Section 04 ENGINE (2-STROKE)

Subsection 07 (EXHAUST SYSTEM)

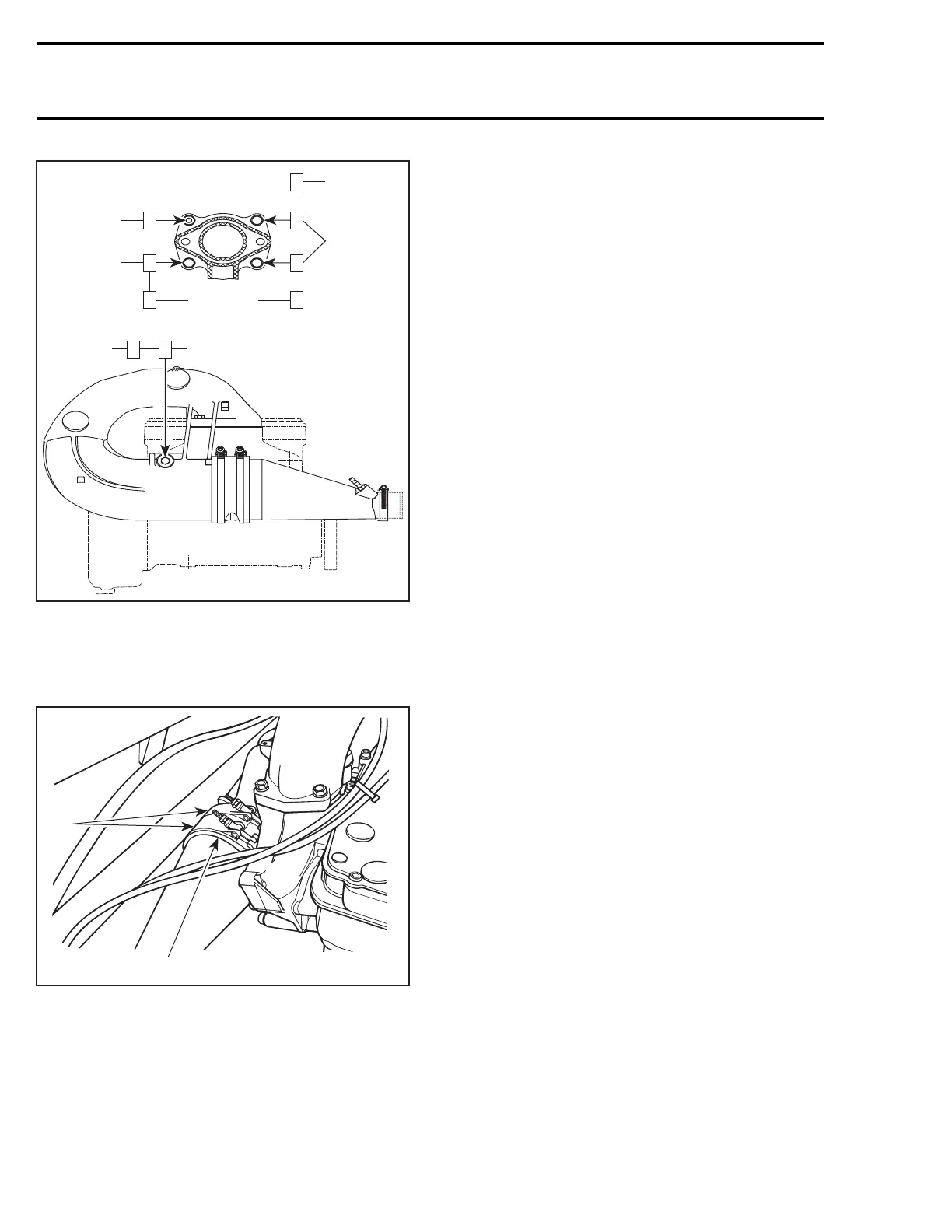

25 Nm

(18 lbfft)

F00D29B

25 Nm

(18 lbfft)

5

1

2

3

4

8

7

50 Nm

(37 lbfft)

6

50 Nm

(37 lbfft)

9

50 Nm

(37 lbfft)

24 Nm

(17 lbfft)

12 Nm

(9 lbfft)

Install tuned pipe cone no. 5 with sealing ring

no. 15 and clamp no. 4.

Position clamp no. 4 as illustrated. Do not tighten

clamp yet.

F01D41A

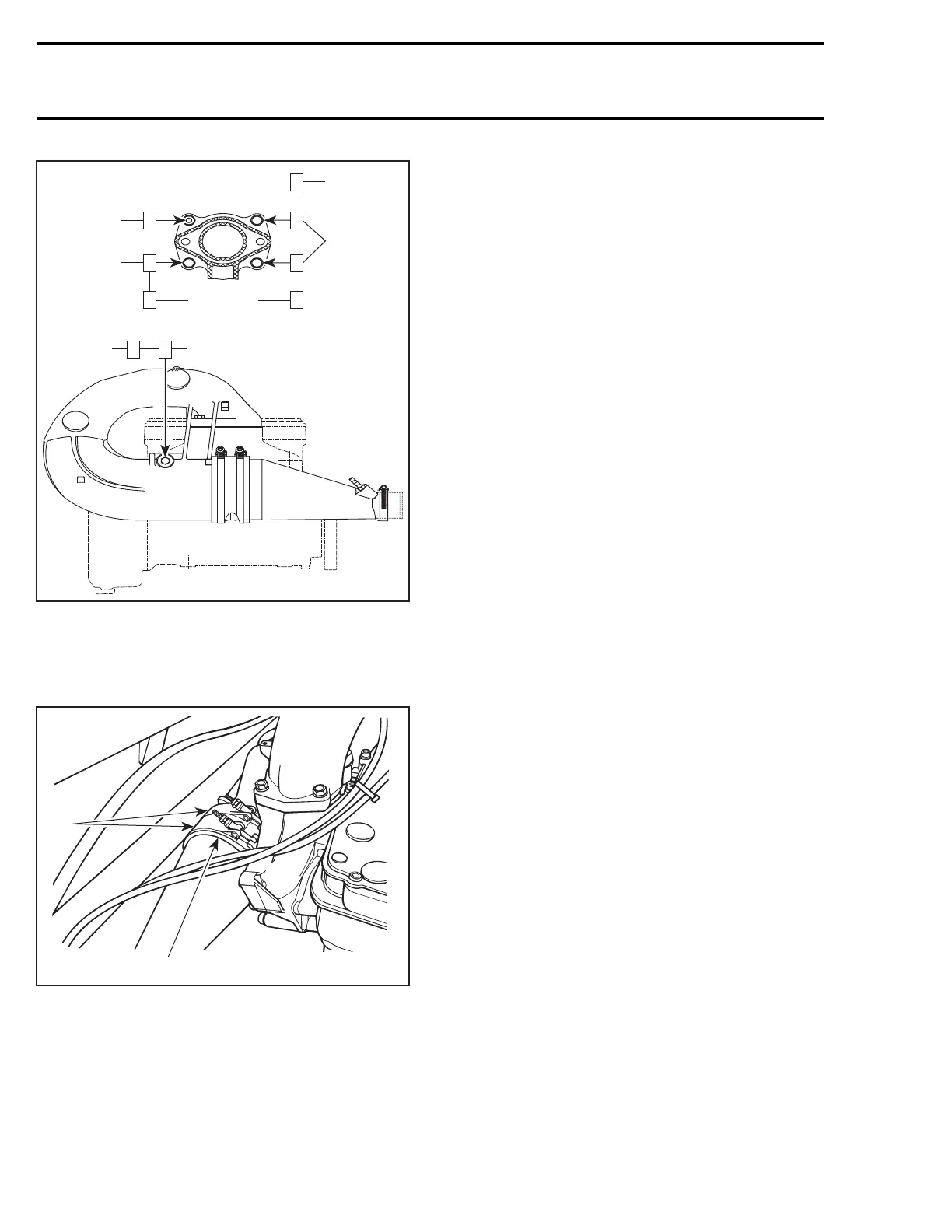

1

2

1. Clamp

2. Exhaust collar

With hose removed, align cone outlet with muffler

inlet.

NOTE: Due to exhaust cone angle, it may have to

be rotated to obtain alignment.

Push cone no. 5 until it touches tuned pipe, then

tighten exhaust clamp no. 4 andtorqueto4N•m

(35 lbf•in).

CAUTION: There must be no gap between

tuned pipe cone and tuned pipe head.

NOTE: Exhaust clamp nuts should be tightened al-

ternately to assure no leakage and to obtain spec-

ified torque.

787 RFI Engines

CAUTION: Torque wrench tightening specifi-

cations must be strictly adhered to. Locking

devices (ex.: locking tabs, elastic stop nuts,

self-locking fasteners, etc.) must be installed

or replaced with new ones where specified. If

the efficiency of a locking device is impaired, it

must be renewed.

NOTE: Loosen all pipe supports from engine be-

fore installing tuned pipe.

Ensure rubber bushings no. 19 and sleeve no. 18

are not damaged and are properly installed into

tune pipe support(s).

CAUTION: Damage to bushings and/or sleeve

will eventually cause stress to tuned pipe and

may cause cracking.

Make sure that gasket no. 16 is properly located

on exhaust manifold prior to finalizing pipe instal-

lation.

Install the tuned pipe end into exhaust hose no. 3.

Do not torque yet.

Torquing Sequence

CAUTION: Torque the tuned pipe in accordance

with the following sequence, otherwise serious

engine damage may occur.

176 smr2004-Complete Line Up

Loading...

Loading...