TOMATECH AUTOMATION

9999999(IS_B)/0<Δk≤ 99999999(IS_C)(unit: least input increment, without sign

symbol)..

R(Δd):Axial (Z) tool retraction clearance after cutting to end point of radial cutting, its

range:0~99999999×least input increment(unit: mm/inch, without sign symbol).

The system defaults the tool retraction clearance is 0 after the radial cutting end point is

completed when R(Δd) is omitted.

The system defaults it executes the positive tool retraction when Z(W) and Q(Δk) are

omitted.

P

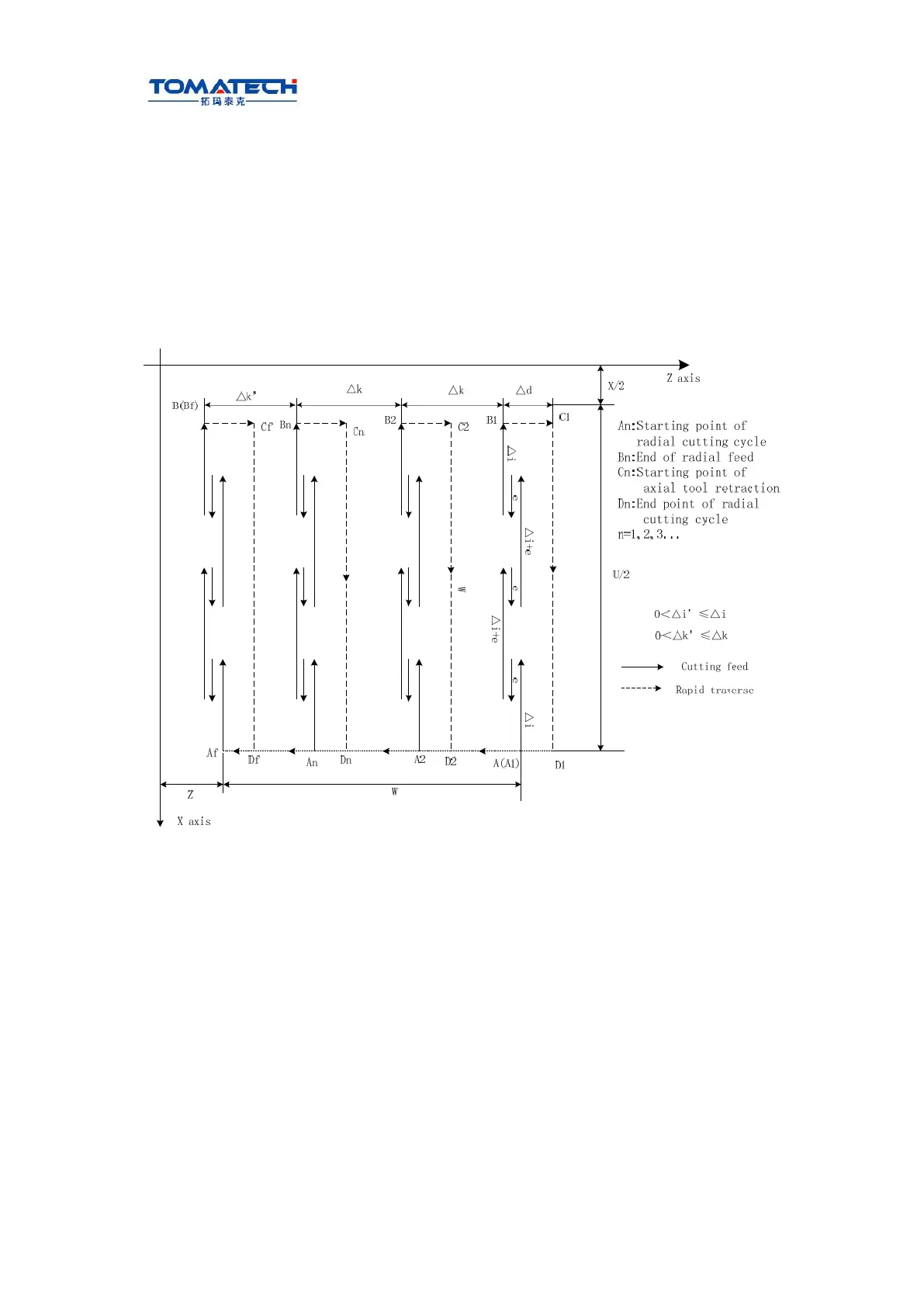

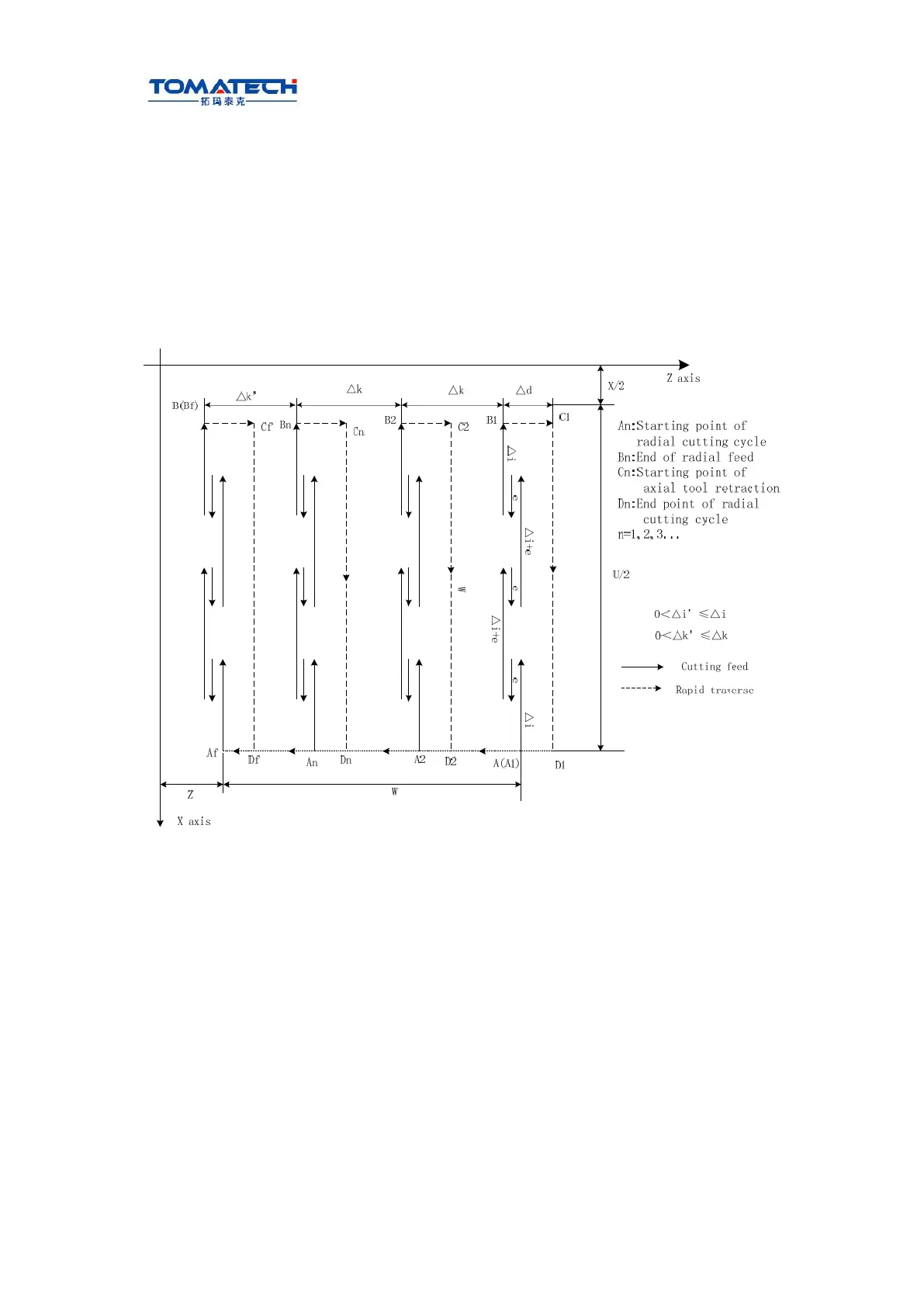

r Fig. 3-36 G75 path

Execution process: (Fig. 3-36)

① Radial (X) cutting feed △i from the starting point of radial cutting cycle, feed in X

negative direction when the coordinates of cutting end point is less than that of

starting point in X direction, otherwise, feed in X positive direction;

② Radial(X) rapid tool retraction e and its direction is opposite to the feed direction of ①;

③ X executes the cutting feed (Δk+e) again, the end point of cutting feed is still in it

between starting point An of radial cutting cycle and end point of radial tool infeed, X

executes the cutting feed (Δi+e) again and executes ②; after X cutting feed (Δi+e) is

executed again, the end point of X cutting feed is on Bn or is not on it between An and

Bn cutting feed to Bn and then execute○4 ;

④ Axial(Z) rapid tool retraction △d to Cn , when Z coordinate of Bf (cutting end point) is

less than that of A (starting point), retract tool in Z positive, otherwise, retract tool in Z

negative direction;

⑤ Radial (Z) rapid retract tool to Dn, No. n radial cutting cycle is completed. The current

Loading...

Loading...