Multi Pro 5800Page 6 − 54Electrical System

Application−Rate Switch

The application−rate (increase/decrease) switch is lo-

cated on the instrument panel directly below the pres-

sure gauge (Fig. 71). The application−rate switch is an

input to the TEC. When all necessary spray control con-

ditions are met, the TEC modifies the current applied to

the spray pump control manifold solenoid valve using a

PWM (pulse width modulation) signal. Pressing the

switch to the increase position increases the frequency

of the PWM signal to the valve coil which increases hy-

draulic flow to the spray pump motor. Moving the switch

to the decrease position reduces the frequency of the

PWM signal to the valve coil and results in less hydraulic

flow to the spray pump.

Testing

1. Park machine on a level surface, stop engine and en-

gage parking brake. Remove key from ignition switch.

2. Locate the switch to be tested ans disconnect the

wire harness electrical connector from the switch.

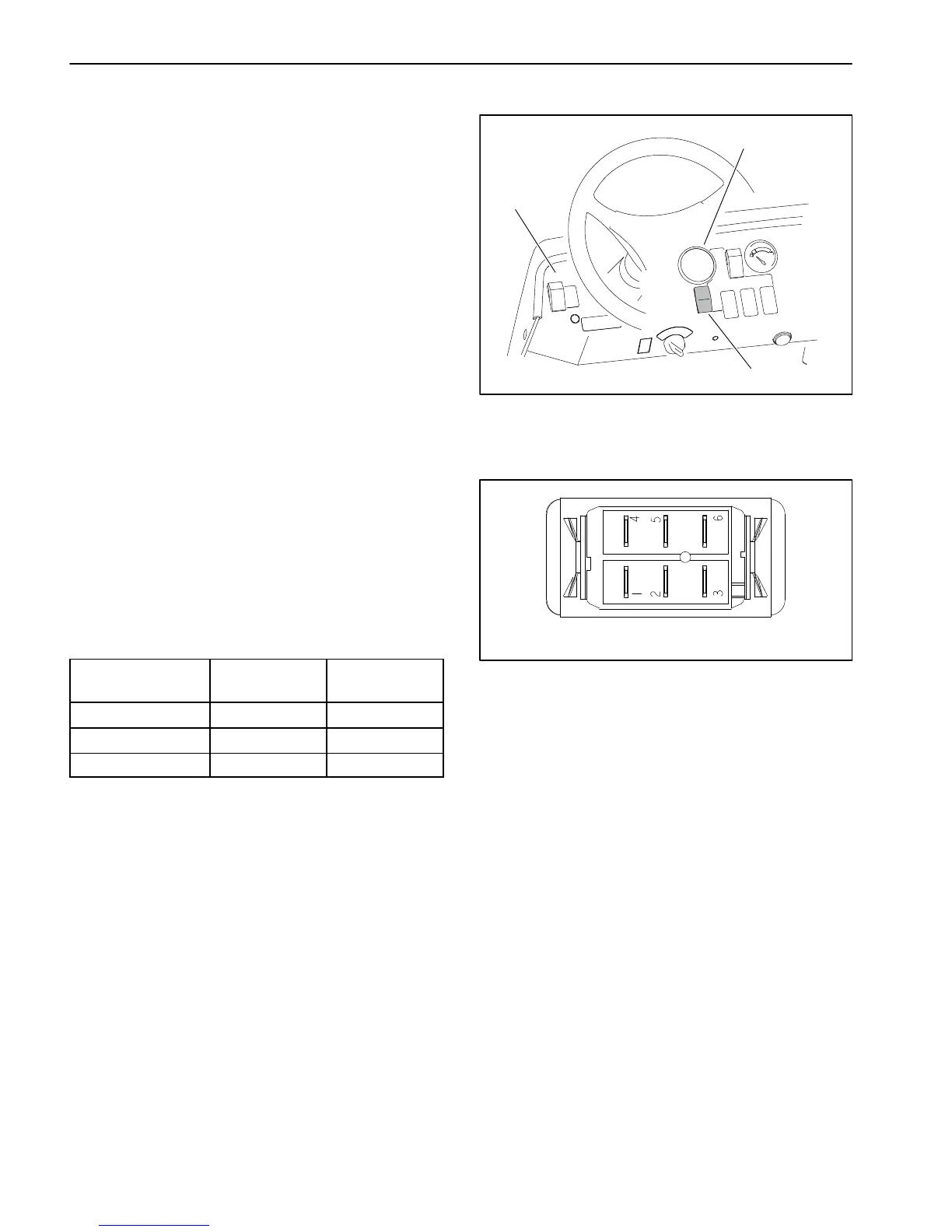

3. With the use of a multimeter (ohms setting), the

switch functions may be tested to determine whether

continuity exists between the various terminals for each

position. The switch terminals are marked as shown

(Fig. 72) and the circuitry of the application−rate switch

is shown in the chart (Fig. 70). Verify continuity between

switch terminals.

SWITCH

POSITION

CLOSED

TERMINALS

OPEN

TERMINALS

INCREASE 2 + 3, 5 + 6 2 + 1, 5 + 4

OFF NONE ALL

DECREASE 2 + 1, 5 + 4 2 + 3, 5 + 6

Figure 70

4. Replace switch if necessary.

5. If the switch tests correctly and a circuit problem still

exists, check the wire harnesses (see Electrical Sche-

matics and Wire Harness Drawings and Diagrams in

Chapter 11 − Foldout Drawings in this manual).

6. Connect the wire harness connector to the switch af-

ter testing is complete.

1. Instrument panel

2. Application−rate switch

3. Pressure gauge

Figure 71

1

2

3

Figure 72

BACK OF SWITCH

NOTE: Application−rate switch terminals 4, 5 and 6 are

not used on Multi Pro 5800 machines.

Loading...

Loading...