TOMATECH AUTOMATION

rotational speed control is valid and the spindle speed is defined (r/min). G96 is

modal G code. If the current modal is G97, G97 cannot be input.

Command format: G50 S__; (S0000~S9999, the leading zero can be omitted.)

Command function: define max. spindle speed limit (r/min) in the constant surface speed

control and take the current position as the program reference point.

G96, G97 are the modal word in the same group but one of them is valid. G97 is the initial

word and the system defaults G97 is valid when the system is switched on.

When the machine tool is turning it, the workpiece rotates based on the axes of spindle as

the center line, the cutting point of tool cutting workpiece is a circle motion around the

axes, and the instantaneous speed in the circle tangent direction is called cutting surface

(for short surface speed). There are different surface speed for the different workpiece

and tool with different material.

When the spindle speed controlled by the analog voltage is valid, the constant surface

control is valid. The spindle speed is changed along with the absolute value of X absolute

coordinates of programming path in the constant speed control. If the absolute value of X

absolute coordinates adds, the spindle speed reduces, and vice verse, which make the

cutting surface speed as S command value. The constant speed control to cut the

workpiece makes sure all smooth finish on the surface of workpiece with diameter

changing.

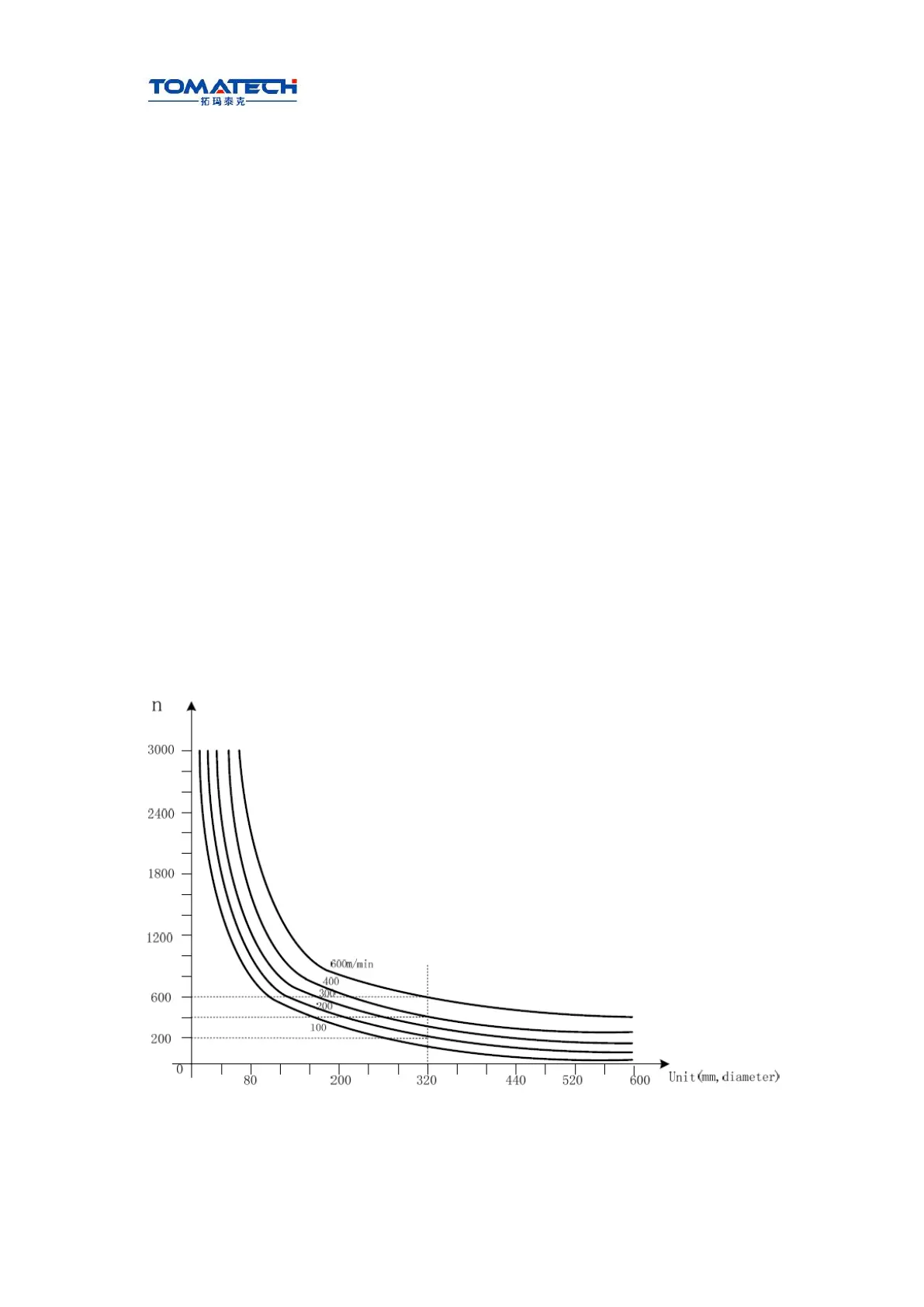

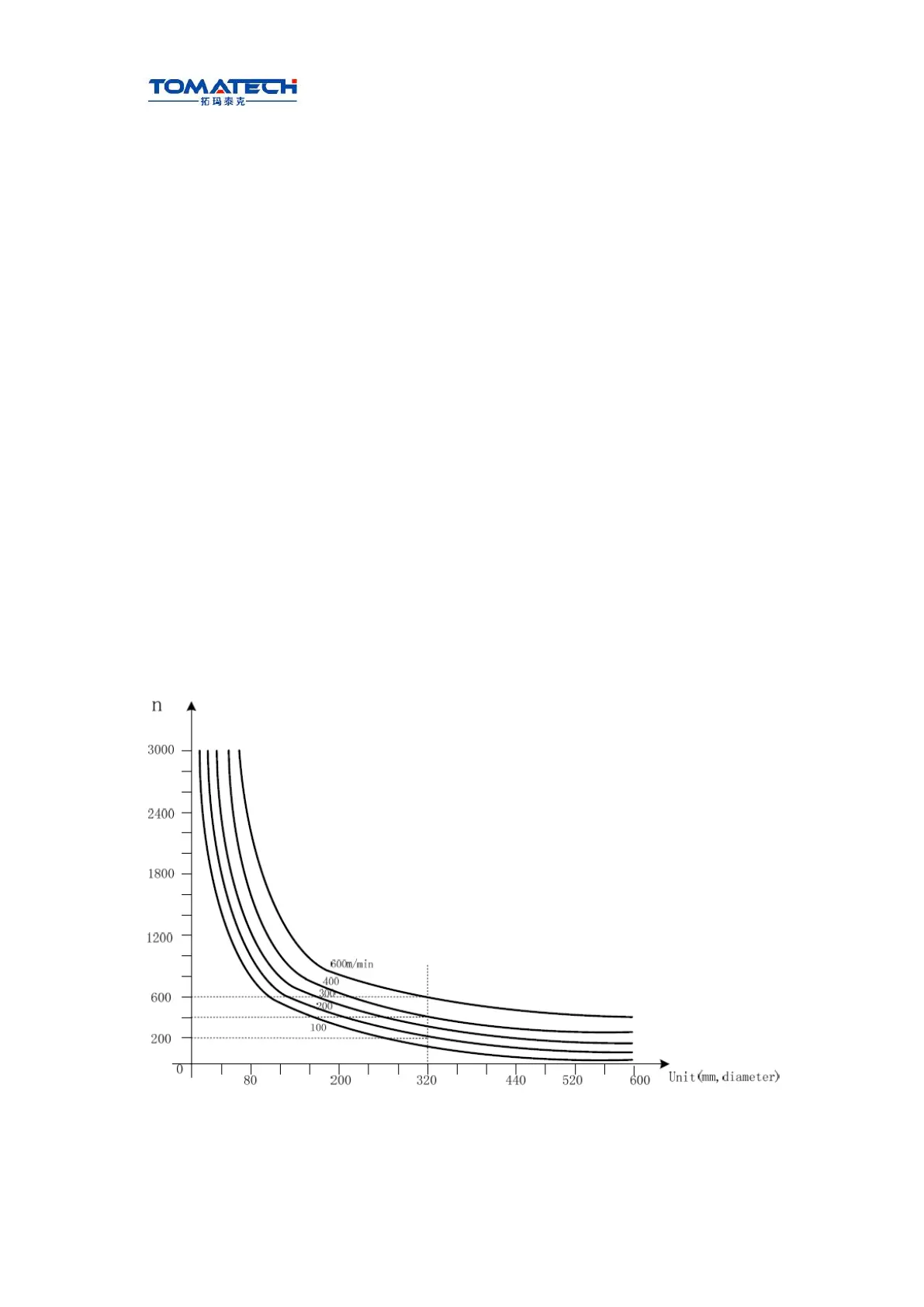

Surface speed=spindle speed × |X| × π ÷1000 (m/min)

Spindle speed: r/min

|X|: absolute value of X absolute coordinate value, mm

π ≈3.14

Fig. 2-4

In G96, the spindle speed is changed along with the absolute value of X absolute

coordinates value of programming path in cutting feed (interpolation), but it is not changed

in G00 because there is no actual cutting and is counted based on the surface speed of

Loading...

Loading...