Section 05 ENGINE (4-TEC)

Subsection 06 (LUBRICATION SYSTEM)

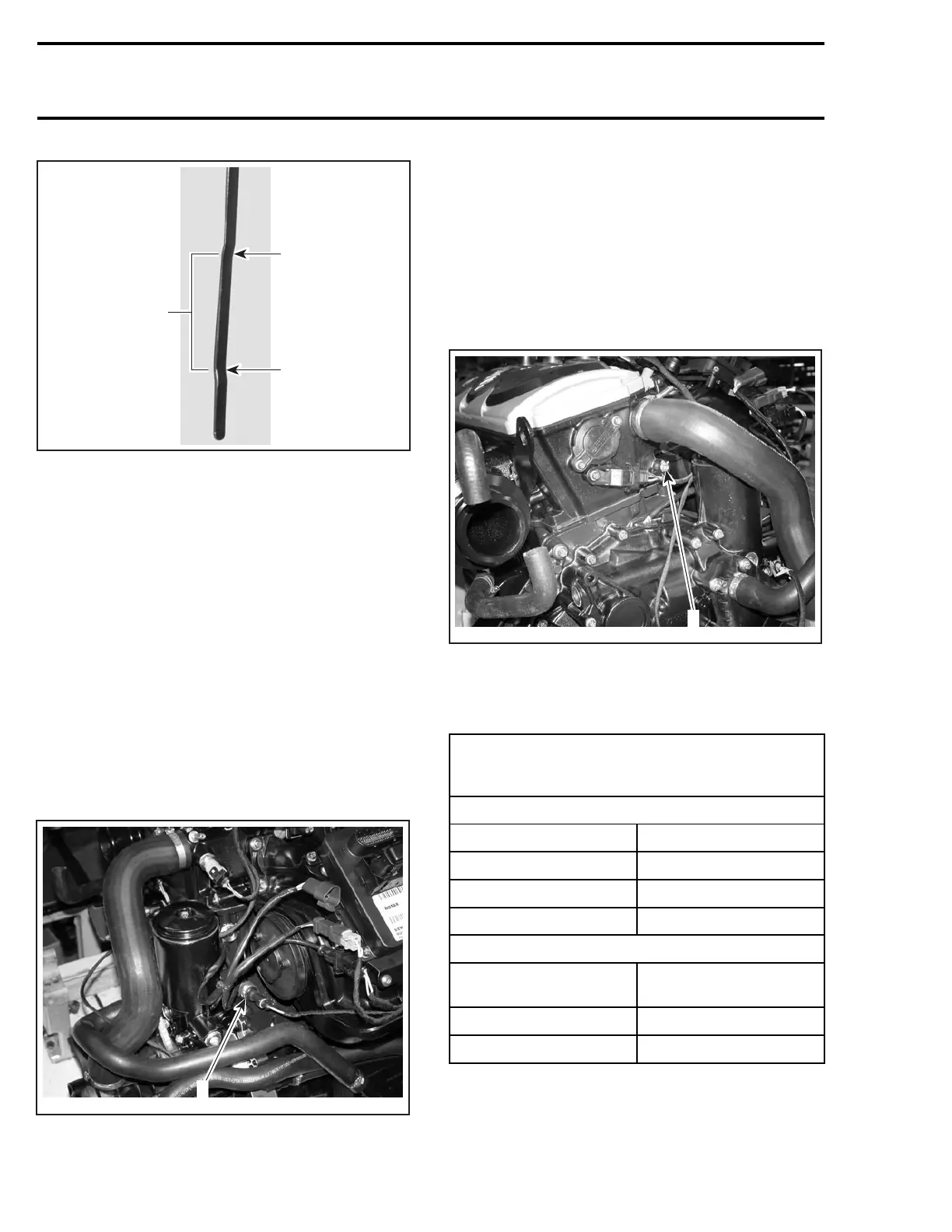

F18D2MA

1

2

3

1. Full

2. Add

3. Operating range

– Otherwise, add oil until its level is between

marks as required.

– To add oil, unscrew oil cap. Place a funnel into

the opening and add the recommended oil to

the proper level. Do not overfill.

ENGINE OIL PRESSURE TEST

NOTE: The engine pressure test should be done

with a warm engine and the recommended oil.

Use oil pressure gauge (P/N 529 035 709) and

hose adaptor (P/N 529 035 652) and install where

shown. A 1/8 NPT pipe extension may ease the

installation.

Remove oil pressure switch.

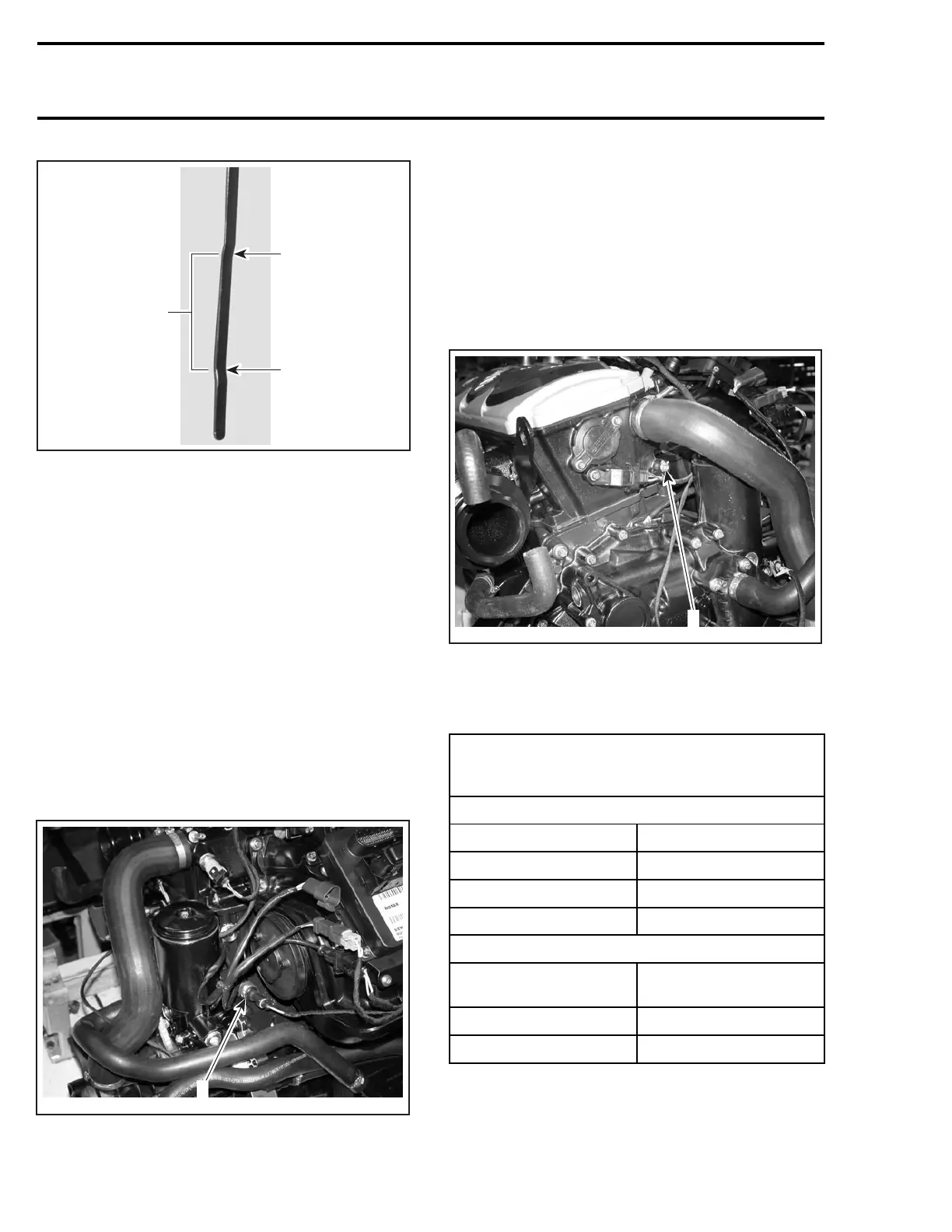

F18D2YA

1

1. Remove oil pressure switch and install gauge here

To prevent the EMS to go in limp home mode (at

2500 RPM) or to generate a fault code, start en-

gine, THEN ground OPS connector to engine.

You may find easier on supercharged engines to

removetheplugfromtheendofenginehead.

However, the pressure readings will be different.

Use the proper table below.

NOTE: The pressure may be measured from cylin-

der head on all 4-TEC engines if desired.

F18D2ZA

1

1. Remove this plug and install gauge here

Start engine and read pressure at different RPM

as per following tables.

OIL PRESSURE

MEASURED AT PRESSURE

SWITCH LOCATION

4-TEC NATURALLY ASPIRATED ENGINES

ENGINE RPM PRESSURE kPa (PSI)

Idle (cold) 296 - 400 (43 - 58)

Idle (at 80°C(176°F)

Min. 160 (23)

4000 - 7500 296 - 400 (43 - 58)

ALL 4-TEC SUPERCHARGED ENGINES

Idle (cold)

448 - 648 (65 - 94)

foraveryshorttime

Idle (at 80°C(176°F)

Min. 228 (33)

4000 - 7500 400 - 496 (58 - 72)

238 smr2004-Complete Line Up

Loading...

Loading...