Multi Pro 5800Page 6 − 66Electrical System

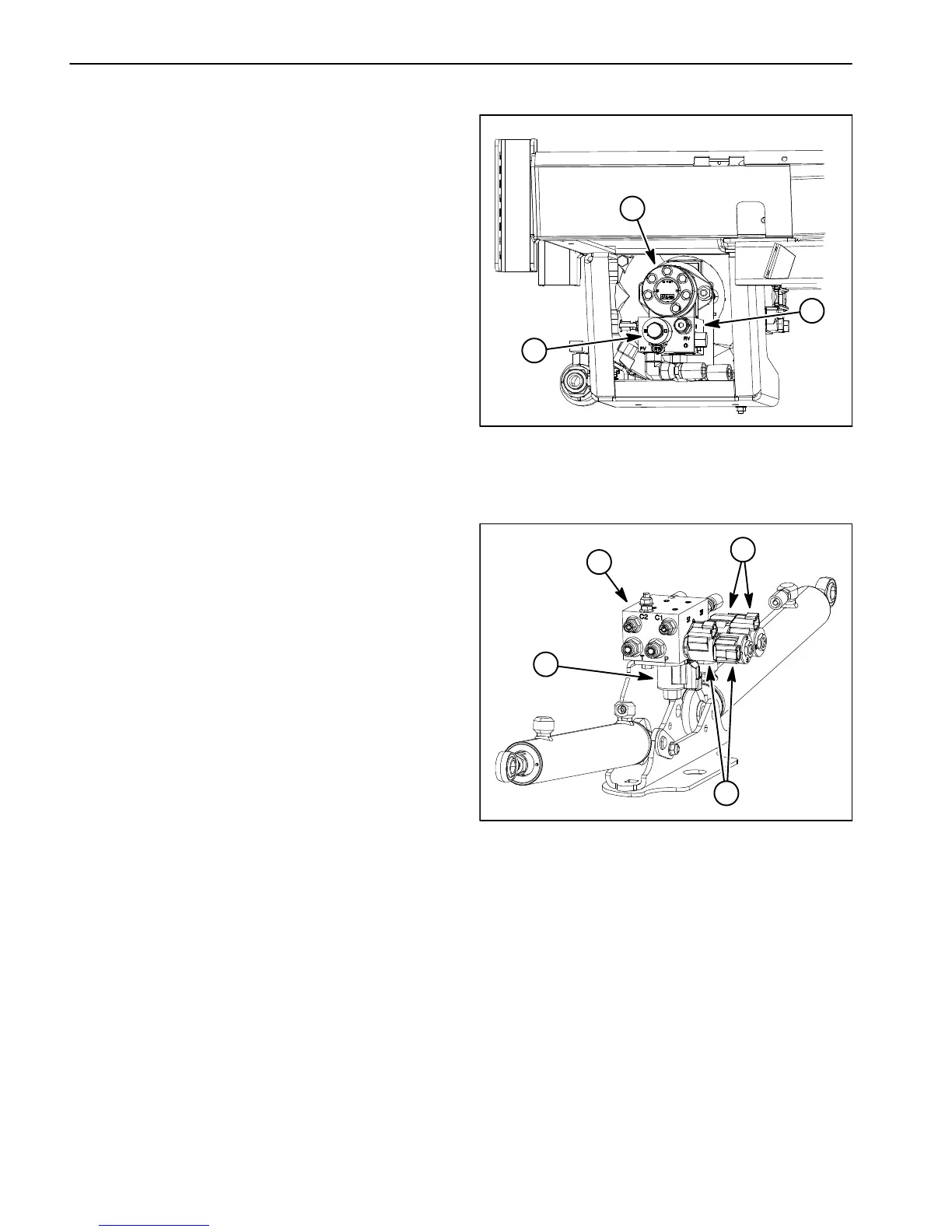

Hydraulic Valve Solenoid Coils

The Multi Pro 5800 hydraulic system uses several hy-

draulic solenoid valve coils for system control. The

spray pump control manifold includes one (1) single coil

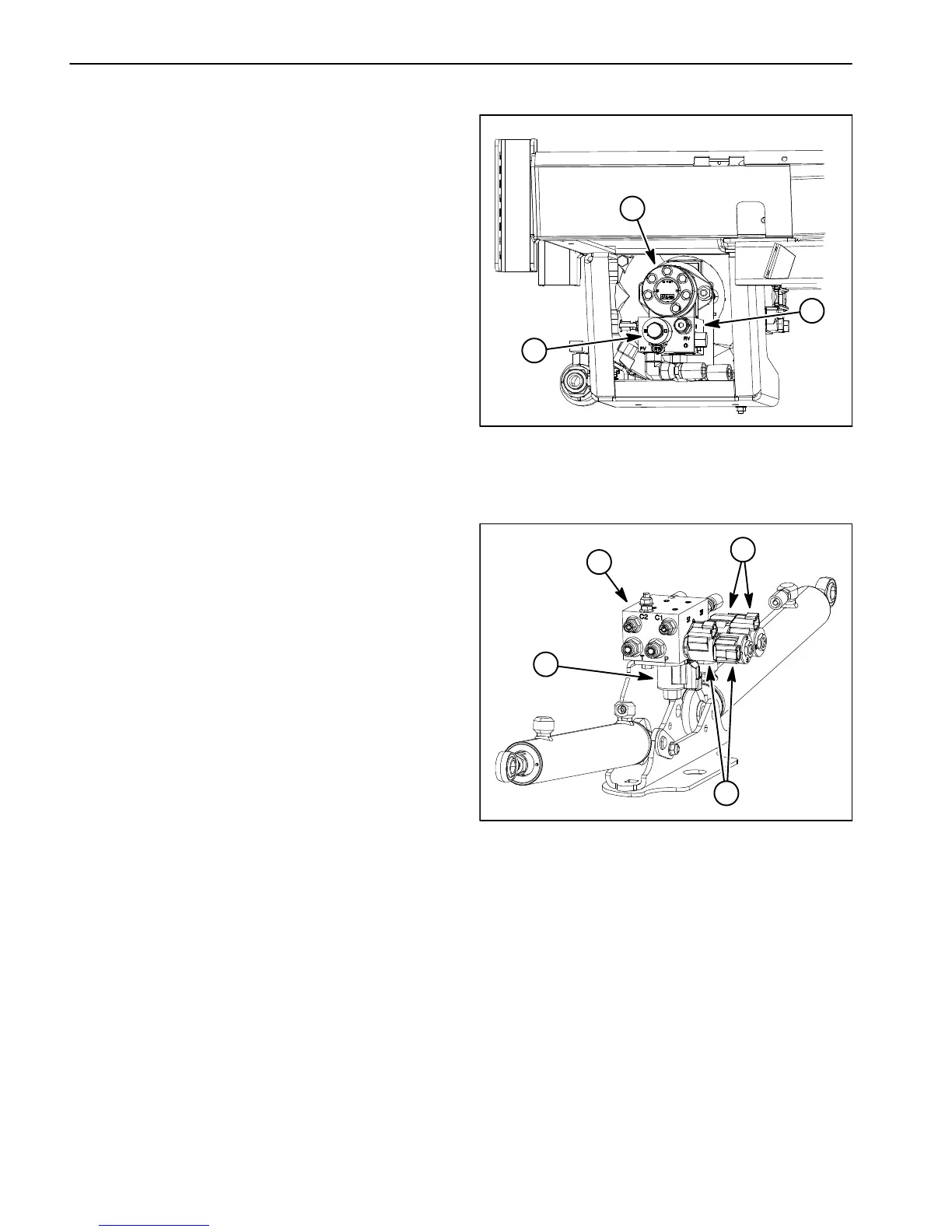

solenoid valve (Fig. 97). The standard boom lift control

manifold includes one (1) single coil solenoid valve and

two (2) dual coil solenoid valves (Fig. 98). When the so-

lenoid coils are energized, hydraulic valve shift occurs

to control hydraulic flow. Testing of the coils can be done

with the coil installed on the hydraulic valve.

NOTE: The boom lift control manifold for machines with

an optional ultra sonic boom system includes two (2) sin-

gle coil solenoid valves and two (2) dual coil solenoid

valves. See Chapter 10 − Ultra Sonic Boom System in

this manual for additional information.

Testing

1. Park machine on a level surface, stop engine and en-

gage parking brake. Remove key from ignition switch.

2. Locate solenoid valve coil to be tested and discon-

nect wire harness connector from coil.

NOTE: Prior to taking small resistance readings with a

digital multimeter, short the meter test leads together.

The meter will display a small resistance value (usually

0.5 ohms or less). This resistance is due to the internal

resistance of the meter and test leads. Subtract this val-

ue from from the measured value of the solenoid you are

testing.

NOTE: Solenoid coil resistance should be measured

with solenoid at approximately 68F (20C). Resistance

may be slightly different than listed at different tempera-

tures. Typically, a failed solenoid coil will either be

shorted (very low or no resistance) or open (infinite re-

sistance).

3. Using a multimeter (ohms setting), measure resis-

tance between the two connector terminals on the sole-

noid valve coil. The resistance for the solenoid coils is

identified below:

A. The resistance of the solenoid coil on the spray

pump manifold should be 4.5 ohms.

B. The solenoid coils on the boom lift manifold are

identical. Resistance of these coils should be 8.8

ohms.

NOTE: Because the solenoid valve coils on the boom

lift control manifold are identical, they can be exchanged

to assist in troubleshooting. If the problem follows the

exchanged coil, an electrical problem likely exists with

the coil.

1. Spray pump drive motor

2. Spray pump control

manifold

3. Solenoid coil (PV)

Figure 97

3

1

2

1. Boom lift manifold

2. Solenoid coil (S1)

3. Solenoid coil (S2)

4. Solenoid coil (S3)

Figure 98

1

2

4

3

4. If solenoid coil resistance is incorrect, replace coil

(see Spray Pump Control Manifold Service or Boom Lift

Control Manifold Service in the Service and Repairs

section of Chapter 5 − Hydraulic System).

5. If the solenoid coil tests correctly and a circuit prob-

lem still exists, check wire harness (see Electrical Sche-

matic and Wire Harness Drawings in Chapter 11 −

Foldout Drawings in this manual).

6. After testing is completed, connect wire harness

electrical connector to the solenoid valve coil.

Loading...

Loading...