TOMATECH AUTOMATION

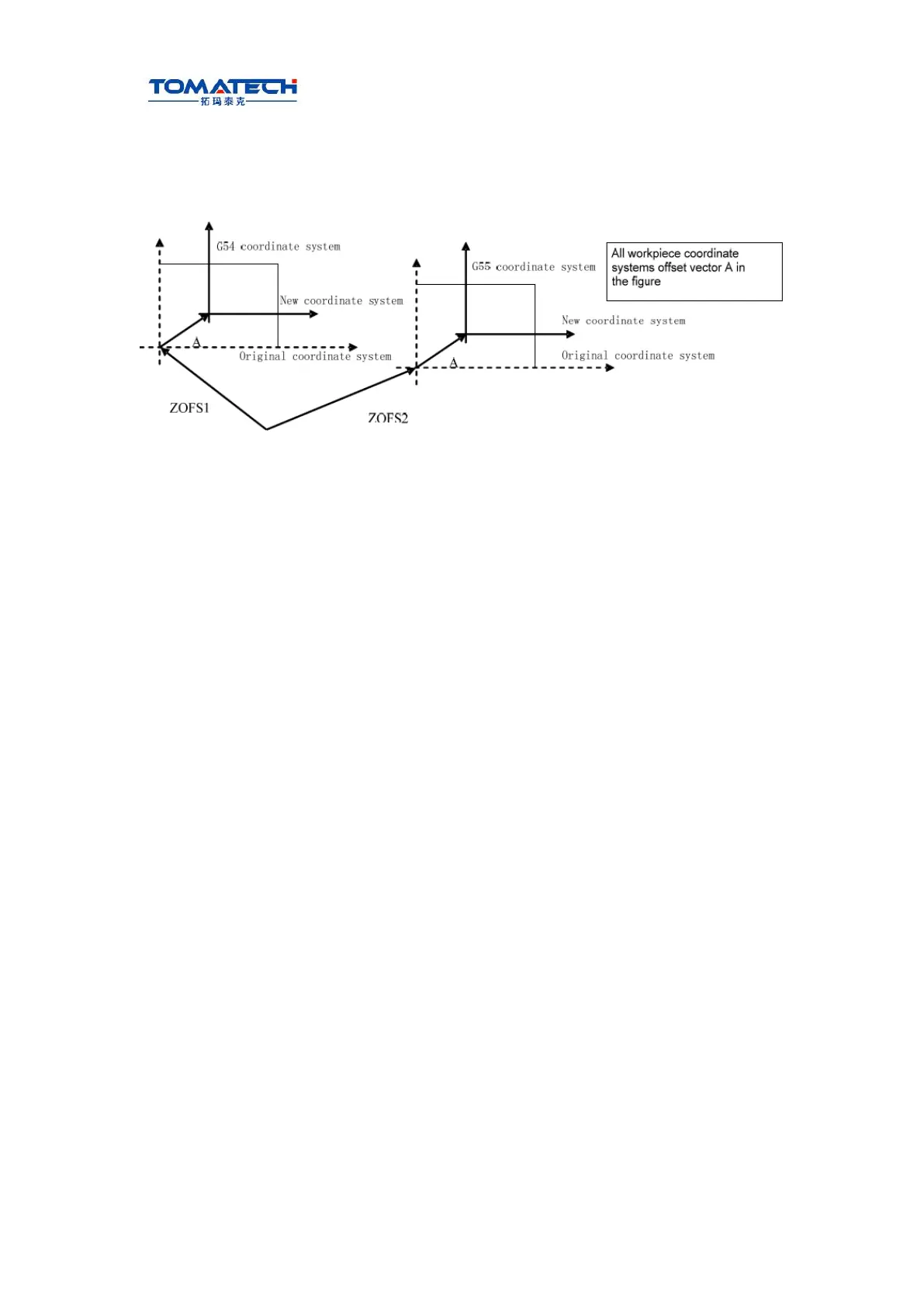

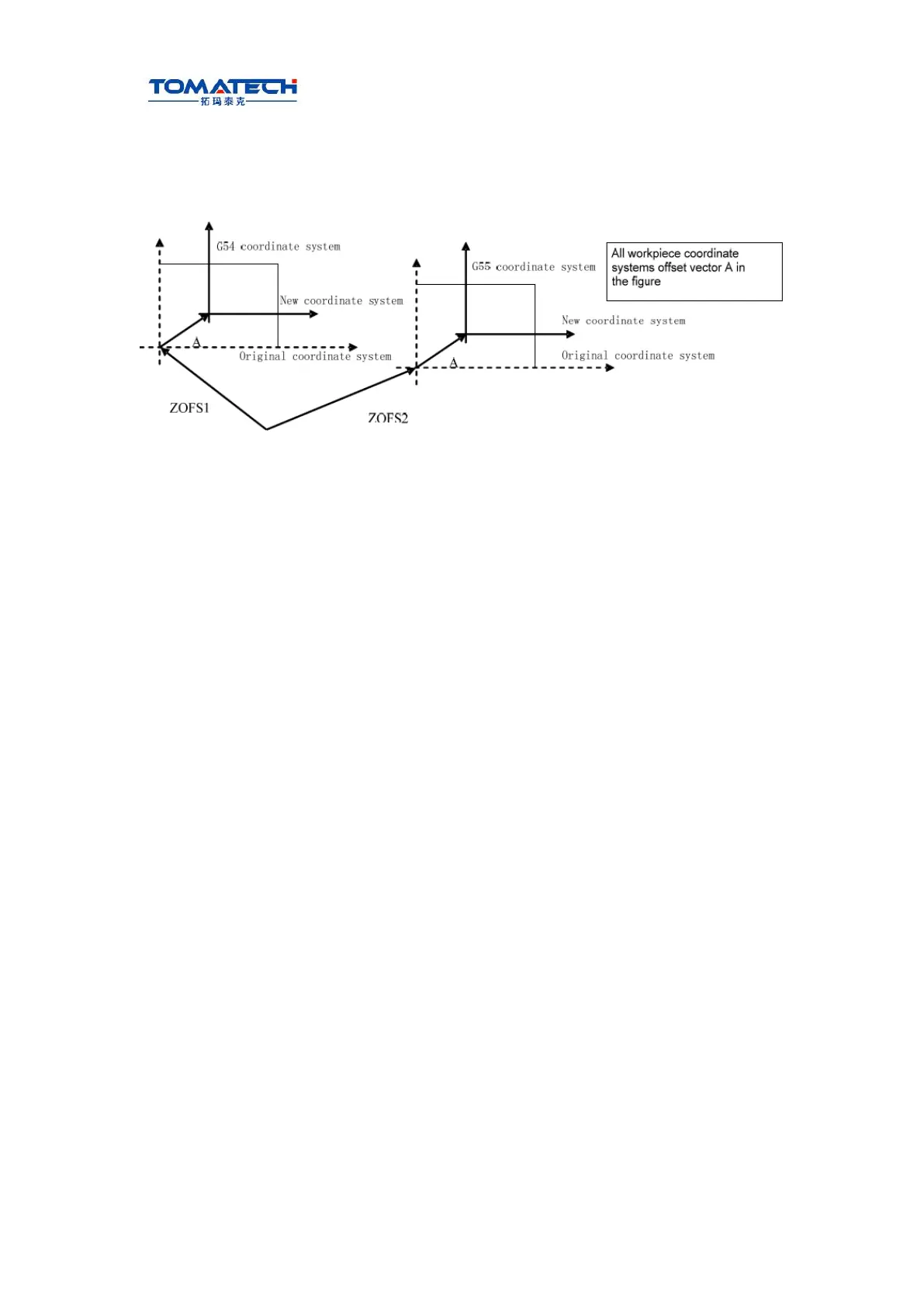

systems, which are shown below:

Ⅰ

Prog

ramming

3.19 Fixed Cycle Command

To simplify programming, the system defines G command of single machining cycle with

one

block to complete the rapid traverse to position, linear/thread cutting and rapid traverse to

return to

the starting point:

G90: axial cutting cycle;

G92: thread cutting cycle;

G94: radial cutting cycle;

G92 will be introduced in section Thread Function.

3.19.1 Axial cutting cycle G90

Command format: G90 X(U) __ Z(W) __ F__; (cylinder cutting)

G90 X(U) __ Z(W) __ R__ F__; (taper cutting)

Command function: From starting point, the cutting cycle of cylindrical surface or taper

surface is completed by radial feeding(X) and axial (Z or X and Z) cutting.

Command specifications:

G90 is modal;

Starting point of cutting: starting position of linear interpolation(cutting feed)

End point of cutting: end position of linear interpolation(cutting feed)

X: X absolute coordinates of cutting end point

U: different value of X absolute coordinate between end point and starting point of cutting

Z: different value of Z absolute coordinate between end point and starting point of cutting

W: different value of Z absolute coordinate between end point and starting point of cutting

R: different value (radius value) of X absolute coordinates between end point and start

point of cutting. When the signs of R is not the same that of U, R│≤│U/2│; when R=0 or

the input is default, the cylinder cutting is executed as Fig.3-17, otherwise, the cone

cutting is executed as Fig. 3-18; unit: mm.

Ranges of X, U, Z, W,R are referred to Table 1-2 of Section 1.4.1, unit: mm/inch.

Cycle process:

Loading...

Loading...