TOMATECH AUTOMATION

end point in the program block.

In G96 (constant surface speed control), Z coordinates axis of workpiece system must

consist with the axes of spindle (rotary axis of workpiece), otherwise, there is different

between the actual surface speed and the defined one.

G96 control is valid, G50 S_ can limit max. spindle speed (r/min). The spindle actual

speed is the limit value of max. speed when the spindle speed counted by the surface

speed and X coordinates value is more than the max. spindle speed set by G50 S_. After

the system powers on, max. spindle speed limit value is not defined and its function is

invalid. Max. spindle speed limit value defined by G50 S_ is reserved before it is defined

again and its function is valid in G96. Max. spindle speed defined by G50 S_ is invalid in

G97 but its limit value is reserved.

Note: When NO.043 (lowest spindle speed in constant surface speed control) is set to 0 and G50

S0 is executed, the spindle speed is limited to 0 r/min (the spindle does not rotate).

When the constant surface speed is controlled by the system parameter No.043, the

spindle speed is lower limit, which is higher than one counted by the surface speed and X

axis coordinates value.

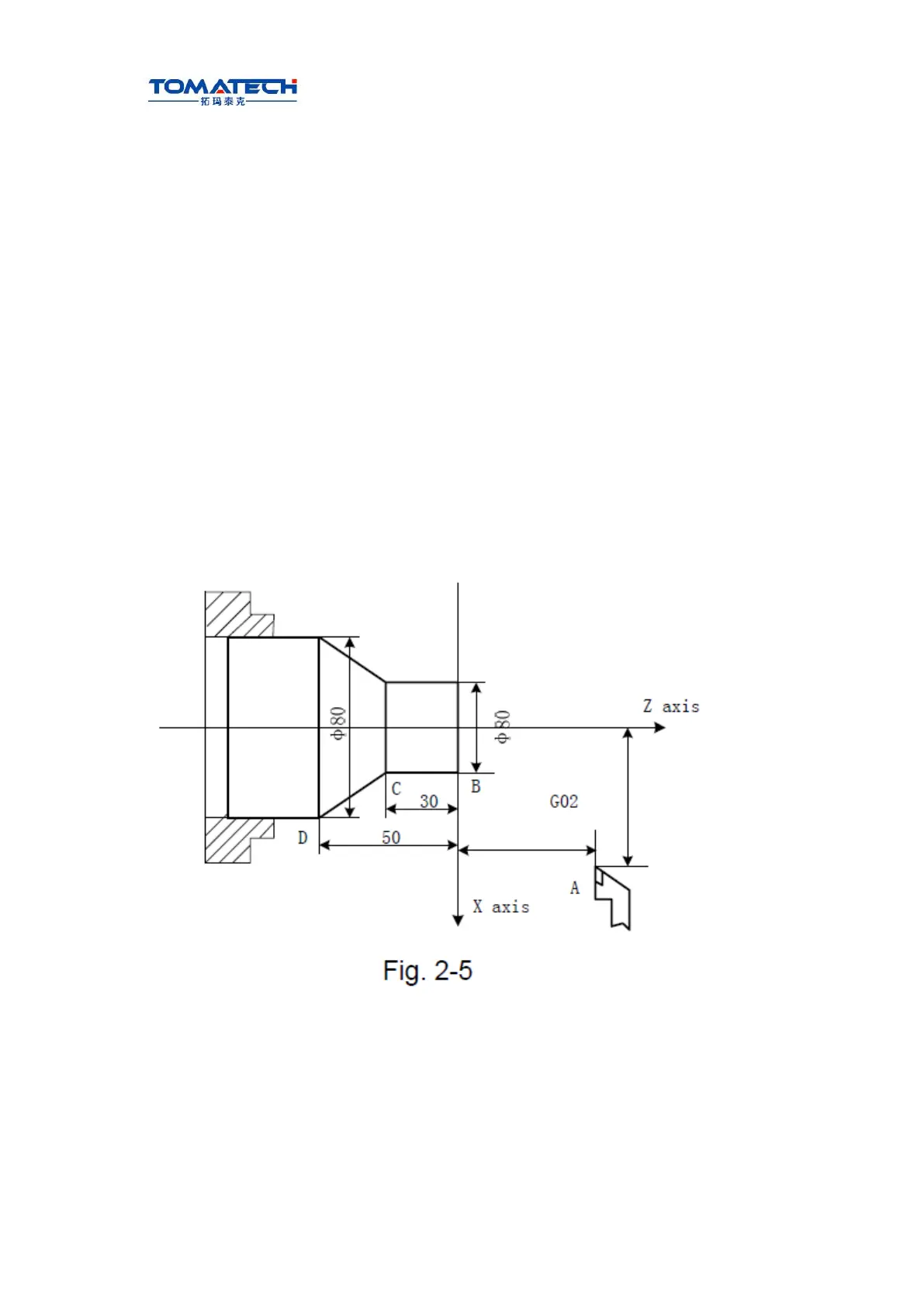

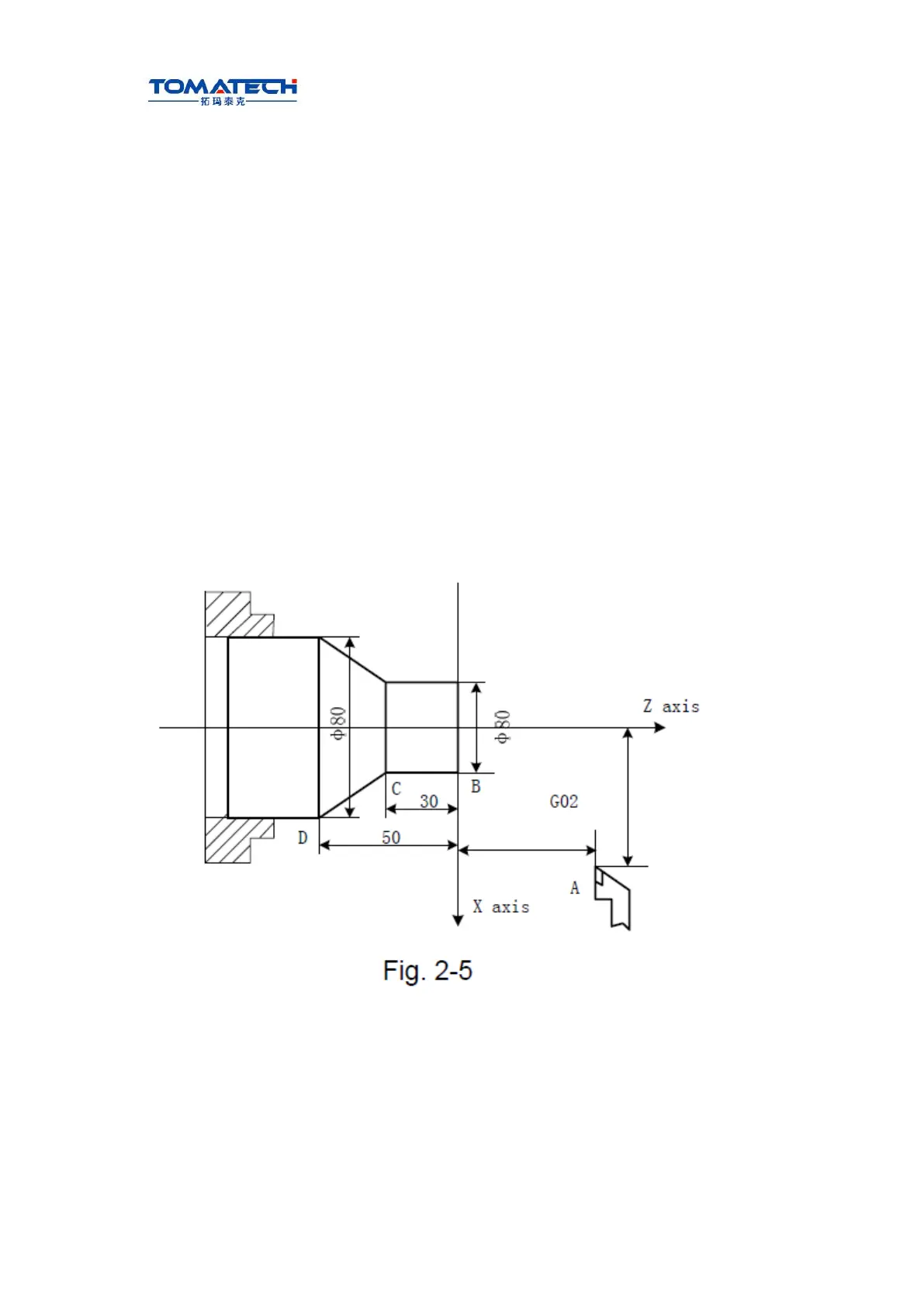

Example:

O0001 ; (Program name)

N0010 M3 G96 S300; (Spindle rotates clockwise, the constant surface speed control is

valid and the surface speed is 300 m/min)

N0020 G0 X100 Z100; (Rapid traverse to A point with spindle speed 955 r/min)

N0030 G0 X50 Z0; (Rapid traverse to B point with spindle speed 1910 r/min)

N0040 G1 W-30 F200; (Cut from B to C with spindle speed 1910 r/min)

N0050 X80 W-20 F150; (Cut from C to D with spindle speed 1910 r/min and surface

speed 1194 r/min)

Loading...

Loading...