TOMATECH AUTOMATION

G30 Pn X(U) Z(W) X and Z return to the machine nth reference point simultaneously

Note 1: n in the above table is 2, 3 or 4;

Note 2: Do not check the deceleration, zero signal when you execute the machine 2nd, 3rd, 4th

reference point.

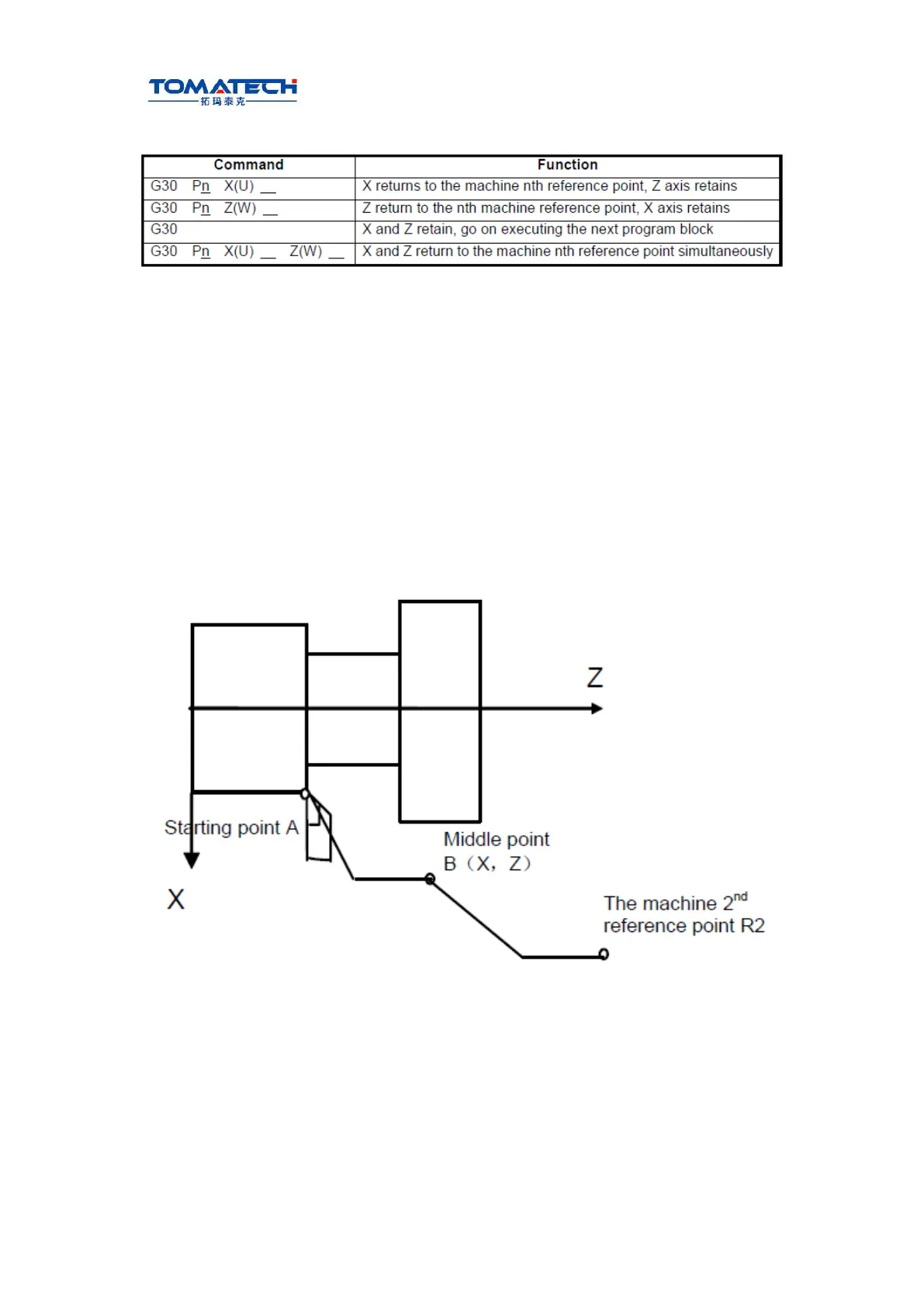

Command operations: (taking example of returning to machine 2nd reference point as

follows):

(1) Rapidly traverse to the middle position of command axis from the current position (A

point

→B point);

(2) Traverse from the middle point with the speed set by No.113 to the 2nd reference point

set by

No.122 and No.123 (B point →R2 point);

(3) When CNC is not in the machine lock state, the completion signal of reference point

return ZP21 Bit0, Bit1 is high.

Note 1: Execute the machine 2nd, 3rd, 4th reference point return after you manually execute the

machine reference point return or G28 (machine reference point return).

Note 2: A→B and B0→R2, two axes separately traverse, and so their trails are linear or not.

Note 3: CNC cancels the tool length compensation after you execute G30 to return 2nd, 3rd, and

4

th

reference point.

Note 4: Must not execute G30 (machine 2nd, 3rd, 4th reference point return) when the zero switch

is not installed on the machine.

Note 5: Do not set the workpiece coordinate system when you execute the 2nd, 3rd, and the

machine 4

th

reference point return.

Loading...

Loading...