Section02MAINTENANCE

Subsection 03 (WATER-FLOODED ENGINE)

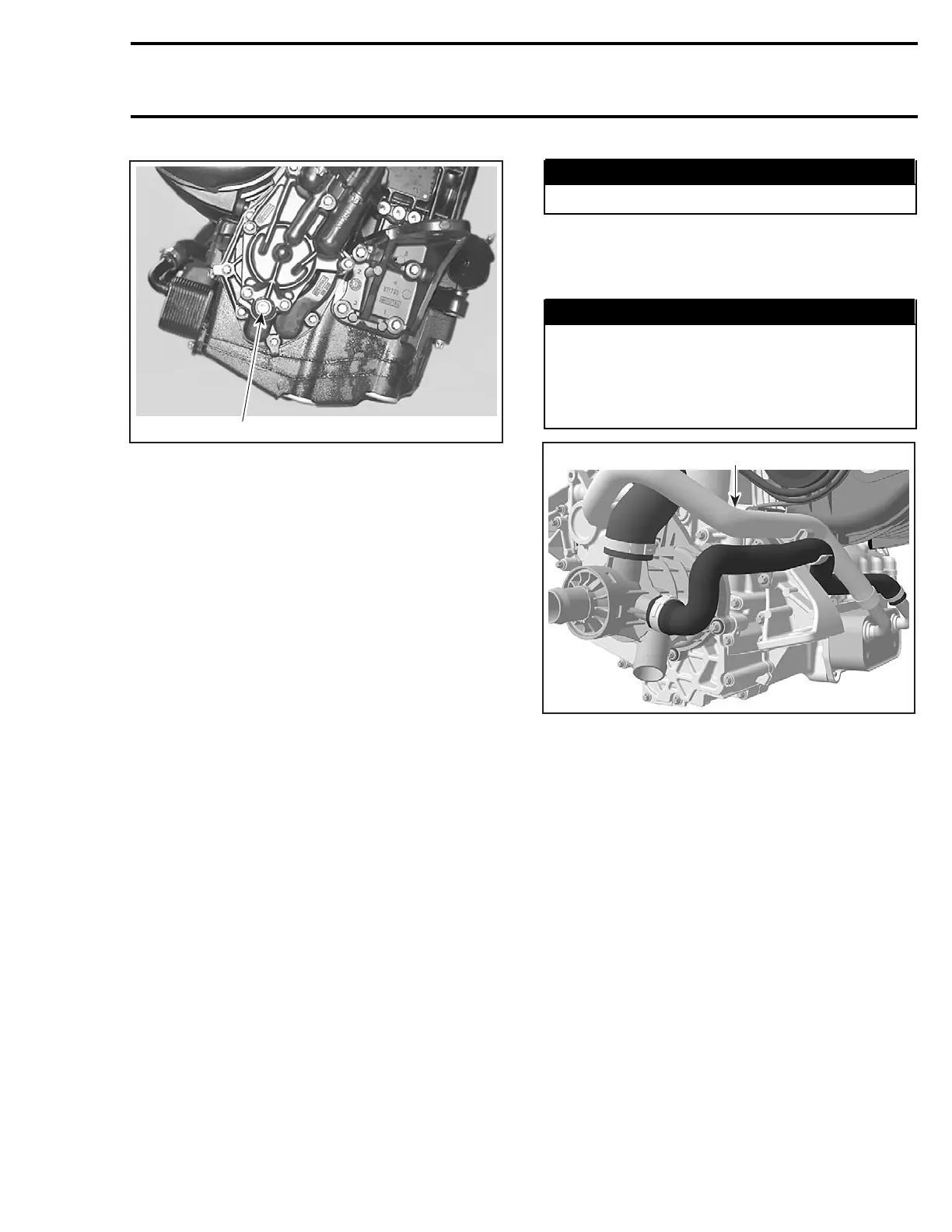

1

F18D19A

1. Scavenge oil pump cover drain plug

– Connect the oil vac tool Bombardier (P/N 529

035 880) to the fitting.

– Thefrontoftheenginemustbetilteddownap-

proximately 15 degrees to facilitate the removal

of the oil. Raise the rear of the boat according-

ly. Siphon the oil from the fitting.

– Level the engine.

– Remove the oil vac tool and the fitting. Apply

Loctite 243 and reinstall the drain plug.

NOTE: If spillage occurs, clean immediately with

the Pulley flange cleaner (P/N 413 711 809) to pre-

vent oil stains.

– Install a new oil filter and reinstall the oil filter

cap.

– Fill up the reservoir with fresh oil.

– Boil out the remaining water as follows:

• Recommended procedure: BOIL OUT PRO-

CEDURE IN A TEST TANK OR TIED TO A

TRAILER WITH WATERCRAFT IN WATER.

• Optional procedure: BOIL OUT PROCE-

DURE CONNECTED TO A FLUSH KIT.

Refer to instructions below.

Boil Out Procedure

NOTE: This procedure is intended to evaporate

the water contained in the oil.

Procedure in a Test Tank or Tied to a Trailer

with Watercraft in Water

– Run the engine for 5 minutes at 3500 RPM.

WARNING

Make sure to safely secure the watercraft.

– With the engine still running at 3500 RPM, in-

stall a hose pincher to the coolant line going to

the oil cooler.

WARNING

Certain components in the engine compart-

ment may be very hot. Direct contact may re-

sult in skin burn. Do not touch any electrical

parts or jet pump area when engine is run-

ning.

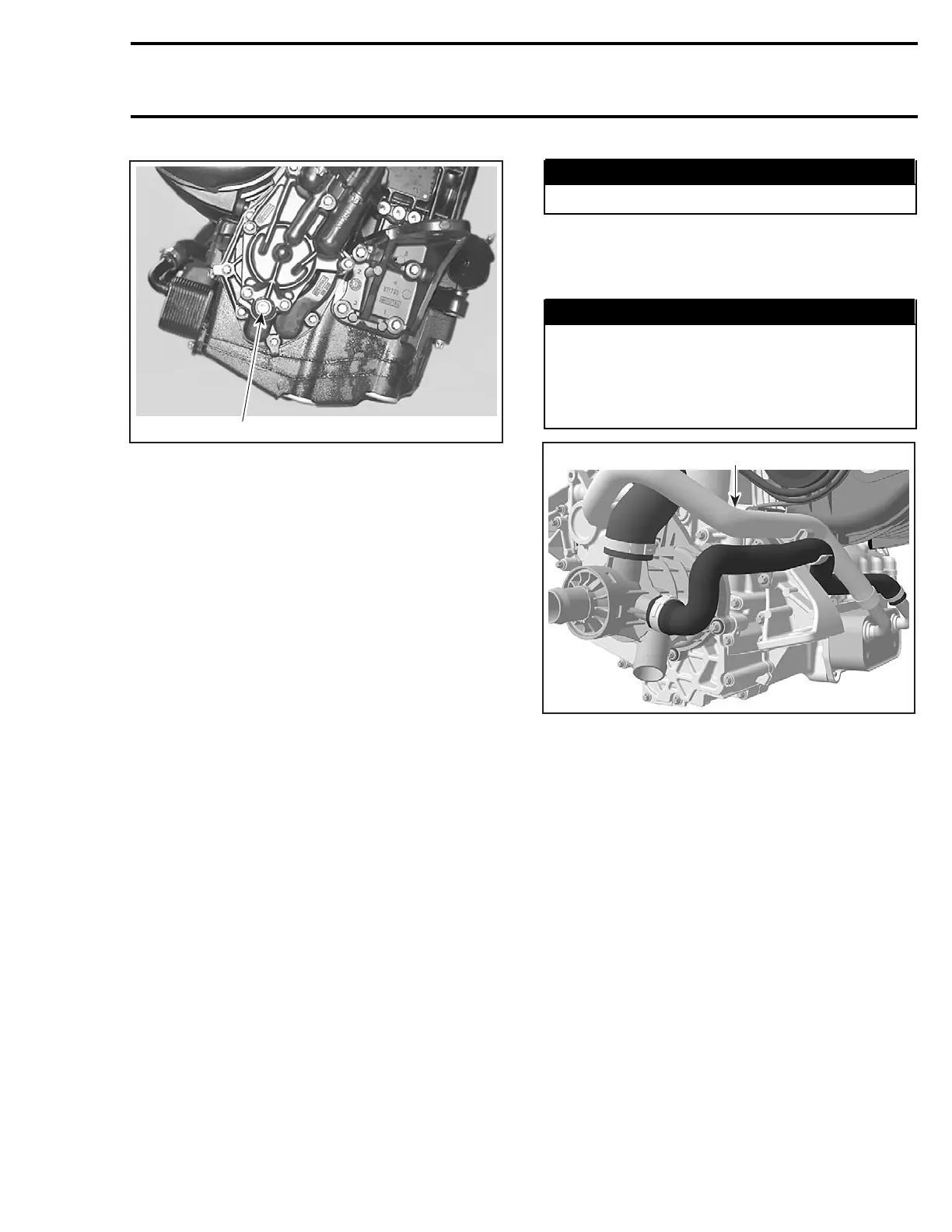

1

F18E1QA

1. Oil cooler coolant inlet hose

– Continue to run the engine at 3500 RPM for 15

more minutes (20 minutes total run time).

– Shuttheengineoff.

– Remove the hose pincher on the coolant line

going to the oil cooler.

CAUTION: Hose pincher must be removed pri-

or to operating the watercraft. Failure to do

this will result in damage to the engine.

– Change the oil and filter again.

– Procedure is now completed.

Procedure Connected to a Flush Kit

– On drive shaft, remove the C-clip then move

forward the ring seal carrier. Refer to D

RIVE

SYSTEM section.

CAUTION: Make sure that the ring seal carrier

is not in contact with the PTO seal assembly,

neither with the carbon ring.

– Connect a flush ki

t to the coolant line.

smr2004-Complete Line Up 37

Loading...

Loading...