TOMATECH AUTOMATION

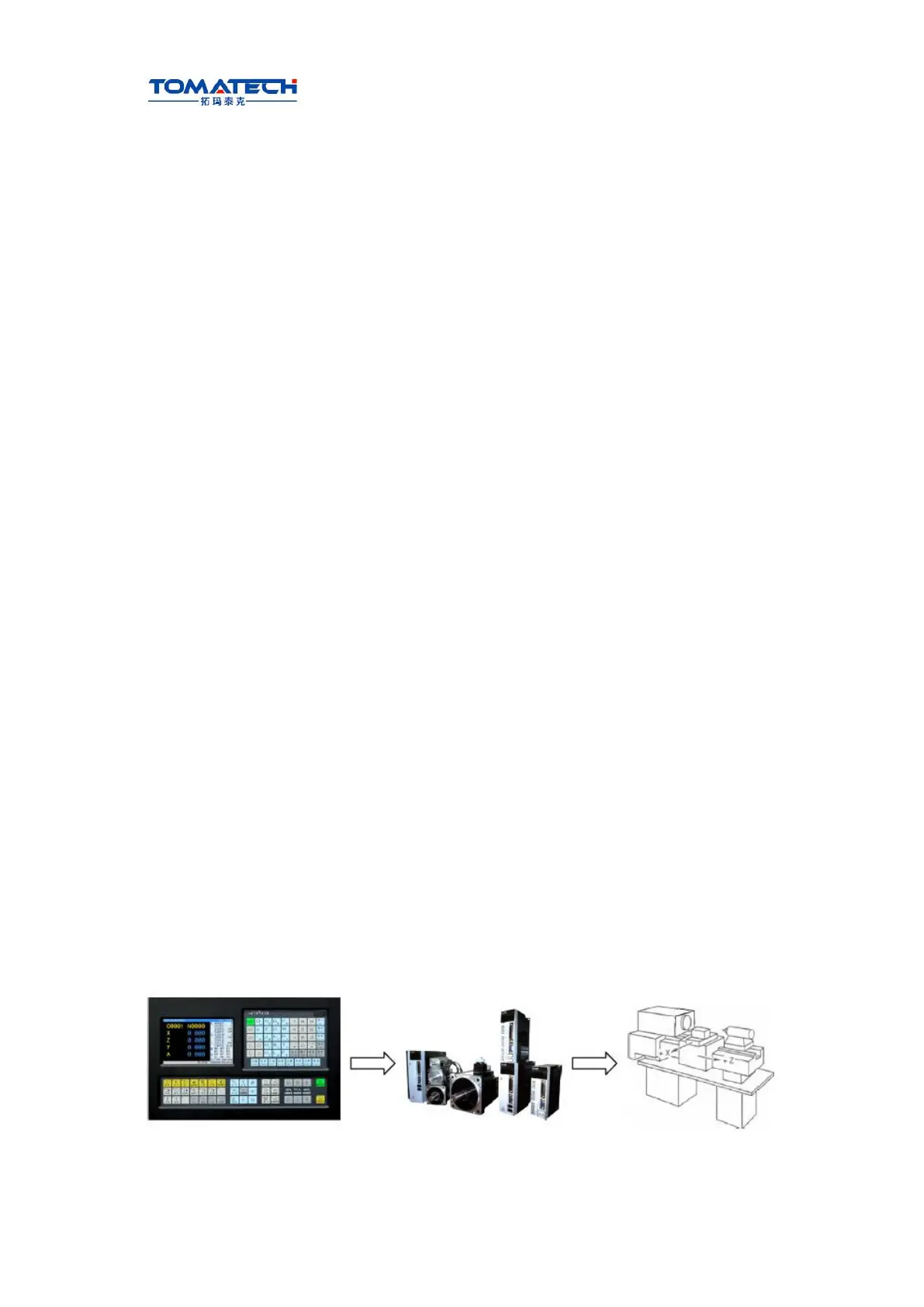

1.2 CNC System and CNC Machine

CNC machine tool is an electro-mechanical integrated product, composed of Numerical

Control Systems of Machine Tools, machines, electric control components, hydraulic

components, pneumatic components, lubricant, cooling and other subsystems

(components), and CNC systems of machine tools are control cores of CNC machine

tools. CNC systems of machine tools are made up of computerized numerical

control(CNC), servo (stepper) motor drive devices, servo (or stepper) motor etc.

Operational principles of CNC machine tools: according to requirements of machining

technology, edit user programs and input them to CNC, then CNC outputs motion control

commands to the servo (stepper) motor drive devices, and last the servo (or stepper)

motor completes the cutting feed of machine tool by mechanical driving device; logic

control commands in user programs to control spindle start/stop, tool selections, cooling

ON/OFF, lubricant ON/OFF are output to electric control systems of machine tools from

CNC, and then the electric control systems control output components including buttons,

switches, indicators, relays, contactors and so on. Presently, the electric control systems

are employed with Programmable Logic Controller (PLC) with characteristics of compact,

convenience and high reliance. Thereof, the motion control systems and logic control

systems are the main of CNC machine tools.

TAC-100XT Turning Machine CNC system has simultaneously motion control and logic

control function to control two axes of CNC machine tool to move, and has nested PLC

function. Edit PLC programs (ladder diagram) according to requirements of input and

output control of machine tool and then download them toTAC-1002T Turning Machine

CNC system, which realizes the required electric control requirements of machine tool, is

convenient to electric design of machine tool and reduces cost of CNC machine tool.

Software used to controlTAC-1002T Turning Machine CNC system is divided into system

software (NC for short) and PLC software (PLC for short). NC system is used to control

the display, communication, edit, decoding, interpolation and acceleration/deceleration,

and PLC system for controlling explanations, executions, inputs and outputs of ladder

diagrams. Standard PLC programs are loaded (except for the special order)

whenTAC-1002T Turning Machine CNC System is delivered, concerned PLC control

functions in following functions and operations are described according to control logics of

standard PLC programs, marking with “Standard PLC functions” in . Refer to Operation

Manual of machine manufacturer about functions and operations of PLC control because

the machine manufacturer may modify or edit PLC programs again.

Ⅰ Programming

Fig. 1-1

Loading...

Loading...