TOMATECH AUTOMATION

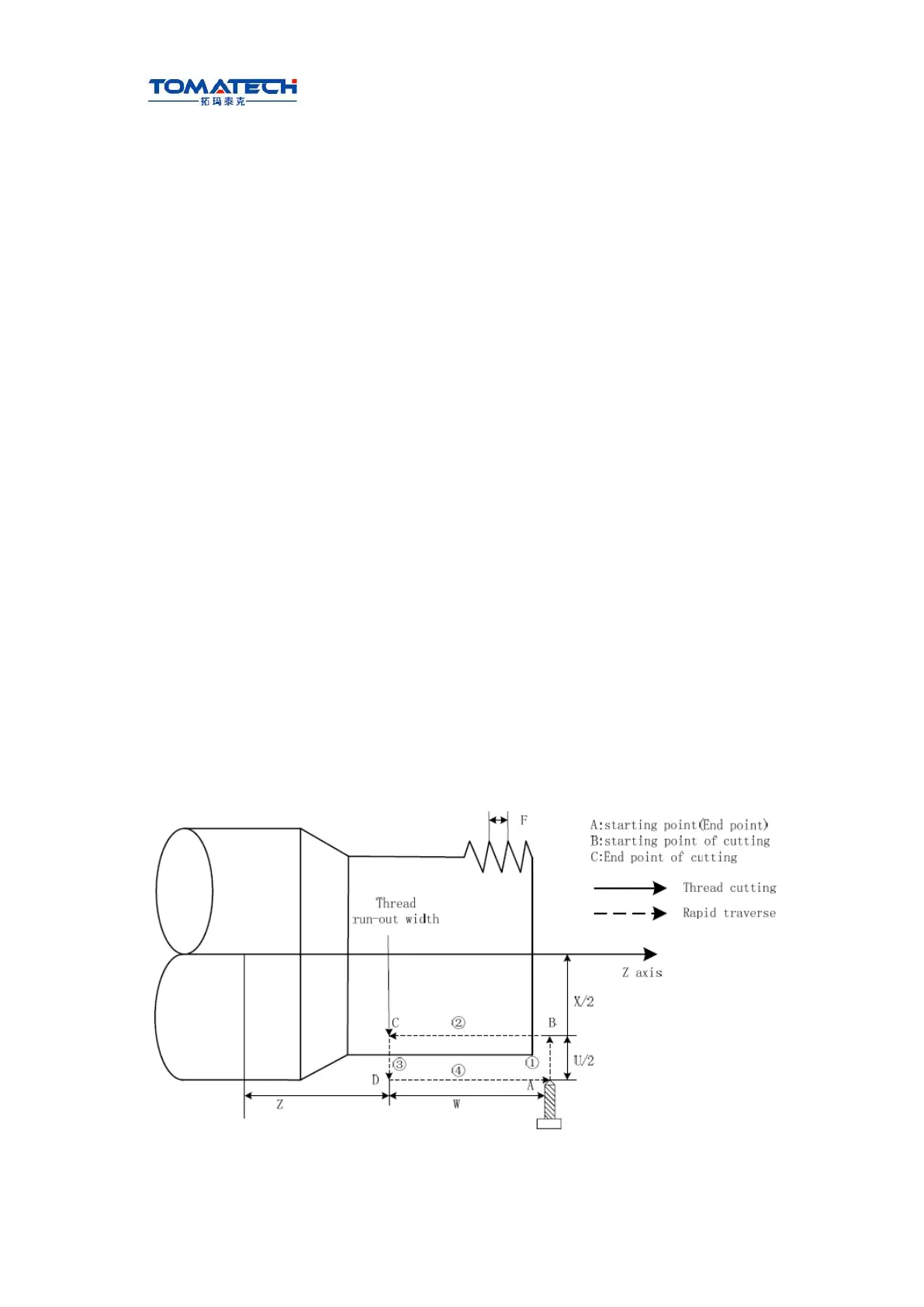

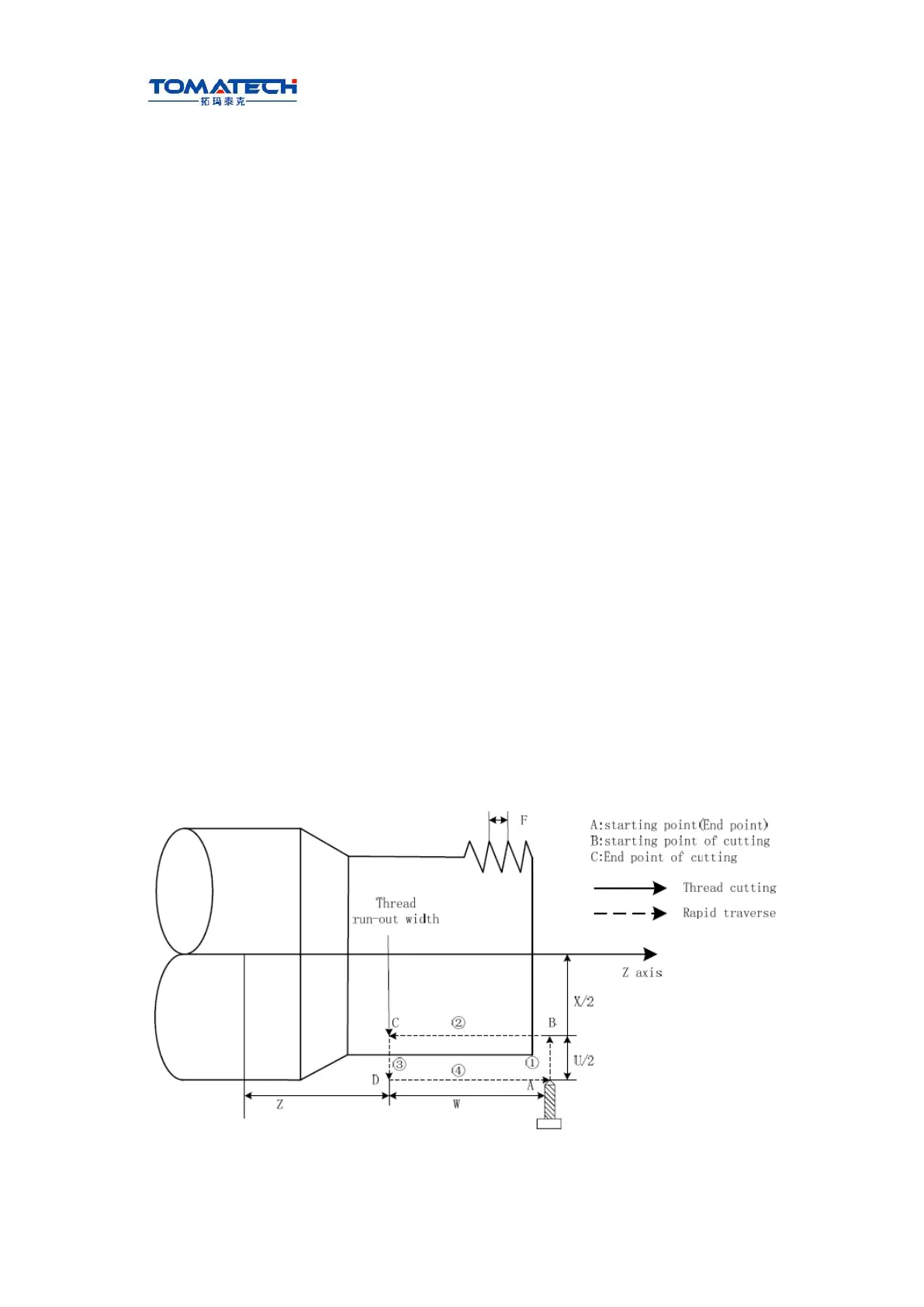

Z reaches to end point of cutting as Fig. 3-44.

Command specifications:

G92 is modal;

Starting point of cutting: starting position of thread interpolation;

End point of cutting: end position of thread interpolation;

X: X absolute coordinate of end point of cutting, unit: mm;

U: different value of X absolute coordinate from end point to starting point of cutting, unit:

mm;

Z: Z absolute coordinate of end point of cutting, unit: mm;

W: Different value of X absolute coordinate from end point to starting point of cutting, unit:

mm;

R: Different value(radius value) of X absolute coordinate from end point to starting point of

cutting.When the sign of R is not the same that of U, R│≤│U/2│, unit: mm;

F: Thread lead, its range: 0< F ≤500 mm. After F value is executed, it is reserved and

can be omitted;

I: Thread teeth per inch, its range: 0.06tooth/inch~25400tooth/inch , it is reserved and it

can be omitted not to input after I specified value is executed;

J: Movement in the short axis in thread run-out, its range 0~99999999× least input

increment , unit: mm/inch, without direction ( automatically define its direction according to

starting position of program), and it is modal parameter. If the short axis is X, its value is

specified by radius;

K: Movement in the long axis in thread run-out, its range: 0~99999999× least input

increment ,

unit: mm/inch, without direction ( automatically define its direction according to starting

position of program), and it is modal parameter. If the long axis is X, its value is specified

by radius;

L: Multi threads: 1~99 and it is modal parameter. (The system defaults it is single thread

when L is omitted).

Fig. 3-44

Loading...

Loading...