TOMATECH AUTOMATION

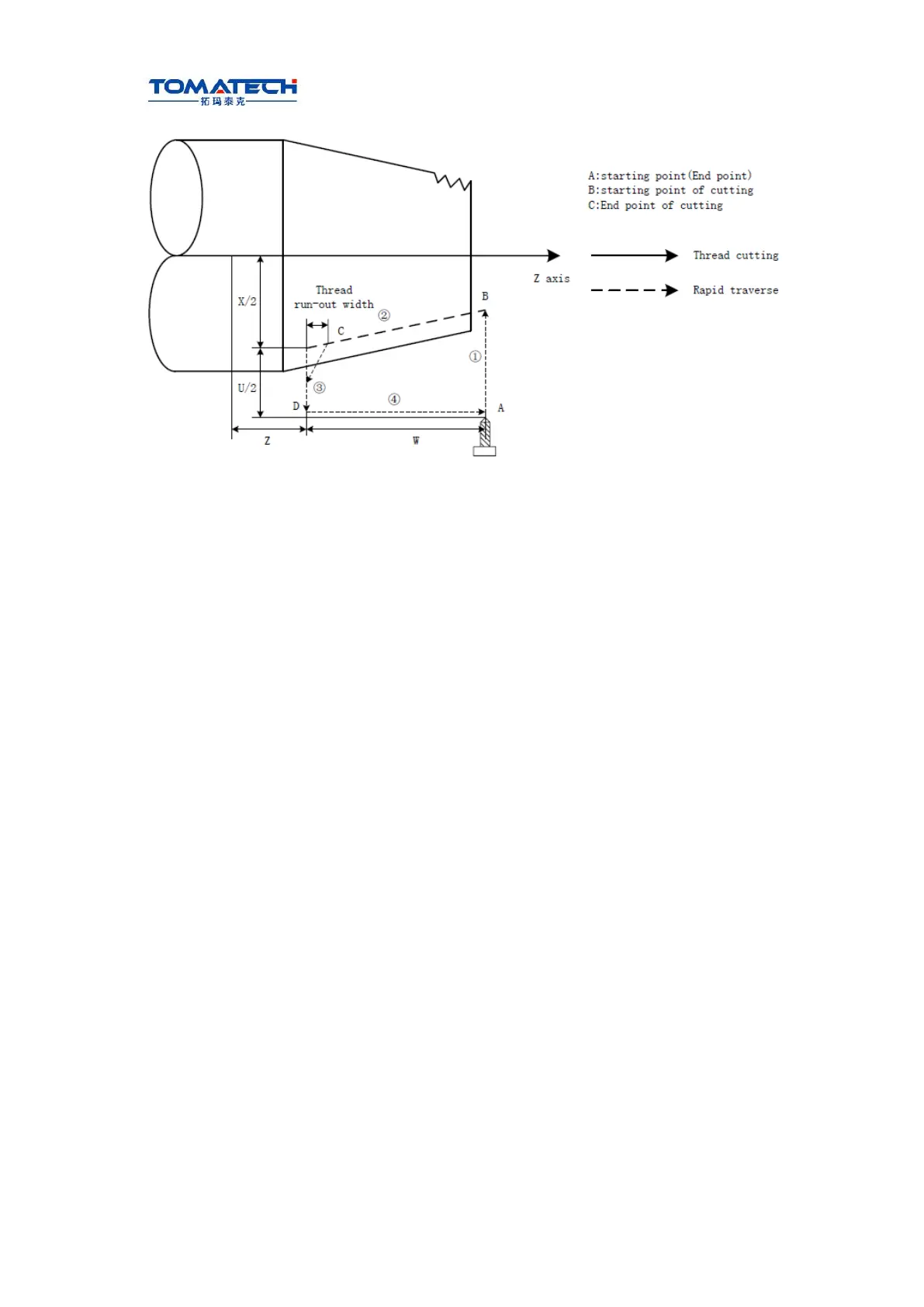

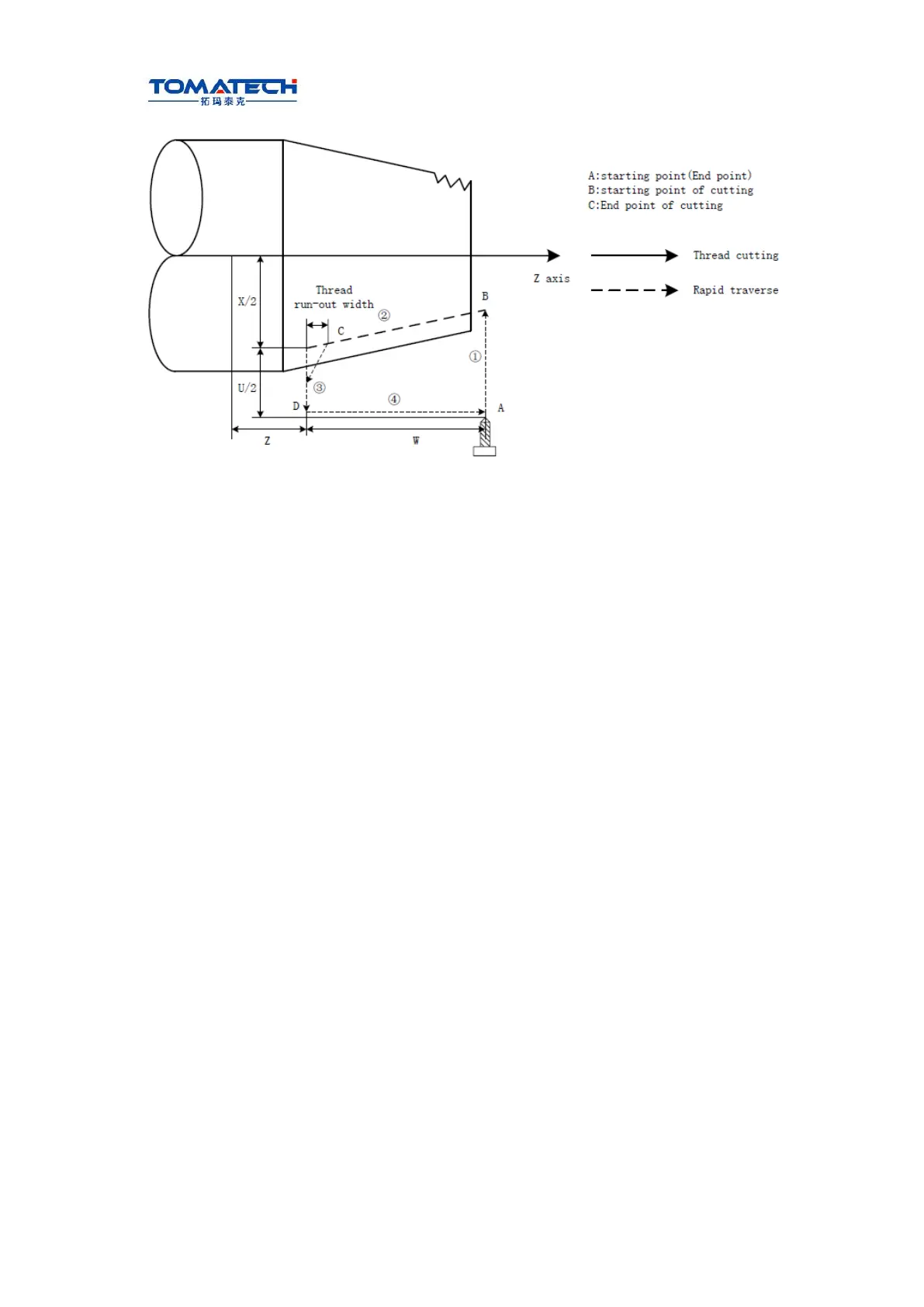

Fig. 3-45

The system can machine one thread with many tool infeed in G92, but cannot do

continuous two thread and end face thread. Definition of thread pitch in G92 is the same

that of G32, and a pitch is defined that it is a moving distance of long axis(X in radius)

when the spindle rotates one rev.

Pitch of taper thread is defined that it is a moving distance of long axis(X in radius). When

absolute value of Z coordinate difference between B point and C point is more than that of

X (in radius), Z is long axis; and vice versa.

Cycle process: straight thread as Fig.3-44 and taper thread as Fig.3-45.

① X traverses from starting point to cutting starting point;

② Thread interpolates (linear interpolation) from the cutting starting point to cutting end

point;

③ X retracts the tool at the cutting feedrate (opposite direction to the above-mentioned

), and return to the position which X absolute coordinate and the starting point are

the same;

④ Z rapidly traverses to return to the starting point and the cycle is completed.

Programming

Notes:

● Length of thread run-out is specified by №019 when J, K are omitted;

● Length of thread run-out is K in the long direction and is specified by №019 when J is

omitted;

● Length of thread run-out is J=K when K is omitted;

● There is no thread run-out when J=0 or J=0, K=0;

● Length of thread run-out is J=K when J≠0,K=0;

● There is no thread run-out when J=0,K≠0;

● After executing the feed hold in thread cutting, the system does not stop cutting until

the thread cutting is completed with Pause on screen;

● After executing single block in thread cutting, the program run stops after the system

returns to starting point(one thread cutting cycle is completed);

● They are executed as the positive values when J, K negative values are input;

Loading...

Loading...