TOMATECH AUTOMATION

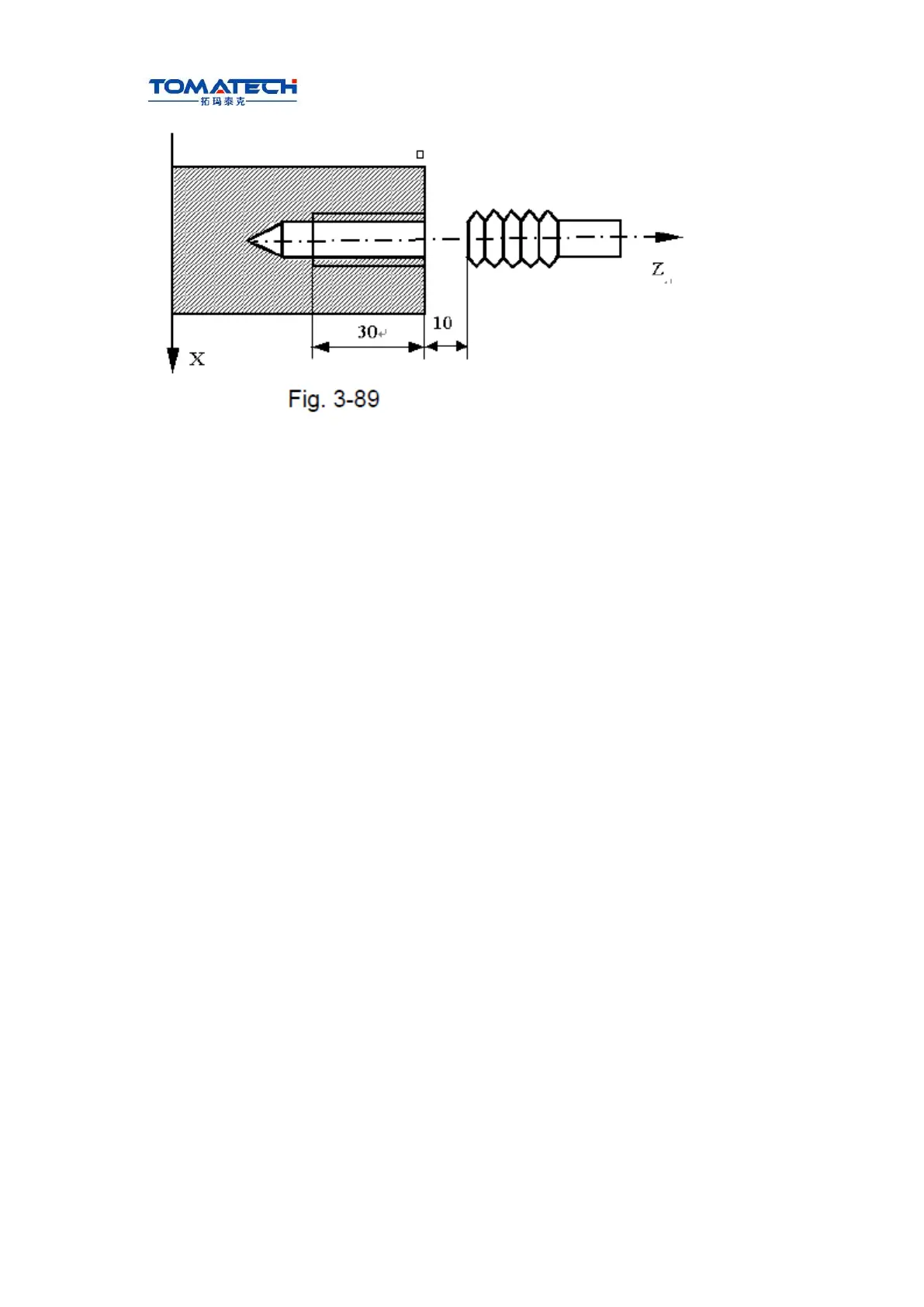

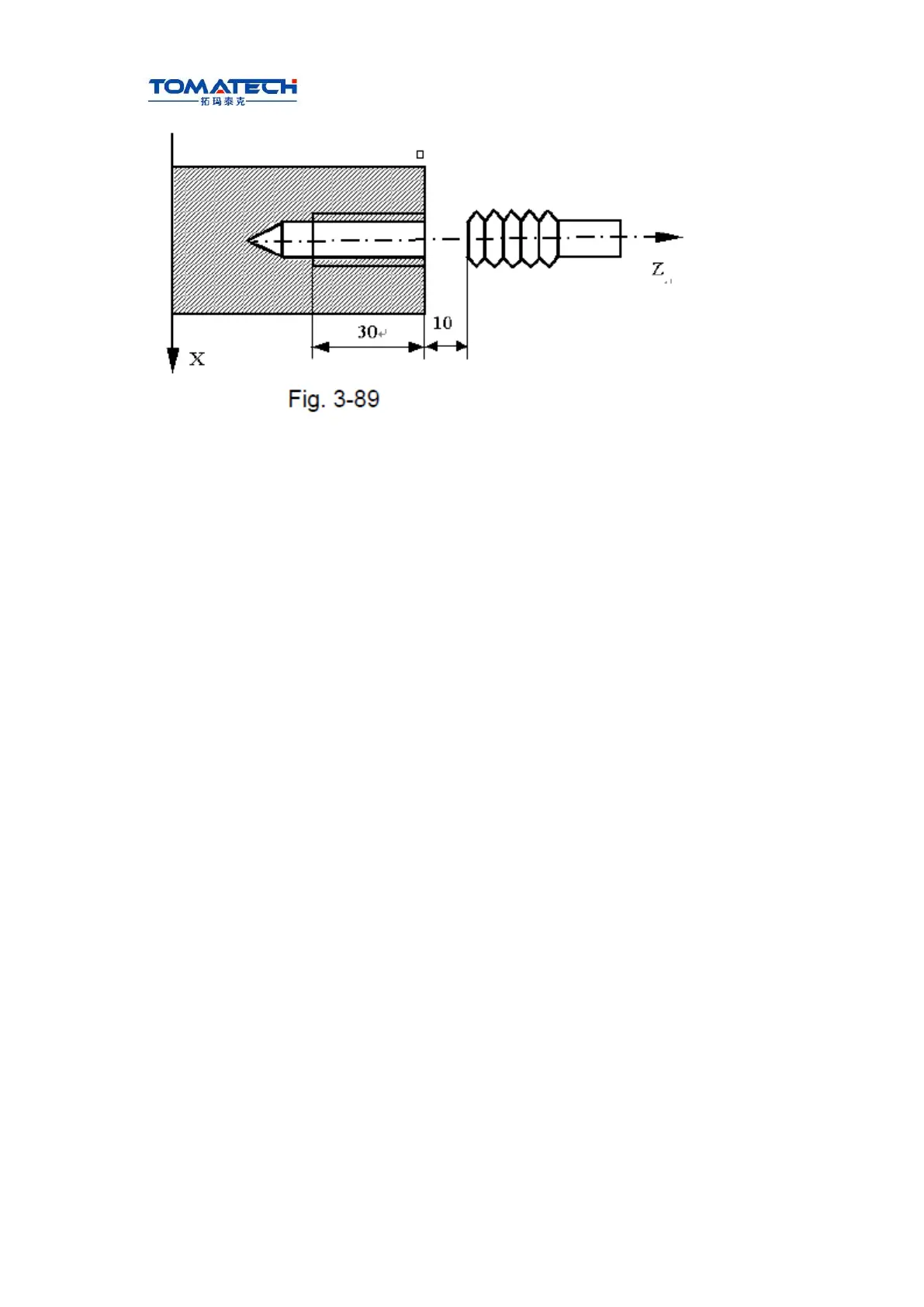

Example: Fig. 3-89, thread M10×1.5

Program:

O0011;

G00 Z90 X0 M03; Start spindle

G33 Z50 F1.5; Tap cycle

M03 Start spindle again

G00 X60 Z100; Machine continuously

M30

Note 1: Before tapping, define rotation direction of spindle according to tool rotating. The spindle

stops rotation after the tapping is completed and the spindle is started again when machining

thread continuously.

Note 2: G33 is for rigid tapping. The spindle decelerates to stop after its stop signal is valid, at the

moment, Z executes continuously infeeds along with the spindle rotating, and so the actual

cutting bottom hole is deeper than requirement and the length is defined by the spindle speed

and its brake in tapping.

Note 3: Z rapid traverse speed in tapping is defined by spindle speed and pitch is not relevant to

cutting feedrate override.

Note 4: In Single block to feed hold, the tapping cycle continuously executes not to stop until the

tool returns to starting point when the system displays “Pause”.

Note 5: The thread cutting decelerates to stop when the system resets, emergently stop or its

driver alarms.

3.21.5 Rigid tapping G84, G88

Command format:End face rigid tapping G84 X(U)__ C(H)__ Z(W)__ P__ F(I)__

K__M__;

Side rigid tapping G88 Z(W)__ C(H)__ X(U)__ P__ F(I)__ K__ M__;

Command explanations: modal G codes

G84: End face tapping cycle G code

G88: Side tapping cycle G code

(X,C): Tapping hole position;------G84

Z: Hole bottom position of tapping;------G84

(Z,C):Tapping hole position;------G88

X: Hole bottom position of tapping hole;------G88

Loading...

Loading...