Multi Pro 5800 ChassisPage 9 − 5

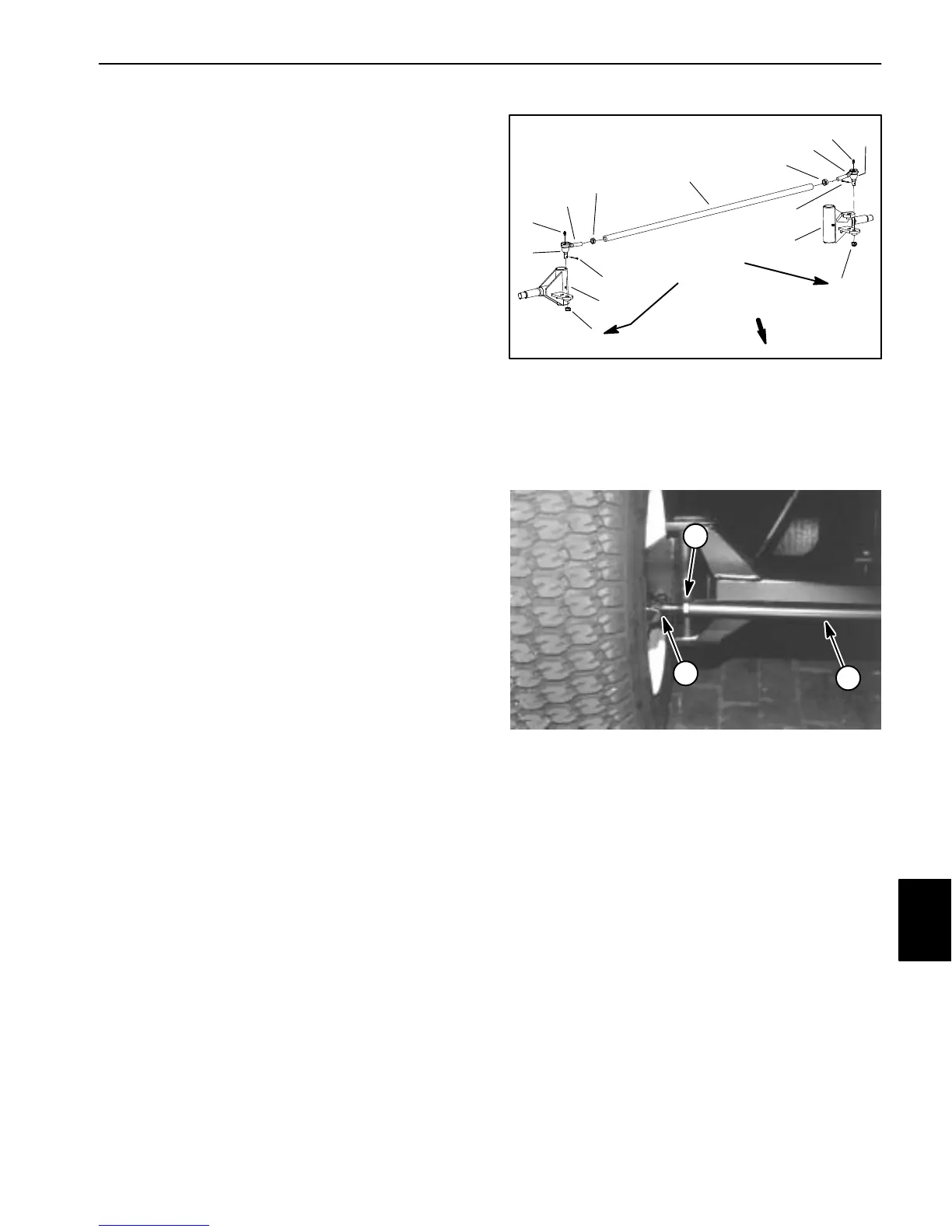

Tie Rod

Removal (Fig. 3)

1. Park machine on a level surface, stop engine, en-

gage parking brake and remove key from the ignition

switch.

NOTE: Left side tie rod end has a left hand threaded

jam nut.

2. Loosen jam nut on tie rod end.

3. Remove cotter pin and castle nut that secure tie rod

end to spindle.

4. Use a suitable puller (pickle fork) to separate tie rod

end from spindle.

5. When removing tie rod end from tie rod, count the

number of revolutions it takes to remove so new tie rod

end can be installed with minimal change to front wheel

toe−in.

Installation (Fig. 3)

1. Install dust boot on new tie rod end.

2. Thread tie rod end into tie rod the same number of

revolutions as the old tie rod end took to remove.

3. Install grease fitting into tie rod end.

4. Insert tie rod end shaft into spindle and secure with

castle nut. Torque castle nut from 20 to 25 ft−lb (27 to

33 N−m). If necessary, nut can be tightened slightly fur-

ther to align cotter pin position in spindle and nut. Install

cotter pin.

5. Grease tie rod end.

6. Check front wheel toe−in and adjust if needed. Front

wheel toe−in should be from 1/8 to 1/4 inch (3.2 to 6.4

mm).

7. Adjust steering stop bolt on each spindle so that at

full turn, there is a gap from 1/16” to 1/8” (1.6 to 3.2 mm)

between the head of the stop bolt and the axle stop lug.

8. Verify that there is at least a 1/16” (1.6 mm) gap be-

tween the tie rod and front axle when turning full right to

left.

9. After assembly is complete, make sure that steering

components do not contact hoses and/or electrical har-

ness wires.

1. Tie rod

2. Jam nut (RH thread)

3. RH tie rod end

4. Grease fitting

5. Castle nut

6. Cotter pin

7. Dust boot

8. RH spindle

9. LH spindle

10. LH tie rod end

11. Jam nut (LH thread)

Figure 3

6

9

1

5

10

2

3

4

7

8

4

5

6

7

11

FRONT

20 to 25 ft−lb

(27 to 33 N−m)

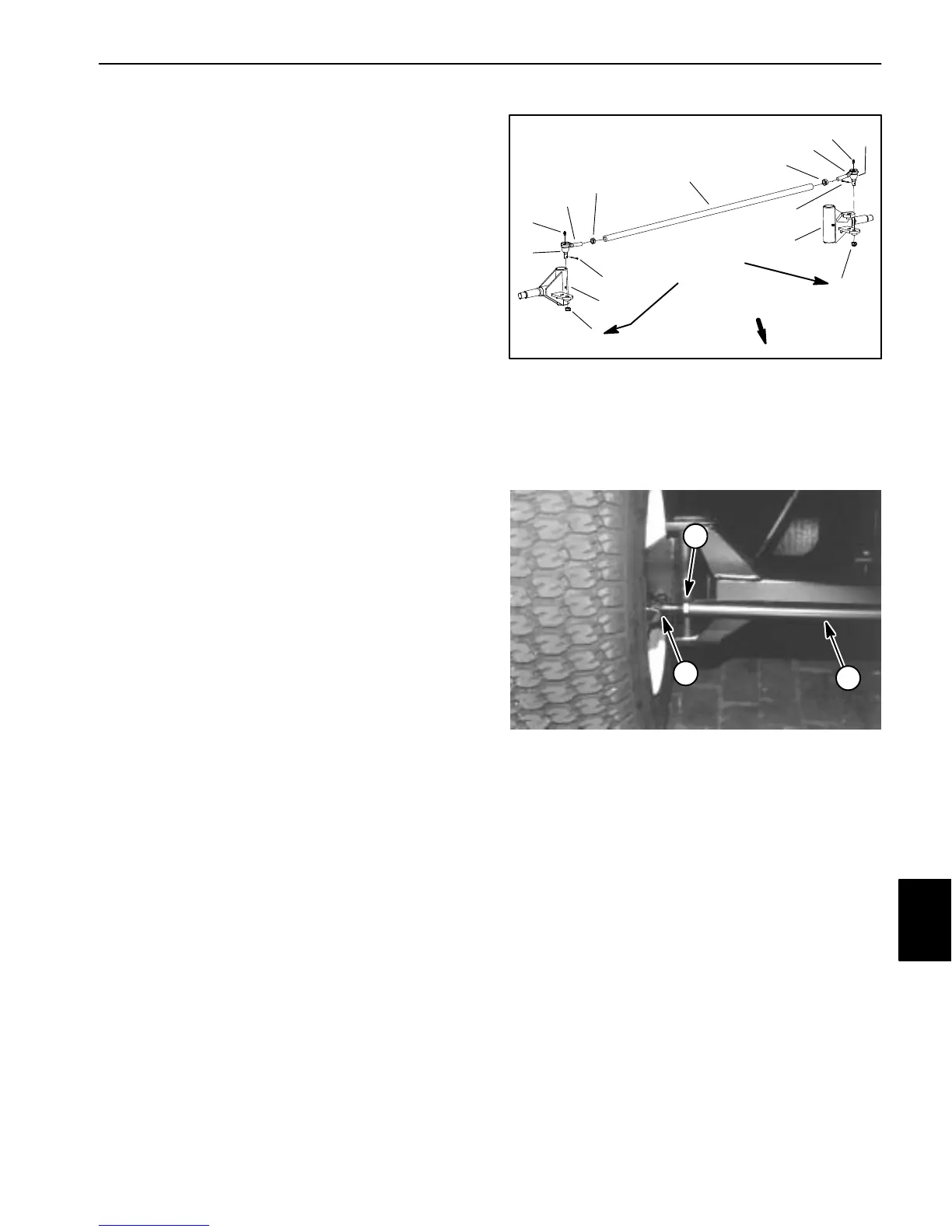

1. Tie rod

2. Jam nut

3. Tie rod end

Figure 4

2

1

3

Chassis

Loading...

Loading...