TOMATECH AUTOMATION

radial cutting cycle is not the last one, execute ⑥; if it is the previous one before the

last radial cutting cycle, execute ⑦;

⑥ Axial(X) rapid tool infeed, and it direction is opposite to ④ retract tool. If the end point

of tool infeed is still on it between A and Af (starting point of last radial cutting cycle)

after Z tool infeed (△d+△k), i.e. Dn→An+1 and then execute ① (start the next radial

cutting cycle); if the end point of tool infeed is not on it between Dn and Af after Z tool

infeed (△d+△k), rapidly traverse to Af and execute ① to start the first radial cutting

cycle;

⑦ Z rapidly traverses to A, and G75 is completed.

Explanation:

● The cycle movement is executed by X(W) and P(Δi) blocks of G75, and the movement

is not executed if only “G75 R(e) ; ” block is executed;

● Δd and e are specified by the same address R and whether there are X(U) and P(Δi)

words or not in blocks to distinguish them;

● The tool can stop in Auto mode and traverse in Manual mode when G75 is executed,

but the tool must return to the position before executing in Manual mode when G75 is

executed again,otherwise the following path will be wrong;

● When the system is executing the feed hold or single block, the program pauses after

the system has executed end point of current path;

● R(Δd) must be omitted in grooving, and so there is no tool retraction clearance when

the tool cuts to radial cutting end point.

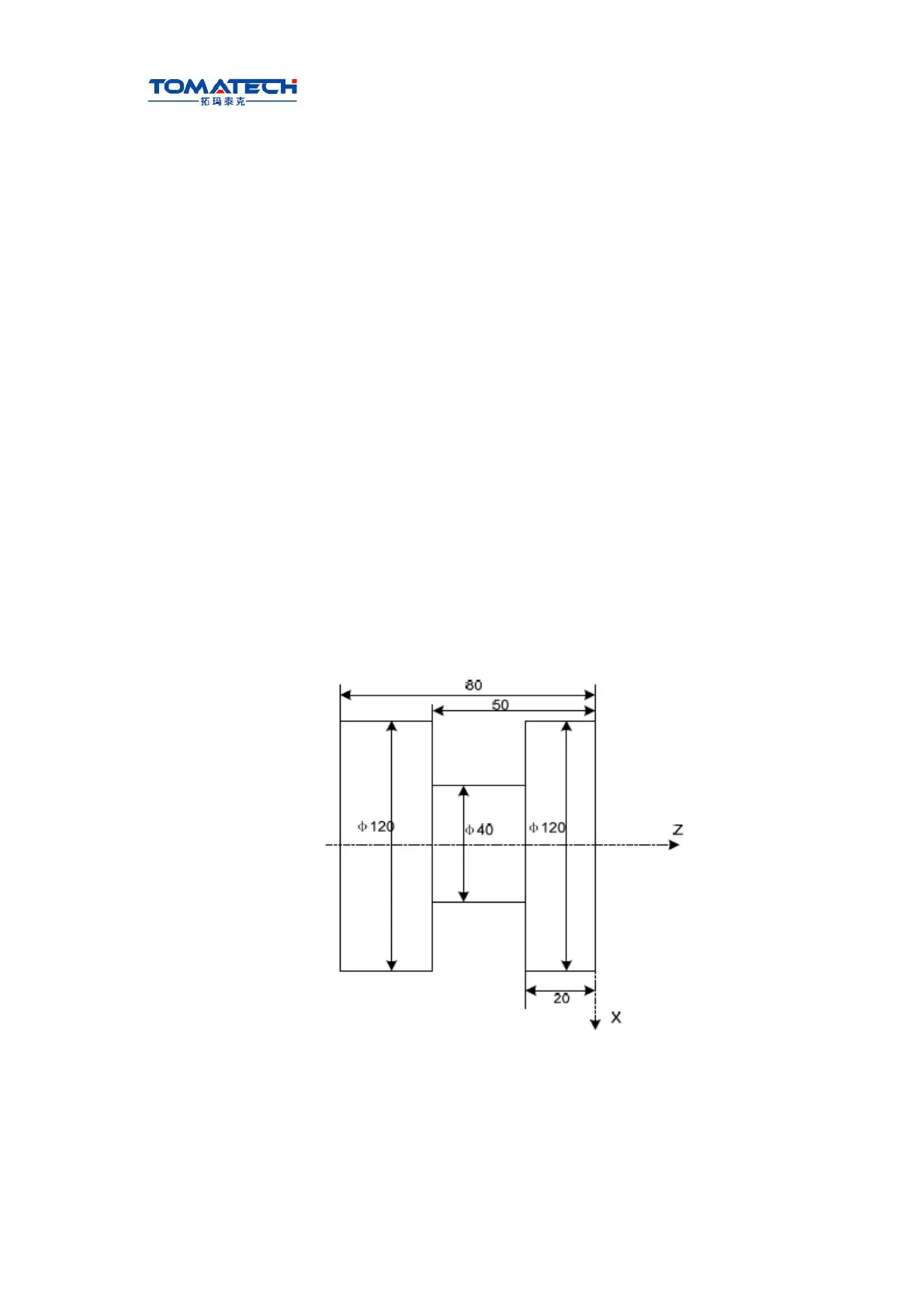

Example:Fig.3-37

Fig. 3-37 G75 cutting

Program (suppose the grooving tool width is 4mm, the system least increment is

0.001mm):

O0008;

G00 X150 Z50 M3 S500; (Start spindle with 500 r/min)

G0 X125 Z-20; (Position to starting point of machining)

Loading...

Loading...