Section13PROPULSION

Subsection 01 (JET PUMP)

GENERAL

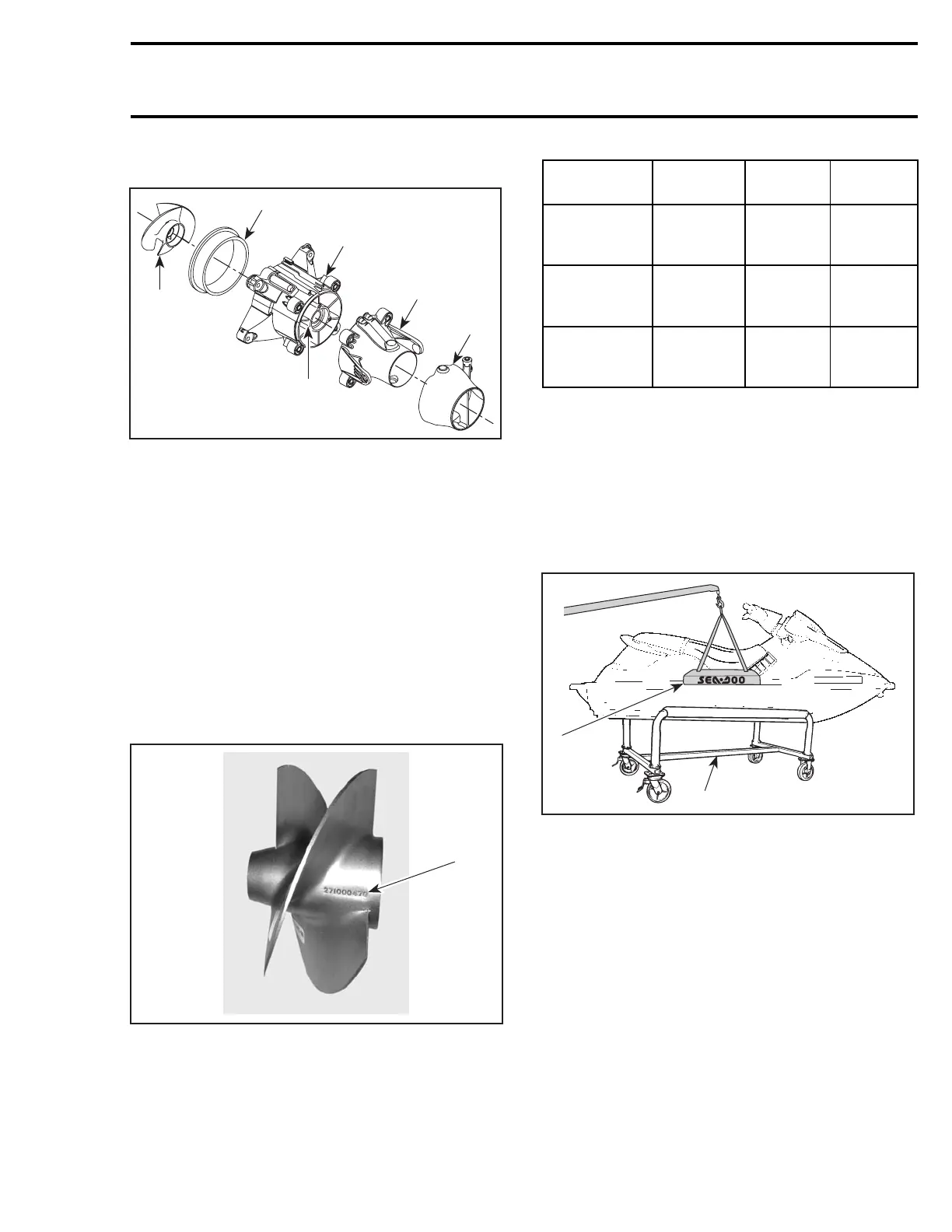

F00J0SA

5

2

1

6

3

4

TYPICAL

1. Nozzle

2. Venturi

3. Jet pump housing

4. Wear ring

5. Impeller

6. Stator

Cleanness Requirements

Hands, tools, bench, rags must be clean before

pump disassembly.

CAUTION: Pump grease tube must be opened

at very last moment to avoid contamination.

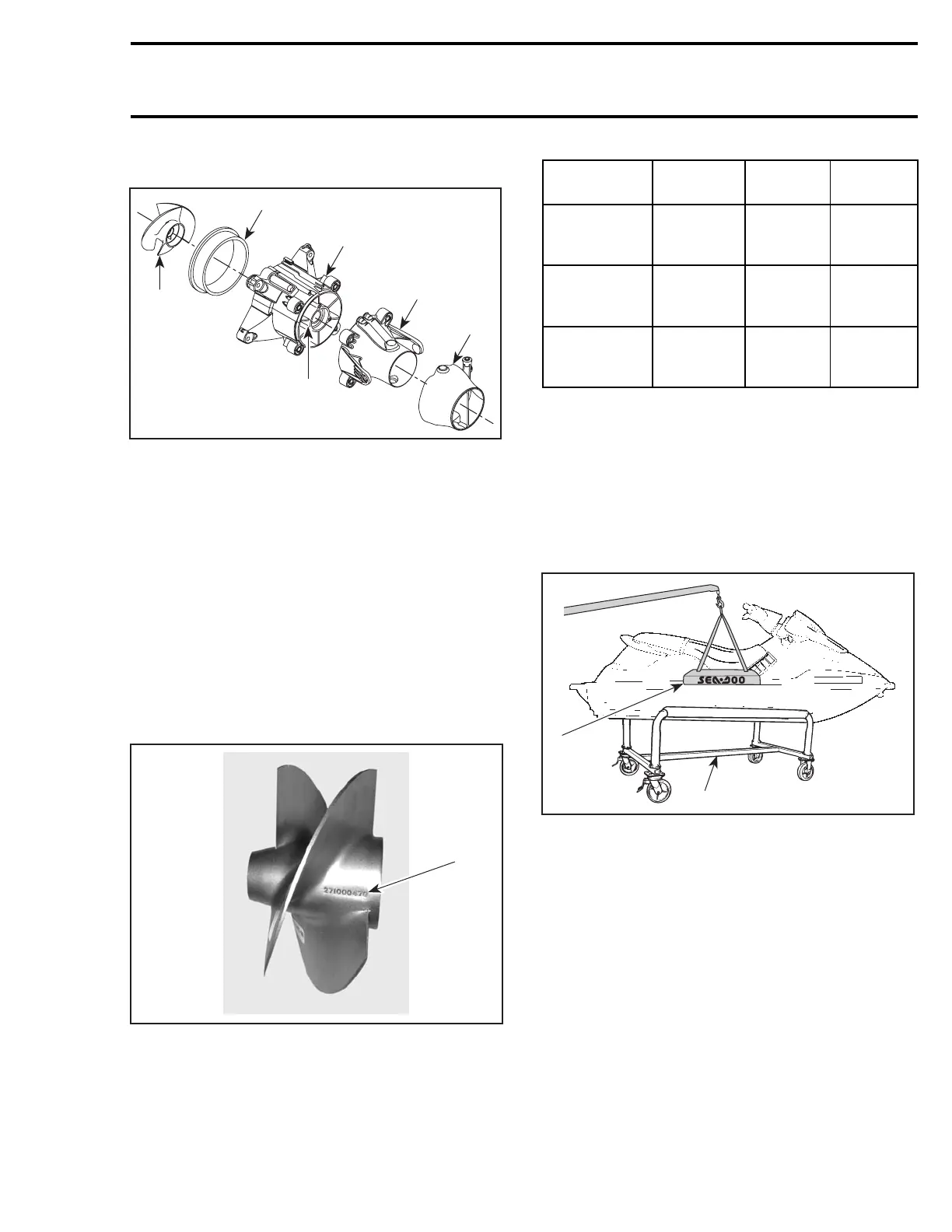

Impeller Identification

To identify the impellers refer to the following il-

lustration and chart.

F02J0VA

1

1. Stamped part number

WATERCRAFT

MODEL

IMPELLER

P/N

MATERIAL PITCH

GTX 4-TEC 271 001 386

Stainless

steel

Progressive

pitch

13° -23°

GTX 4-TEC

Supercharged

267 001 091

Stainless

steel

Progressive

pitch

13° -23°

RXP 267 001 096

Stainless

steel

Progressive

pitch

10° -21°

JET PUMP INSPECTION ON

WATERCRAFT

To work on watercraft, securely install it on a

stand. Thus, if access is needed to water inlet

area, it will be easy to slide underneath watercraft.

A lift kit (P/N 295 100 205) can be used to install

watercraft on a stand.

F01J42A

1

2

TYPICAL

1. Lift kit

2. Work stand

Impeller Condition

Condition of impeller no. 3,bootno. 2 and ring

no. 1 can be quickly checked from underneath of

the watercraft. Remove grate and look through

water inlet opening.

smr2004-Complete Line Up 637

Loading...

Loading...