TOMATECH AUTOMATION

P: Pause time (ms) when tapping to the hole bottom

F(I):Thread lead, F(I)> 0 right-hand tapping, F(I)< 0 left-hand tapping

K: Repetitive count of tapping. When the incremental programming is used to the tapping

hole position, the tapping is performed in the different hole position

M: Used to clamp the graduation spindle.

Rigid tapping method:

� M29 S_ before G84/G88 is specified below

M29 S_;

G84(G88) X_C_(Z_C_) Z_(X_) P_ F_ K_ M_;

� M29 S_ in the same block is commanded below

G84(G88) X_C_(Z_C_) Z_(X_) R_ P_ F_ K_ M29 S_;

Notes :

1) For the above 2nd method, the machine zero return is executed before the spindle executes the

tapping, otherwise, the method cannot be used. In M29, CNC cannot select a spindle to execute

the tapping. The rigid tapping needs to be clamped when the spindle positioning is completed,

the method also cannot be used because M codes cannot be in the same block;

2) The axis movement command cannot be use between M29 and G84/G88;

3) M29 cannot be specified repetitively in rigid tapping;

4) In multiple spindle rigiding tapping, a spindle used to the rigid tapping must be selected before

M29, and it cannot be switched before the rigid tapping state is cancelled;

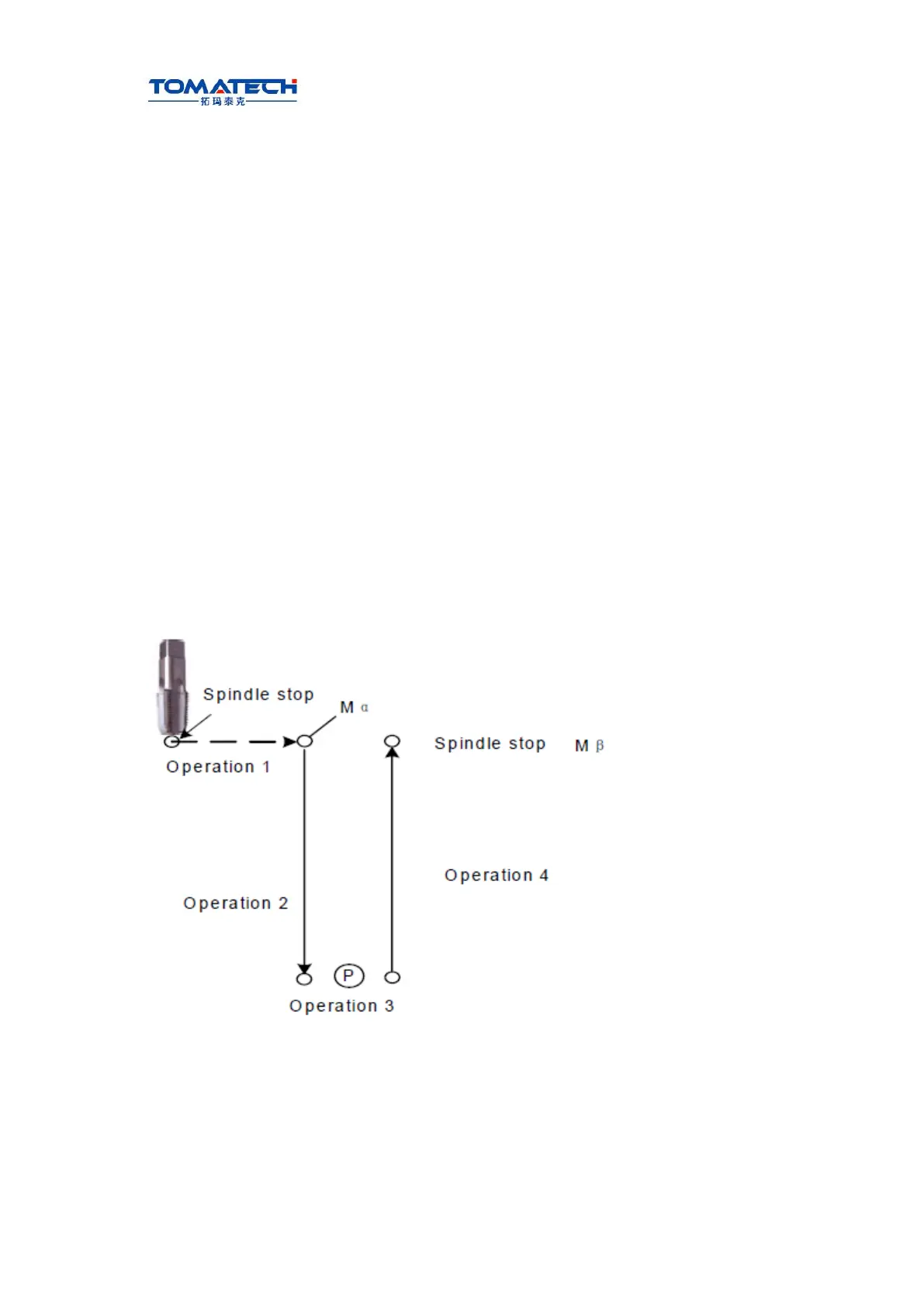

Operations is shown below:

Execution

explanations:

� Operation 1:positioning to the hole position(starting point of rigid tapping);

� Before starting operation 2, the system outputs Mα when it has M code used to clamp

the spindle;

� Operation 2:start the rigid tapping;

� Operation 3:pause time P in rigid tapping in hole bottom;

� Operation 4:the rigid tapping returns to the hole bottom(starting point of rigid tapping;

Loading...

Loading...