Section12ELECTRICALSYSTEM

Subsection 01 (IGNITION SYSTEM)

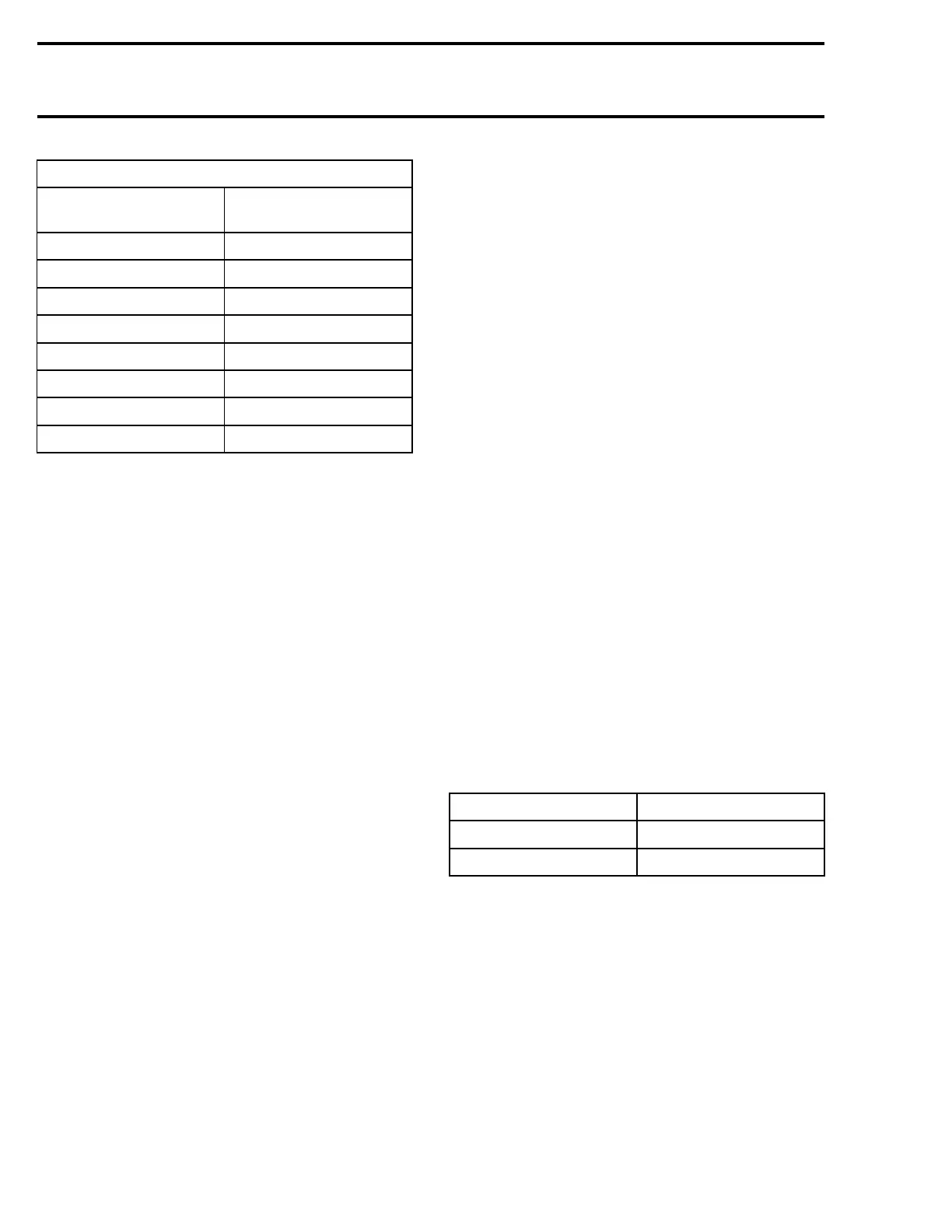

TIMING CORRECTION CHART 787 RFI

MPEM PROGRAMMER

NUMBER

IGNITION TIMING

CORRECTION

1

4.50°

2 3.75°

3 3°

4

2.25°

5

.75°

6 0°

7

-0.75°

8 -2.25°

Ignition timing is set at 12° BTDC at any RPM,

when the Fixed Timing function is active.

PROCEDURE

All Engines

When dealing with ignition problems, the follow-

ing items should be verified in this order:

1) Spark occurrence/spark plug condition.

2) Battery condition.

3) Electrical connections.

4) Engine start/stop switch.

5) Safety lanyard switch.

6) Power supply cut-off relay.

7) Multi-Purpose Electronic Module (MPEM).

8) Magneto output (717 engines).

9) Ignition coil output.

CAUTION: Whenever replacing a component in

ignition system, check ignition timing.

NOTE: To perform verification, a good quality

multimeter such as Fluke 111 (P/N 529 035 868)

should be used.

Engine Start/Stop Switch Verification

Disconnect the YELLOW/RED wire of the

start/stop switch. Using an ohmmeter, con-

nect test probes to YELLOW/RED wire and to

ground.

Measure resistance, it must be an open cir-

cuit (switch is normally open). Depress and hold

switch, the ohmmeter should read close to 0 ohm.

Safety Lanyard Switch Verification

NOTE: The safety lanyard also controls the power

supply cut-off relay. Refer to INSTRUMENTS AC-

CESSORIES for its testing procedure.

If 2 short beeps are not heard when installing the

safety lanyard, refer to DIGITALLY ENCODED SE-

CURITY SYSTEM.

The following continuity tests can also be per-

formed using an ohmmeter:

Disconnect switch wires.

Safety Lanyard Removed

Connect test probes to switch BLACK and

BLACK/YELLOW wires. Measure resistance,

there should be no continuity (open circuit).

Connect one test probe to the WHITE/GRAY wire

and the other test probe to the switch terminal.

Measure resistance, it must be close to 0 ohm.

Connect one test probe to the BLACK wire and

the other test probe to the switch ring. Measure

resistance, it must be close to 0 ohm.

SafetyLanyardonSwitch

Connect test probes to switch BLACK and BLACK/

YELLOW wires. Measure resistance, it must be

close to 0 ohm.

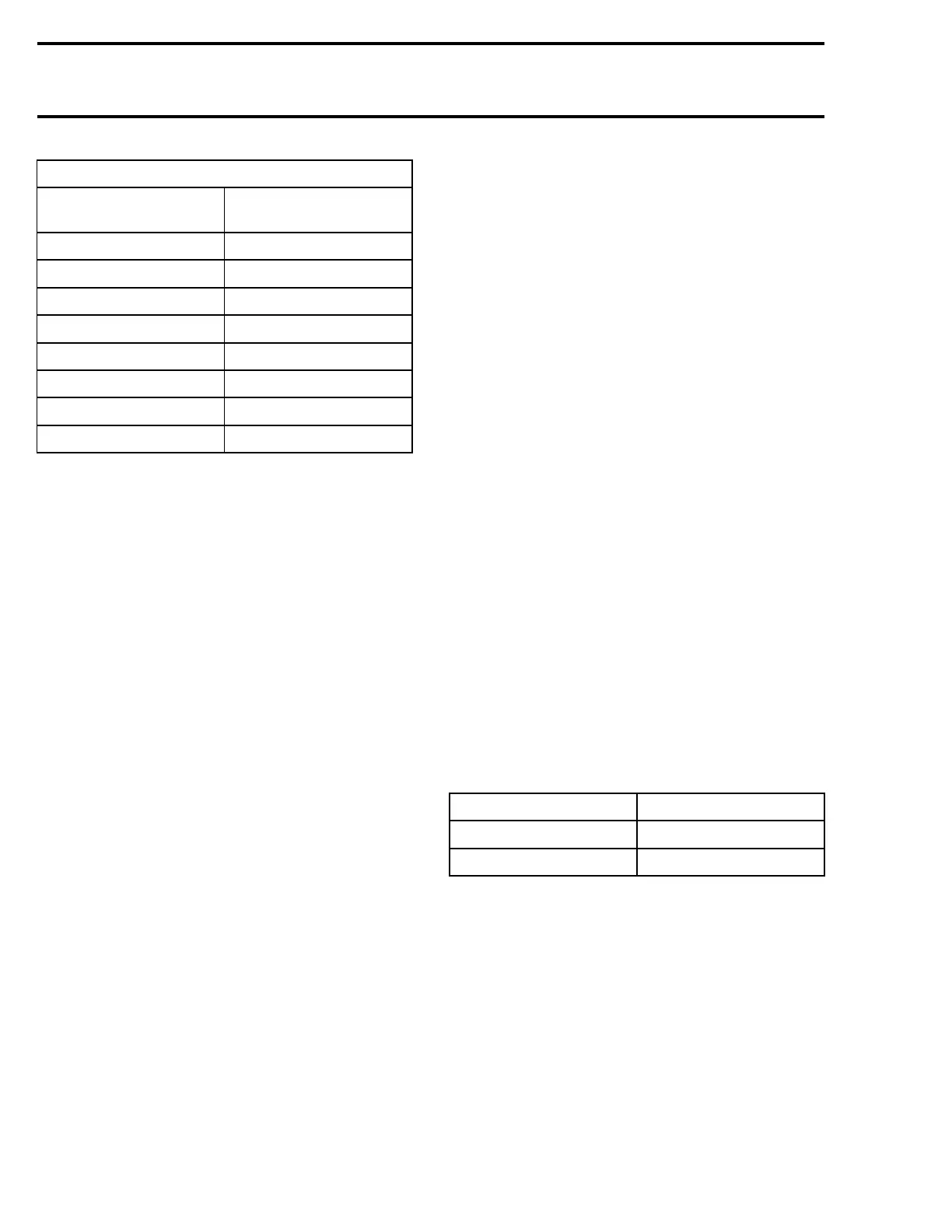

Rev Limiter Verification

To check engine rev limiter, connect an induction

tachometer (P/N 529 014 500), start engine and

check its maximum speed.

MODEL RPM LIMITER SETTING

717

7100 ± 50

787 RFI 7200 ± 50

Multi-Purpose Electronic Module

(MPEM) Verification

It is not possible to accurately check the MPEM

condition without specialized tools. Therefore, re-

place MPEM with a good known unit to conduct

testing.

NOTE: Before replacing the MPEM, make sure all

connectors are properly secured and there is no

water in connectors. Check also the signal and

power contacts in the AMP plug connectors. See

WIRING DIAGRAMS.

552 smr2004-Complete Line Up

Loading...

Loading...