Section 04 ENGINE (2-STROKE)

Subsection 07 (EXHAUST SYSTEM)

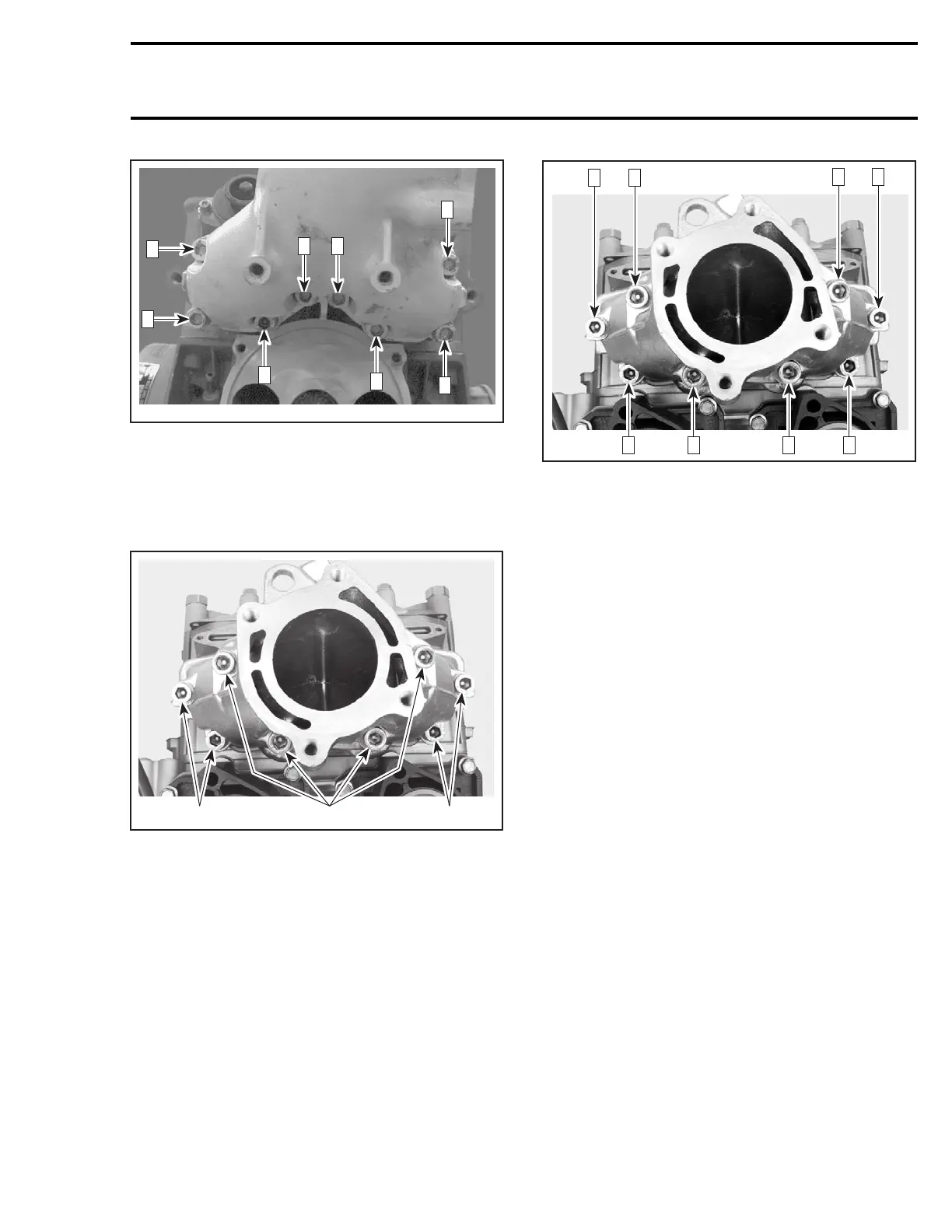

F01D82A

3

1

7 6

4

8

2

5

947 DI Engines

Apply Molykote 111 on threads of Allen screws

no. 12.

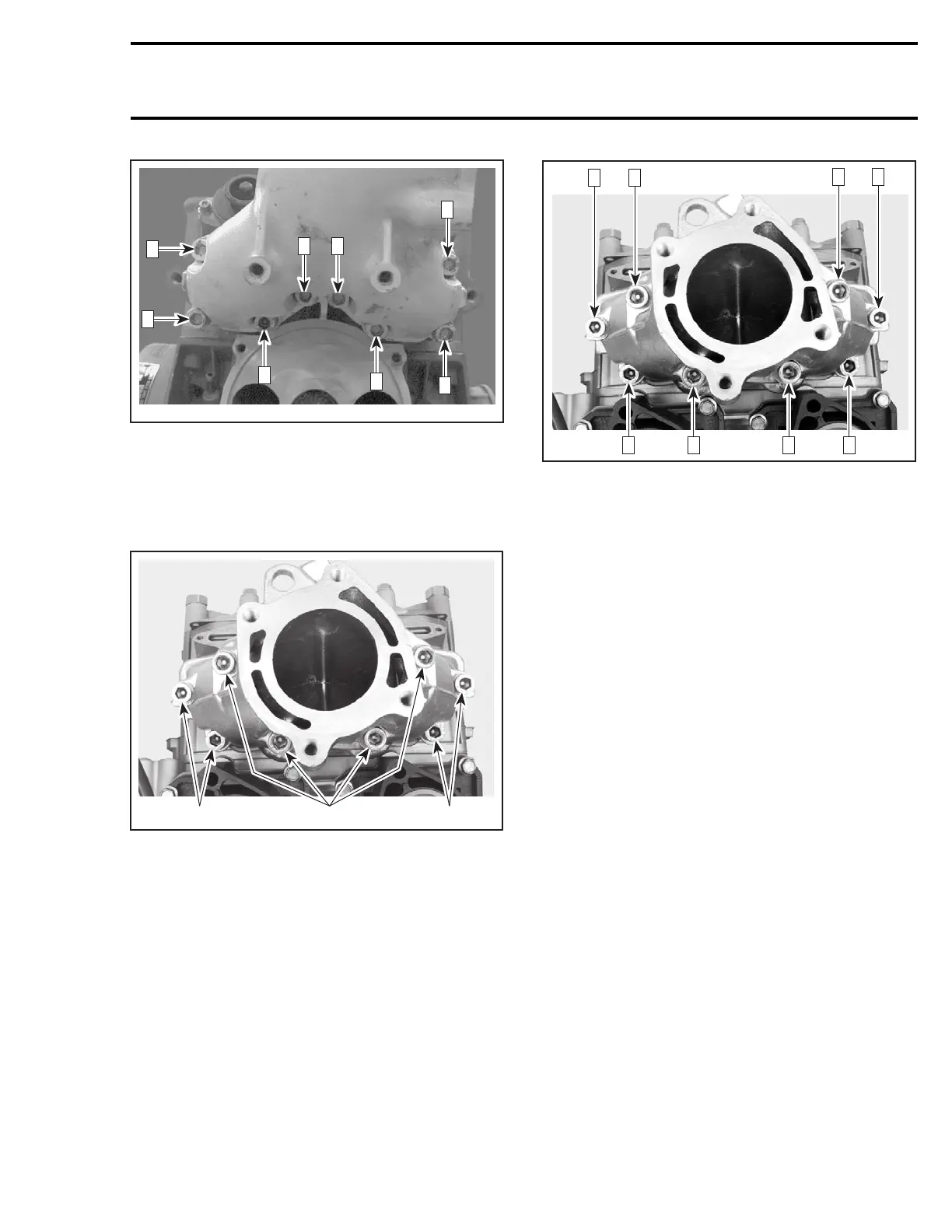

Install and hand tighten Allen screws no. 12 as per

following picture.

F06D1YA

1

2 1

1. M10x60Allenscrews

2. M10x110Allenscrews

Torque Allen screws to 24 N•m(17lbf•ft) as

per following illustrated sequence. Repeat the

procedure, retightening Allen screws to 40 N•m

(30 lbf•ft).

F06D1YB

7 4 1 5

8 2

3 6

Muffler

XP DI Models

At muffler reinstallation, ensure to properly posi-

tion fuel tank paddings so that fuel tank is centered

relatively to drive shaft. Secure straps.

Perform a fuel tank pressure test. Refer to FUEL

SYSTEM.

Tuned Pipe

717 Engines

CAUTION: Torque wrench tightening specifi-

cations must be strictly adhered to. Locking

devices (ex.: locking tabs, elastic stop nuts,

self-locking fasteners, etc.) must be installed

or replaced with new ones where specified. If

the efficiency of a locking device is impaired, it

must be renewed.

Ensure rubber bushings no. 19 and sleeve no. 18

are not damaged and are properly installed into

tune pipe support(s).

CAUTION: Damage to bushings and/or sleeve

will eventually cause stress to tuned pipe and

may cause cracking.

Make sure that gasket no. 16 is properly located

on exhaust manifold prior to finalizing pipe instal-

lation.

Apply Loctite 243 (blue) on nut no. 8 and screws

no. 6 and no. 12.

NOTE: Hand tighten all fasteners before torquing

any of them. For torquing sequence, see the fol-

lowing illustrations.

smr2004-Complete Line Up 175

Loading...

Loading...