Multi Pro 5800 Hydraulic SystemPage 5 − 59

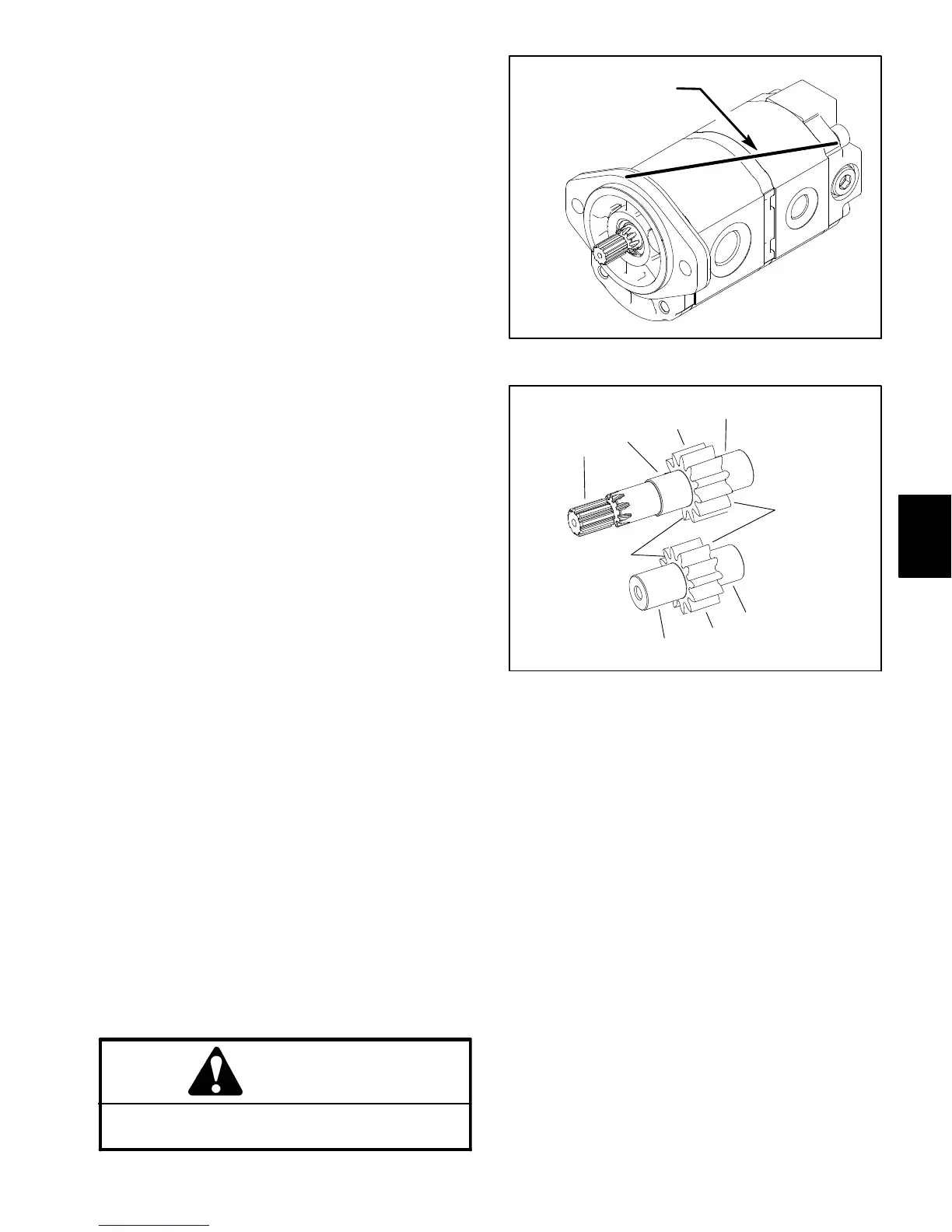

Disassembly (Fig. 43)

NOTE: Disassemble gear pump for cleaning, inspec-

tion and seal replacement only. If internal components

of pump are worn or damaged, the gear pump must be

replaced as a complete assembly. Individual gears,

housings and thrust plates are not available separately.

The relief valve can be replaced separately.

IMPORTANT: Keep bodies, gears, flanges and

thrust plates for each pump section together; do not

mix parts between pump sections.

1. Plug pump ports and thoroughly clean exterior of

pump with cleaning solvent. Make sure work area is

clean.

2. Use a marker to make a diagonal line across the

gear pump for assembly purposes (Fig. 44).

IMPORTANT: Use caution when clamping gear

pump in a vise to avoid distorting any pump compo-

nents.

3. Secure the front cover of the pump in a vise with the

drive shaft pointing down.

4. Loosen, but do not remove, the four (4) screws that

secure pump assembly.

5. Remove pump from vise and remove fasteners.

6. Support the pump assembly and gently tap the pump

case with a soft face hammer to loosen the pump sec-

tions. Be careful to not drop parts or disengage gear

mesh.

IMPORTANT: Mark the relative positions of the gear

teeth and the thrust plates so they can be reassem-

bled in the same position. Do not touch the gear sur-

faces as residue on hands may be corrosive to gear

finish.

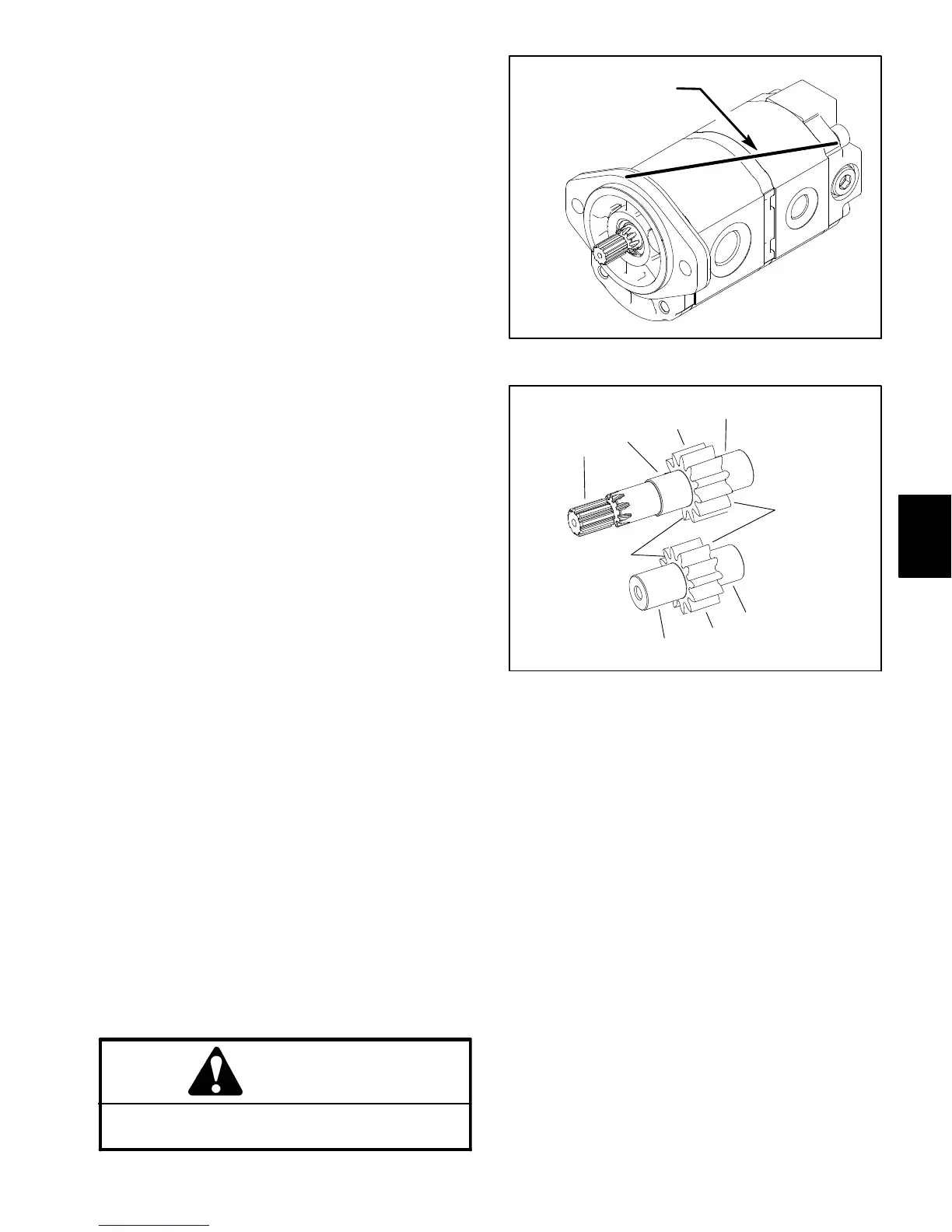

7. Remove the thrust plates and seals from each pump

section. Before removing each gear set, apply marking

dye to mating teeth to retain ”timing”. Pump efficiency

may be affected if the teeth are not installed in the same

position during assembly. Keep the parts for each pump

section together; do not mix parts between sections.

Gear Pump Inspection

1. Remove any nicks and burrs from all parts with

emery cloth.

CAUTION

Use eye protection such as goggles when using

compressed air.

Figure 44

DIAGONAL LINE

P1

P2

1. Gear shaft spline

2. Gear shaft

3. Gear teeth

4. Gear face edge

Figure 45

3

4

1

2

3

2

2

2

4

2. Clean all parts with solvent. Dry all parts with com-

pressed air.

3. Inspect drive gears and idler gears for the following

(Fig. 45):

A. Gear shafts should be free of rough surfaces and

excessive wear at bushing points and sealing areas.

Scoring, rough surfaces or wear on gear shafts indi-

cates need for replacement.

B. Gear teeth should be free of excessive scoring

and wear. Any broken or nicked gear teeth must be

replaced.

C. Inspect gear face edge for sharpness. Sharp

edges of gears will mill into wear plates and, thus,

must be replaced.

Hydraulic

System

Loading...

Loading...