Section12ELECTRICALSYSTEM

Subsection 01 (IGNITION SYSTEM)

Secondary Winding

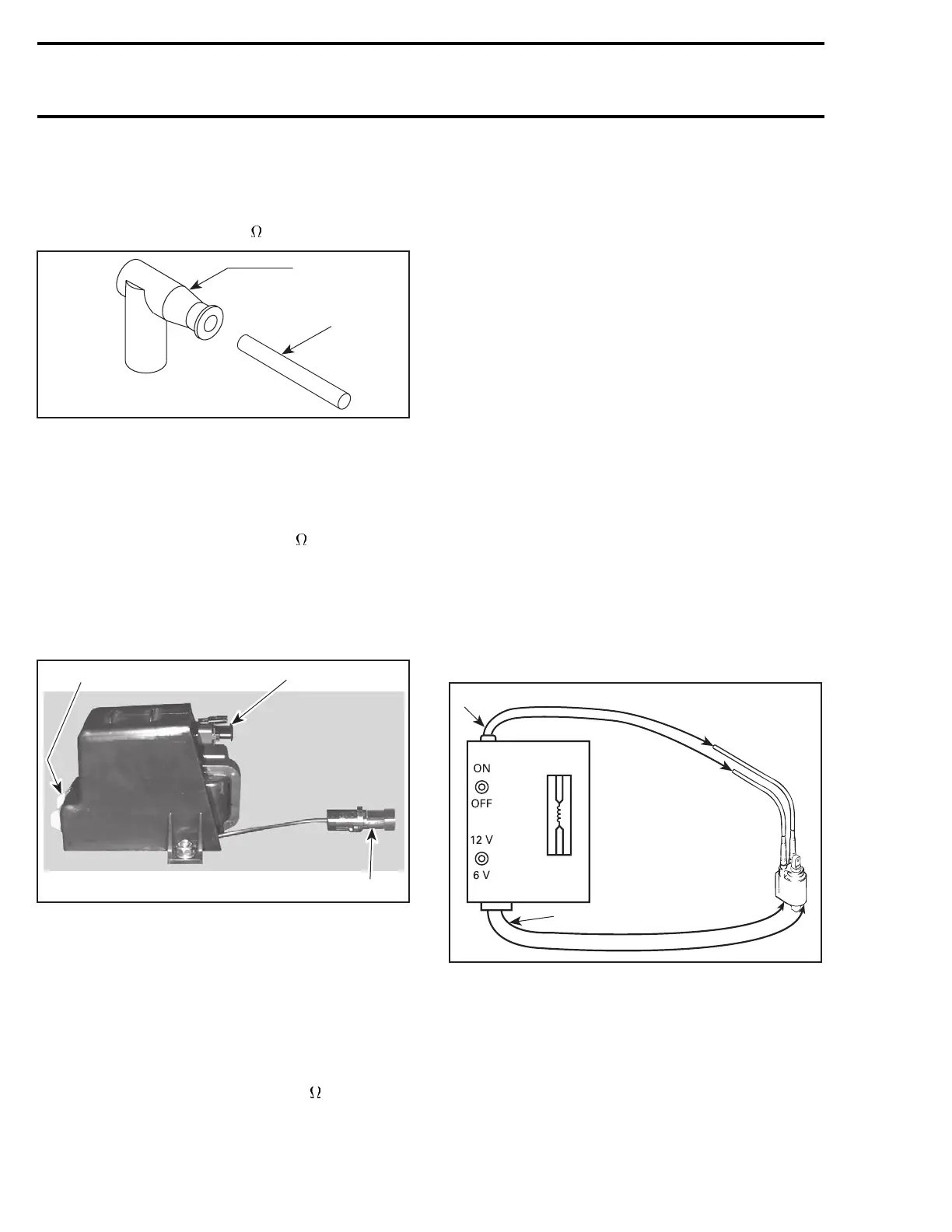

The spark plug caps must be removed from high

tension cables, because they are resistor caps.

The cap resistance is 4.48 k

.

A00E0QA

1

2

1. Resistor cap

2. High-tension cable

Using a multimeter, check the resistance between

the two high tension leads with the spark plug

caps removed.

Theresistanceshouldbe12±3k

at 20°C.

NOTE: A short circuit will read 0 ohm (or close to)

on ohmmeter.

787 RFI Engines

Primary Winding

F07H0EA

1

3

2

IGNITION COIL

1. Primary side

2. Secondary side

3. Ground wire

Disconnect the wire connector on the primary side

of the ignition coil.

Using a multimeter, check the resistance between

the terminals 1 and 2. Repeat a resistance test

between terminals 2 and 3.

The resistance should be 0.3 to 0.6

at 20°C.

If not within specification, replace the ignition coil.

If the ignition coil test good, check the power sup-

ply on the primary side.

Disconnect the ignition coil 3-pin connector.

Check to see if there is approximately 6 Vdc

between the red wire and engine ground.

If there is no voltage, either the MPEM or the

wiring harness is defective.

Secondary Winding

Due to the integrated diode, it is not possible

to take any resistance measurement of the sec-

ondary winding on the 787 RFI models.

DYNAMIC TEST

All Models

Use an ignition coil tester, available from

after-market tool/equipment suppliers.

CAUTION: Do NOT use coil tester on metal

work bench. Follow manufacturer instruc-

tions.

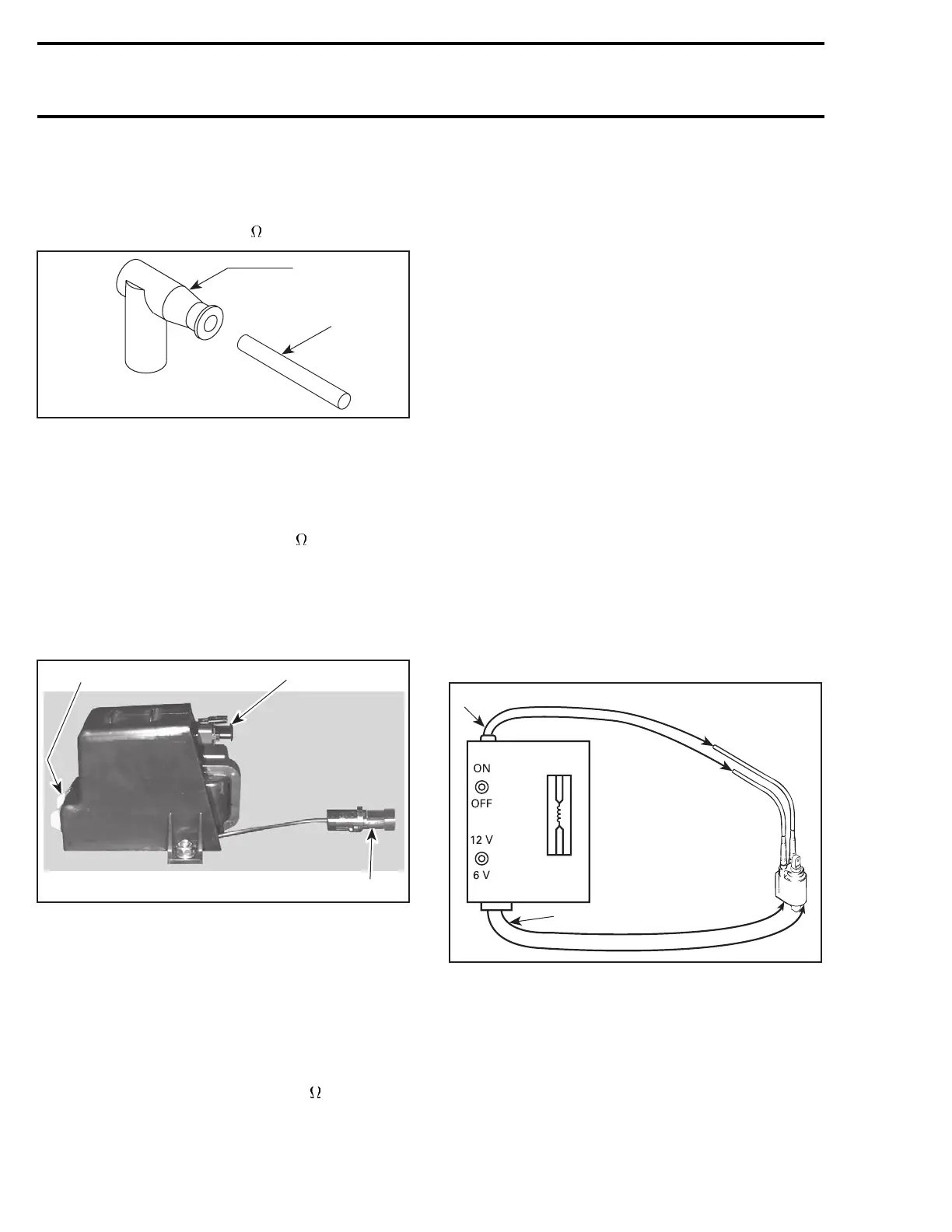

– With ignition coil removed from craft, discon-

nect spark plug caps from high tension cables.

– Hook high tension leads from tester to ignition

coil high tension cables.

– Connect2smallertesterleadstoprimaryof

ignition coil.

F00H14A

1

2

TYPICAL

1. Leads to secondary

2. Leads to primary

– Turnpowerswitchto12voltsandyoushould

observe spark jumping at a predetermined gap

of7to8mm(.276to.311in).

If there is no spark, if it is weak or intermittent, the

coil is defective and should be replaced.

554 smr2004-Complete Line Up

Loading...

Loading...