Section 08 ENGINE MANAGEMENT (4-TEC)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

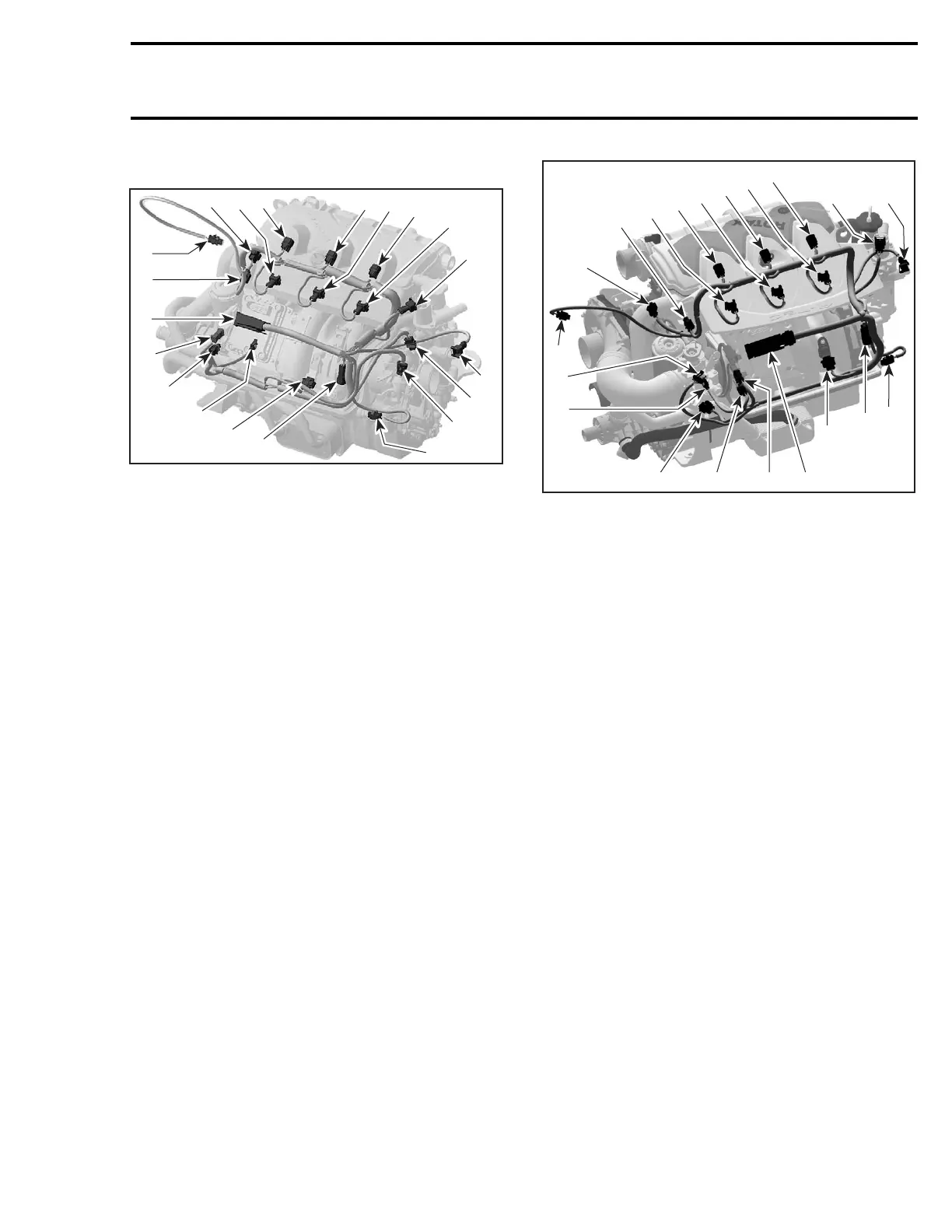

ENGINE WIRING HARNESS

4

R1503motr199A

5

6

78

10

9

11

12

3

2

1

19

20

18

17

14

13

15

16

4-TEC ENGINES

1. ECM connector

2. CTS connector

3. EGTS connector

4. CAPS connector

5. Fuel injector connector (cylinder 1)

6. Ignition coil connector (cylinder 1)

7. Fuel injector connector (cylinder 2)

8. Ignition coil connector (cylinder 2)

9. Fuel injector connector (cylinder 3)

10.Ignition coil connector (cylinder 3)

11. TOPS valve connector

12.OSPS connector

13.TPS connector

14.Idle bypass valve connector

15.MATS connector

16. Engine connector

17.MAPS connector

18.OPS connector

19.KS connector

20. CPS connector

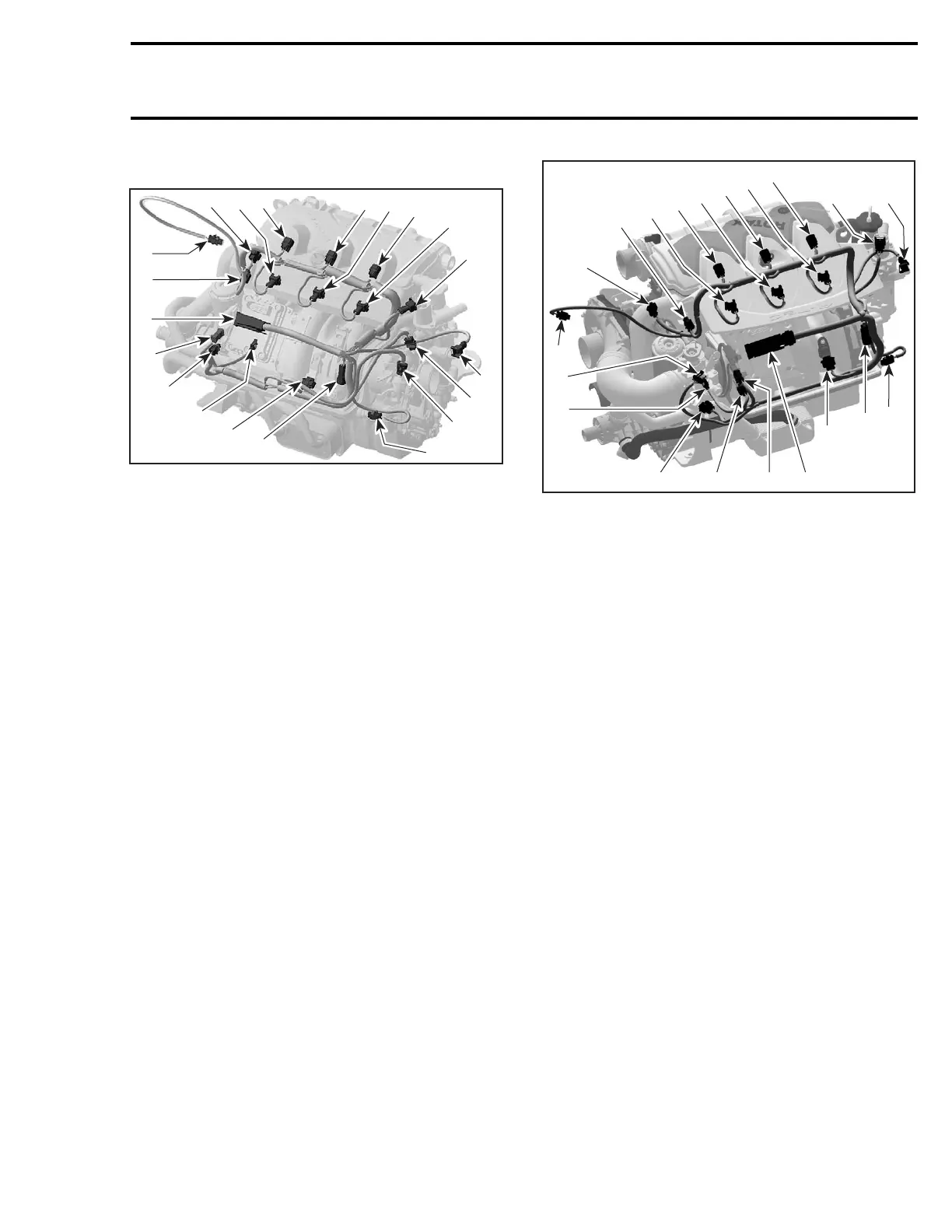

13

4

R1503motr270A

3

2

5

6

7

8

9

10

11

12

14

18

19 20 1

16

15

17

ALL 4-TEC SUPERCHARGED ENGINES

1. ECM connector

2. CTS connector

3. EGTS connector

4. CAPS connector

5. Fuel injector connector (cylinder 1)

6. Ignition coil connector (cylinder 1)

7. Fuel injector connector (cylinder 2)

8. Ignition coil connector (cylinder 2)

9. Fuel injector connector (cylinder 3)

10. Ignition coil connector (cylinder 3)

11.TOPS valve connector

12.OSPS connector

13. TPS connector

14.Idle bypass valve connector

15. MATS connector

16. Engine connector

17.MAPS connector

18.OPS connector

19. KS connector

20.CPS connector

Resistance Test

Check continuity of the circuits according to the

wiring diagram in the WIRING DIAGRAMS section

of this manual.

If wiring harness is good, check the respective

sensor/actuator as described in this section.

Otherwise, repair the connectors, replace the

wiring harness or the ECM/MPEM as diagnosed.

Removal

Remove fuel rail cover.

Disconnect the wiring harness from all sensors/ac-

tuators.

Disconnect the ECM connector from the ECM.

Cut all tie raps which are holding the wiring har-

ness in position.

smr2004-Complete Line Up 419

Loading...

Loading...