TOMATECH AUTOMATION

system is created again (using G50).

Command specifications:

G50 is non-modal;

X: New absolute coordinates of current position in X direction;

U: Different value between the new absolute coordinates of current position in X direction

And the absolute coordinates before executing commands;

Z: New absolute coordinates of current position in Z direction;

W: Different value between the new absolute coordinates of current position in X direction

and the absolute coordinates before executing commands;

In G50, when X(U) or Z(W) are not input, the system does not change current coordinates

position as program zero; when X(U) and Z(W) are not input, the system takes the

previous setting position as program zero.

Example:

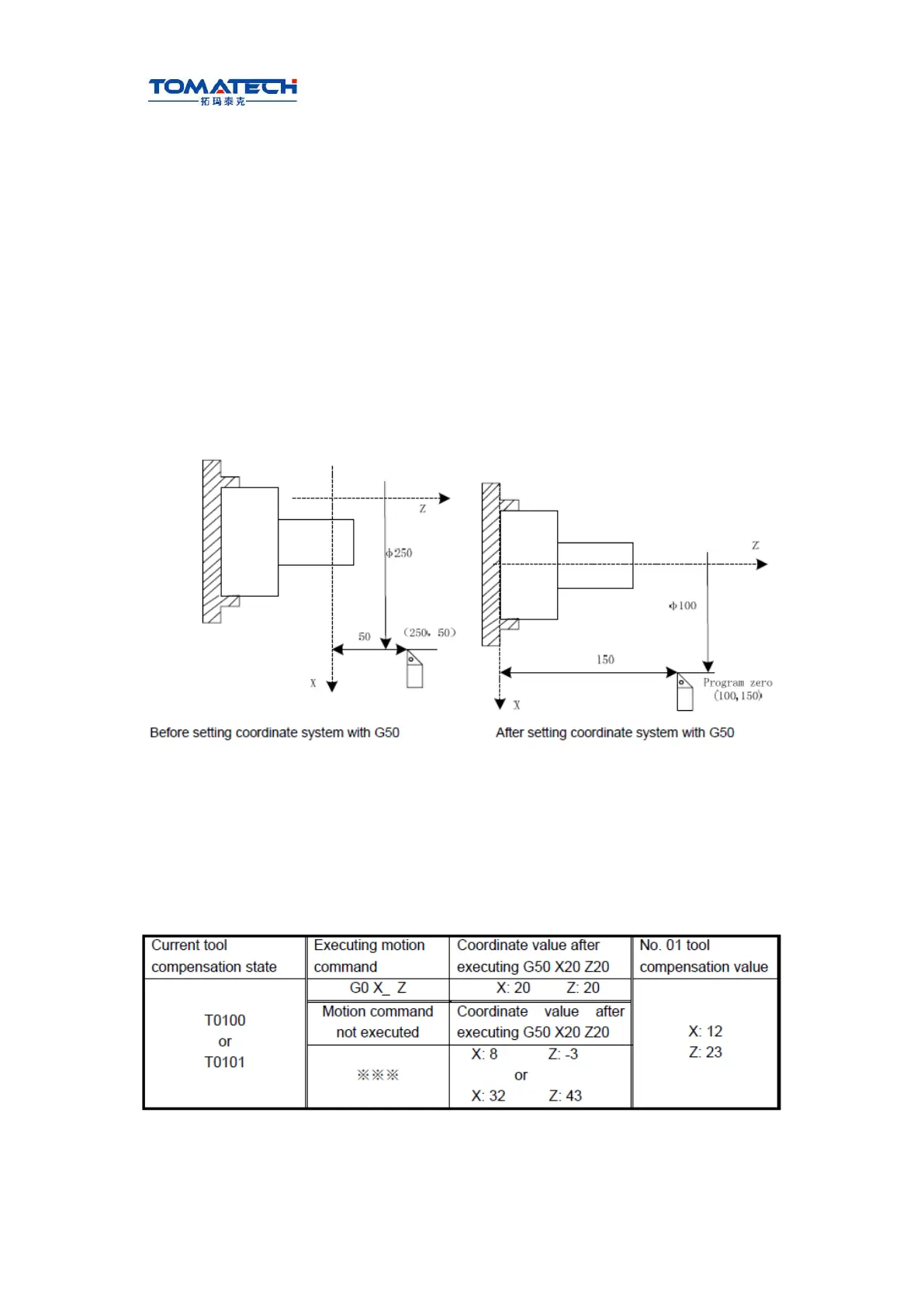

Ⅰ Programming Fig.3-16

As Fig.3-16, create the above-mentioned workpiece coordinate system and set (X100

Z150) to the reference point of program after executing “G50 X100 Z150”.

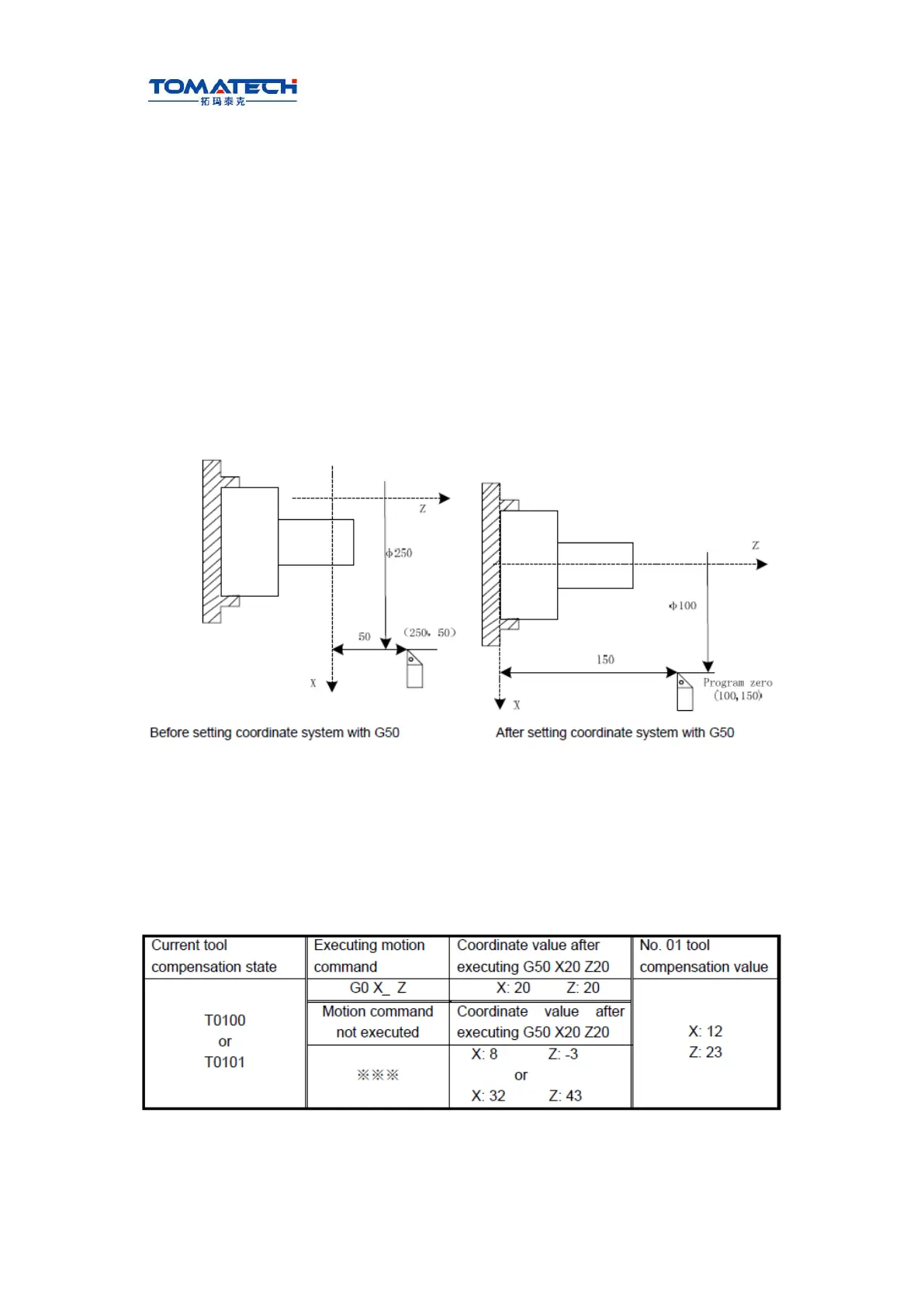

Note: When No.003 Bit4 is 1(executing tool compensation by coordinates offset), T function is

executed,motion command is not executed and the system creates workpiece coordinate system

with G50, the displayed coordinate value are ones which are defined by G50 adding or

subtracting tool compensation value which is not executed.

Loading...

Loading...