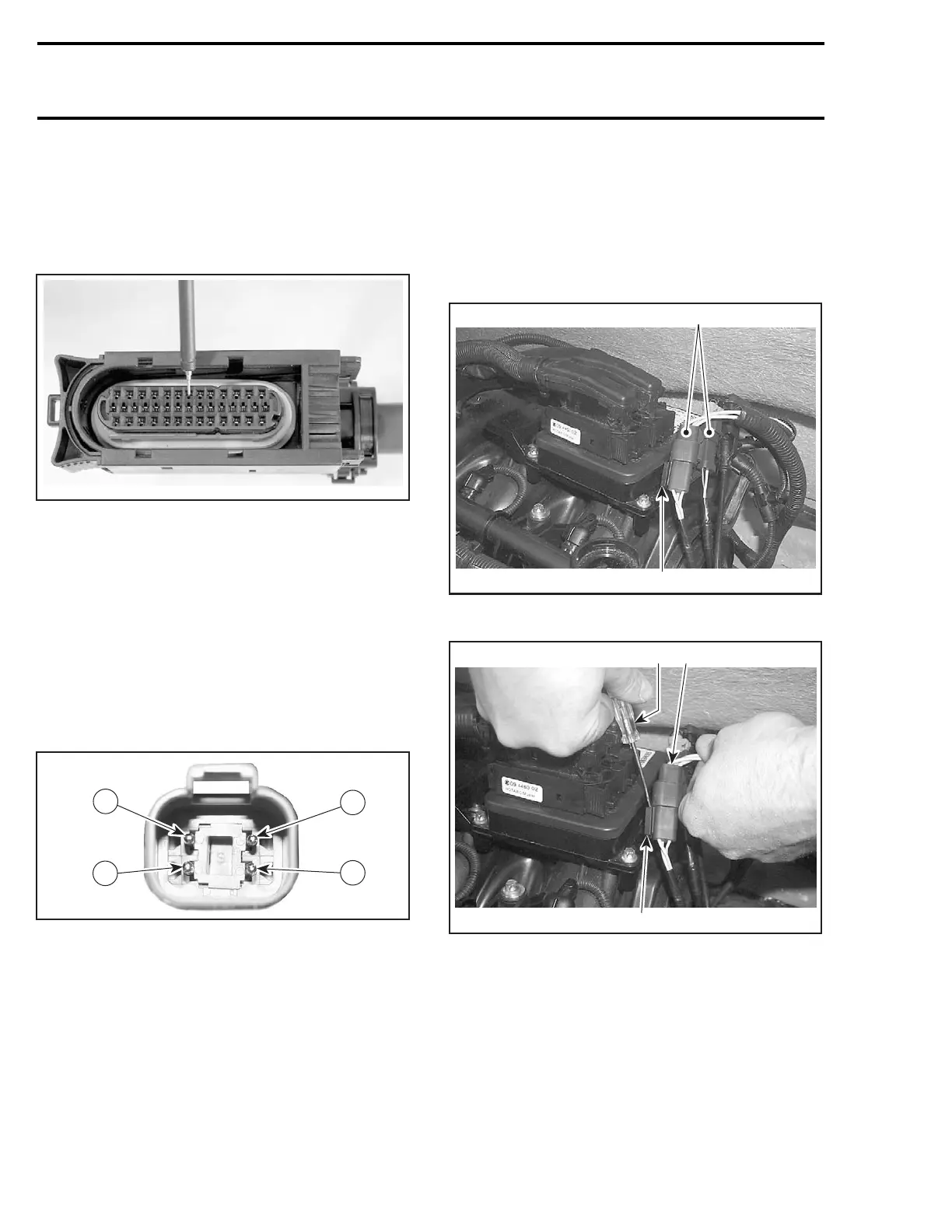

CAUTION: Probe on top of terminal only. Do

not try to probe inside terminal or to use a pa-

per clip to probe inside terminal, it can damage

the square-shaped terminal and this could lead

to unproper function of the engine managment

system.

R1503motr352A

CAUTION: Do not disconnect the ECM connec-

tor needlessly. They are not designed to be dis-

connected/reconnected repeatedly.

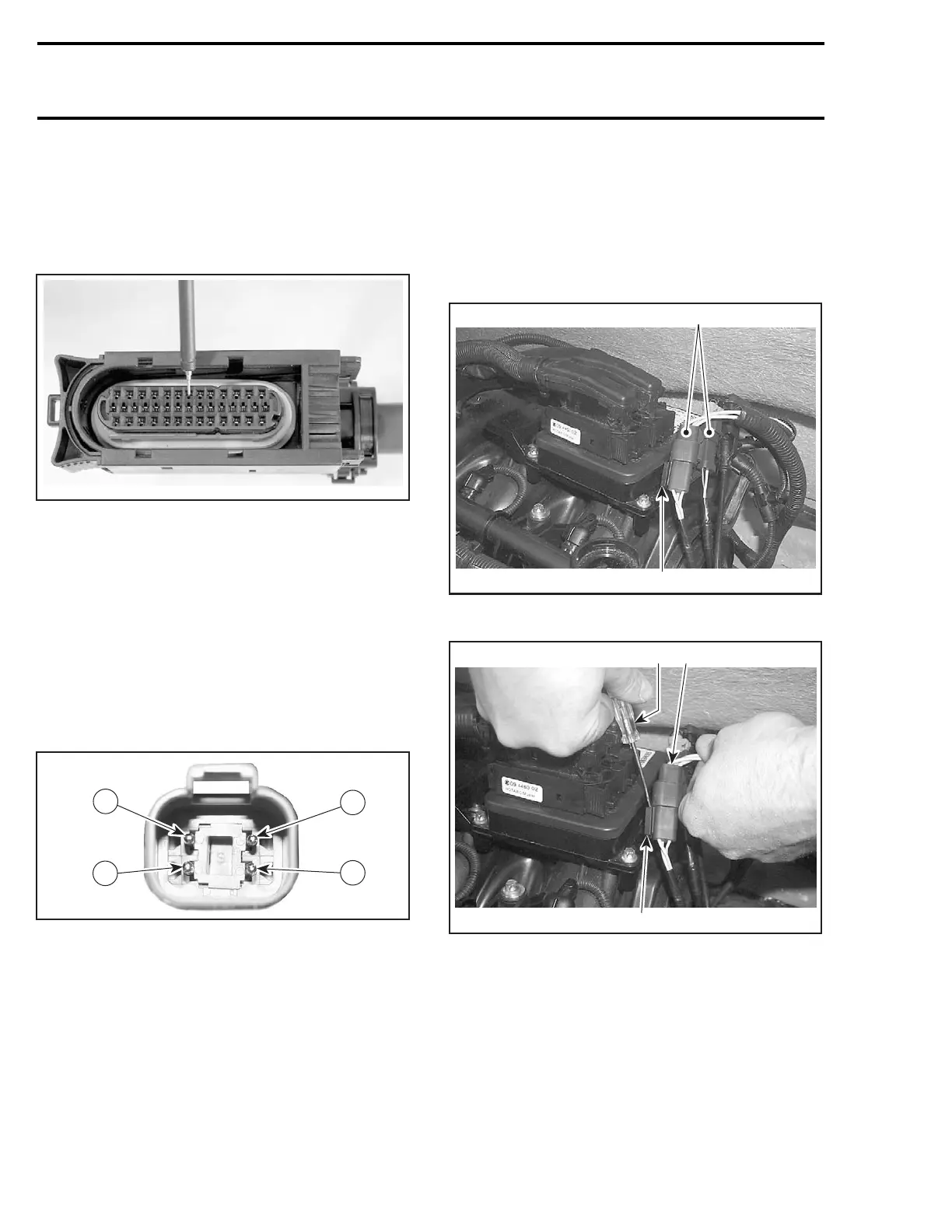

Engine Connector

Use this diagram to locate the terminal numbers

on the Engine connector of the wiring harness

when performing tests.

CAUTION: Before unplugging engine connec-

tor, always remove safety lanyard first then

wait 15 seconds. Otherwise, damage to CAPS

may occur.

4

R1503motr192A

1

2

3

ENGINE CONNECTOR PIN-OUT (WIRING HARNESS SIDE)

CONNECTORS ON ENGINE

Removal

To remove connectors from engine connector

bracket, slide a flat screwdriver between the con-

nector bracket and the connectors and remove

connectors.

1

F18Z0JA

2

1. Engine connector bracket

2. Connectors

1

F18Z0KA

23

1. Engine connector bracket

2. Deutsch connector

3. Flat screwdriver

406 smr2004-Complete Line Up

Loading...

Loading...