Section 08 ENGINE MANAGEMENT (4-TEC)

Subsection 03 (DIAGNOSTIC PROCEDURES)

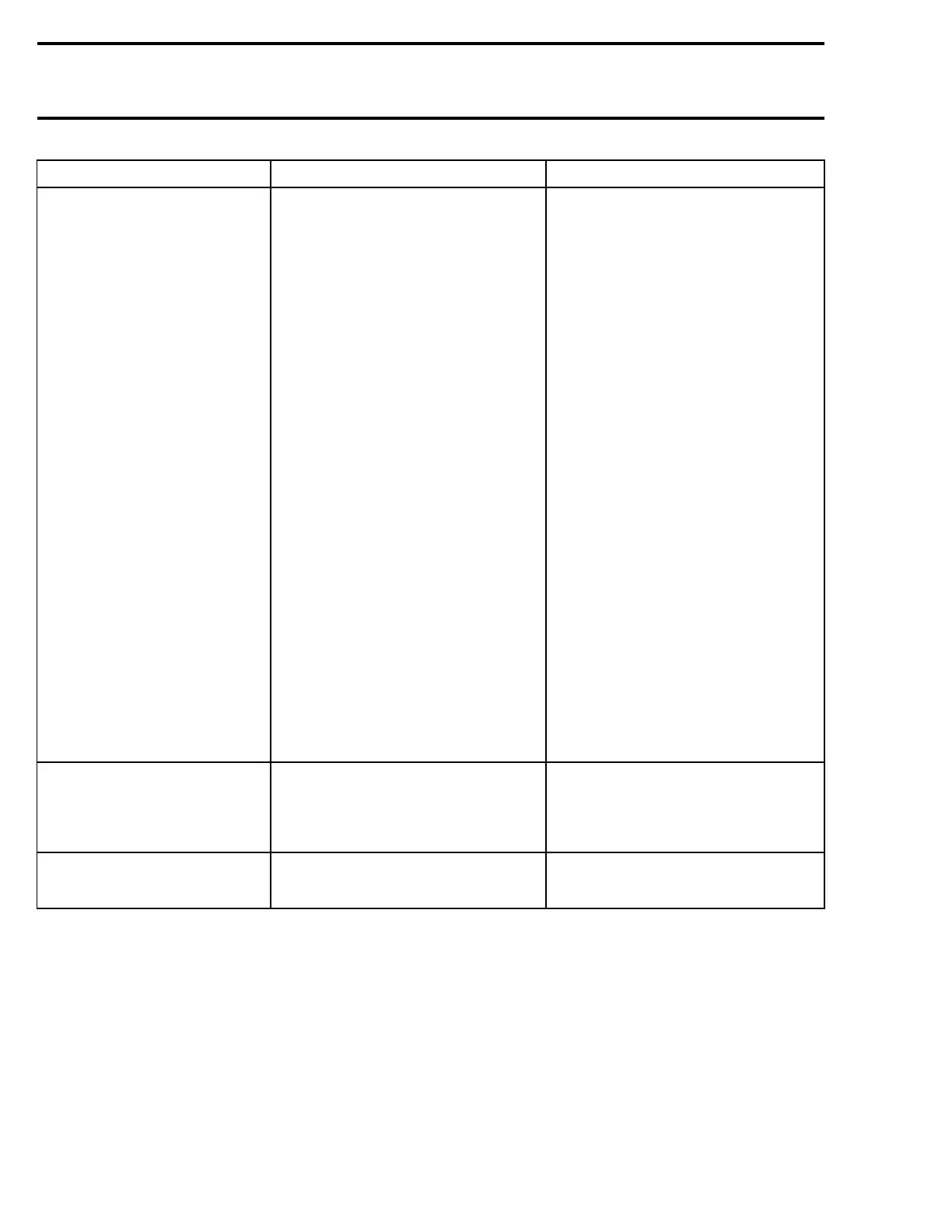

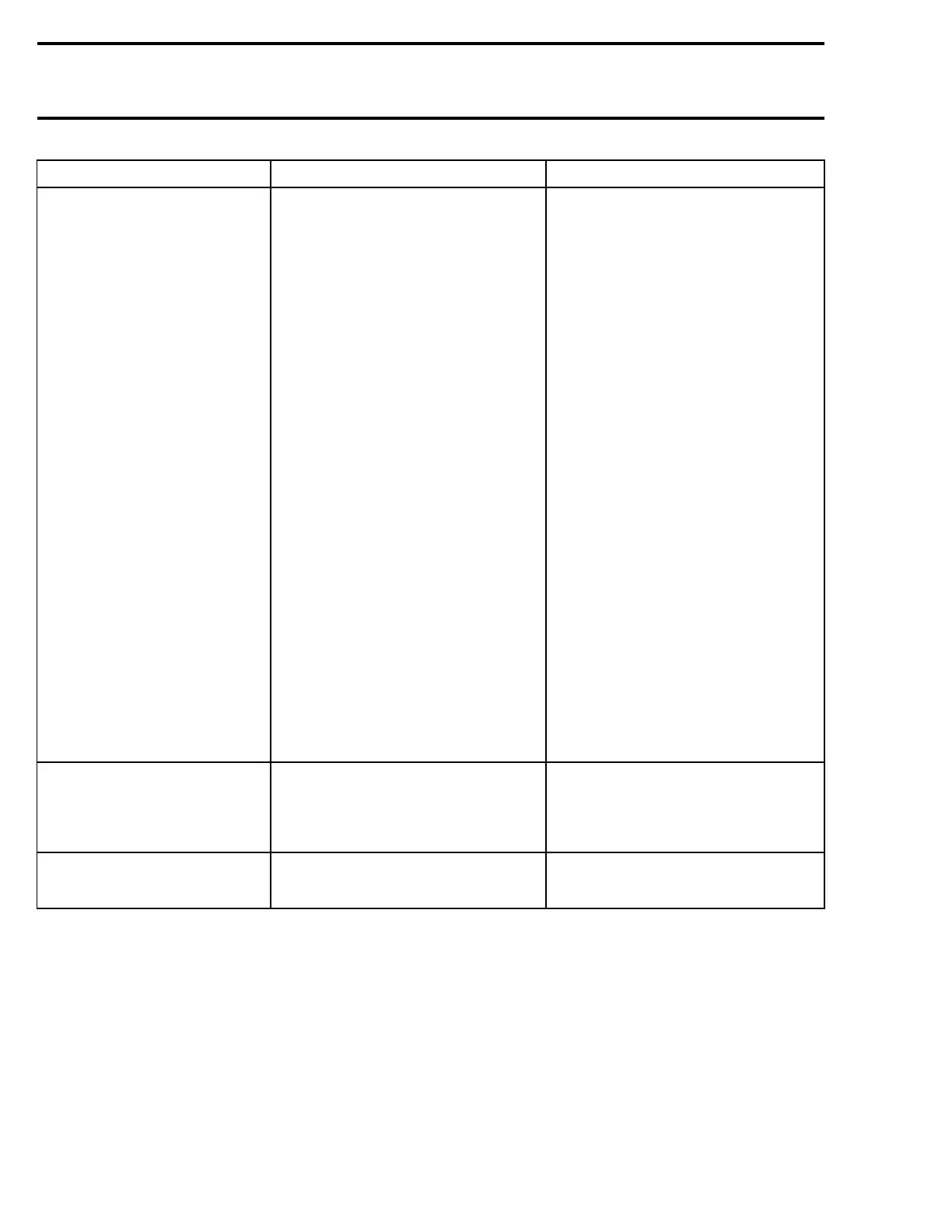

CODED SIGNALS POSSIBLE CAUSE REMEDY

• Watercraft is upside down. Turn watercraft upright. If it does not

work, check the TOPS switch. Refer

to ENGINE MANAGEMENT section.

• Engine coolant temperature sensor

or circuit mal- function.

Refer to ENGINE MANAGEMENT

section.

• Exhaust temperature sensor or

circuit malfunction.

Refer to ENGINE MANAGEMENT

section.

• Engine oil pressure sensor or circuit

malfunction.

Refer to ENGINE MANAGEMENT

section.

• Out of range pressure in oil

separator tank (engine oil leak).

Refer to ENGINE MANAGEMENT

section.

• TOPS sensor or circuit malfunction. Refer to ENGINE MANAGEMENT

section.

• TOPS valve solenoid or circuit

malfunction.

Refer to ENGINE MANAGEMENT

section.

• Starter solenoid circuit malfunction. Refer to ENGINE MANAGEMENT

section.

• Communication link fault detected

by MPEM.

Refer to ENGINE MANAGEMENT

section.

• ECM communication link message

missing (detected by MPEM).

Refer to ENGINE MANAGEMENT

section.

• Information center communication

link message missing (detected by

MPEM).

Refer to ENGINE MANAGEMENT

section.

2 seconds beep every 1 minute

interval.

• Bilge pump circuit low or high

voltage (

if so equipped

).

Refer to ENGINE MANAGEMENT

section.

• Low fuel level.

Refer to INSTRUMENTS AND

ACCESSORIES section.

A 2 seconds beep every

5 minutes interval.

• Fuel tank level sensor or circuit

malfunction.

Refer to INSTRUMENTS AND

ACCESSORIES section.

• High engine coolant temperature.

Refer to COOLING SYSTEM.Continuously beeps.

• High exhaust temperature.

Refer to COOLING SYSTEM.

442 smr2004-Complete Line Up

Loading...

Loading...