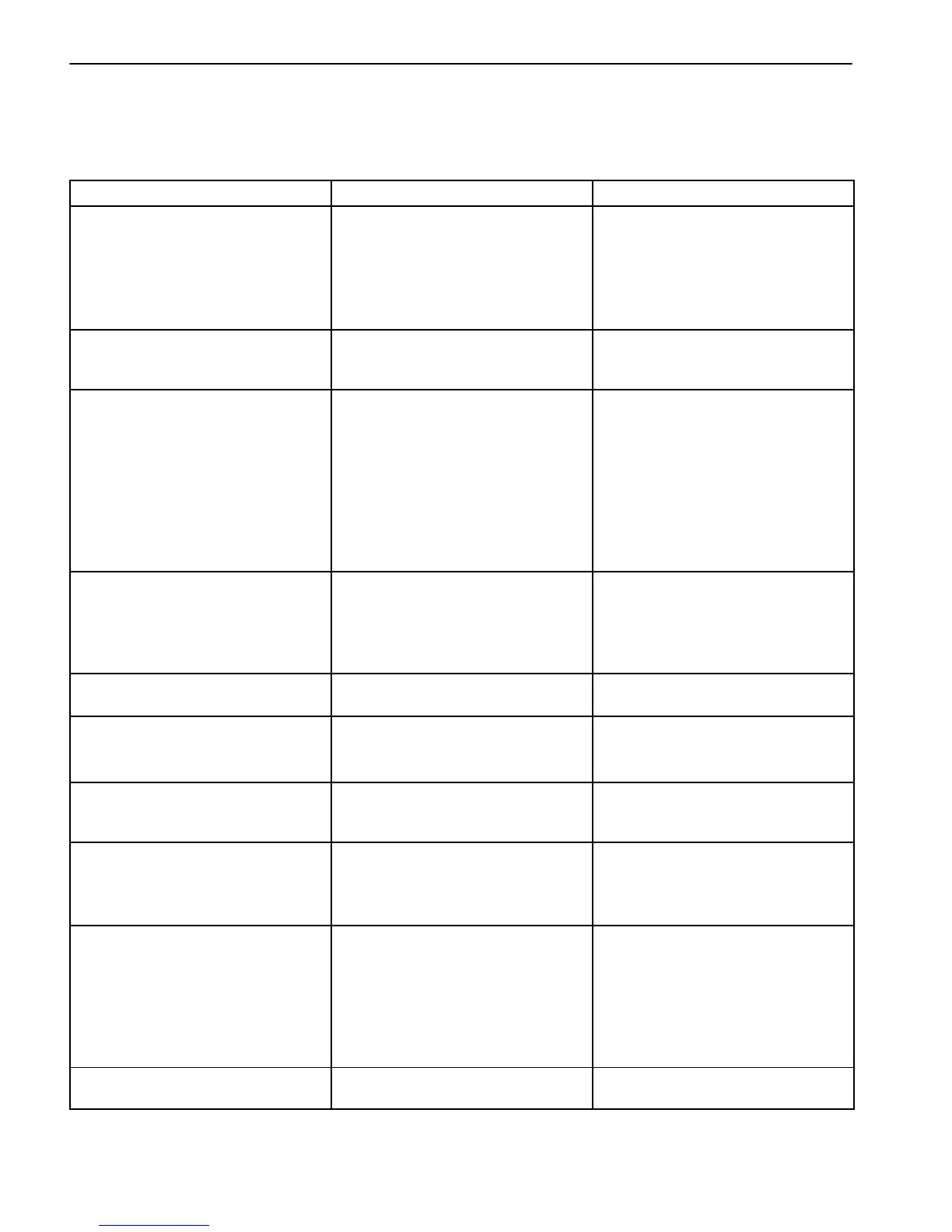

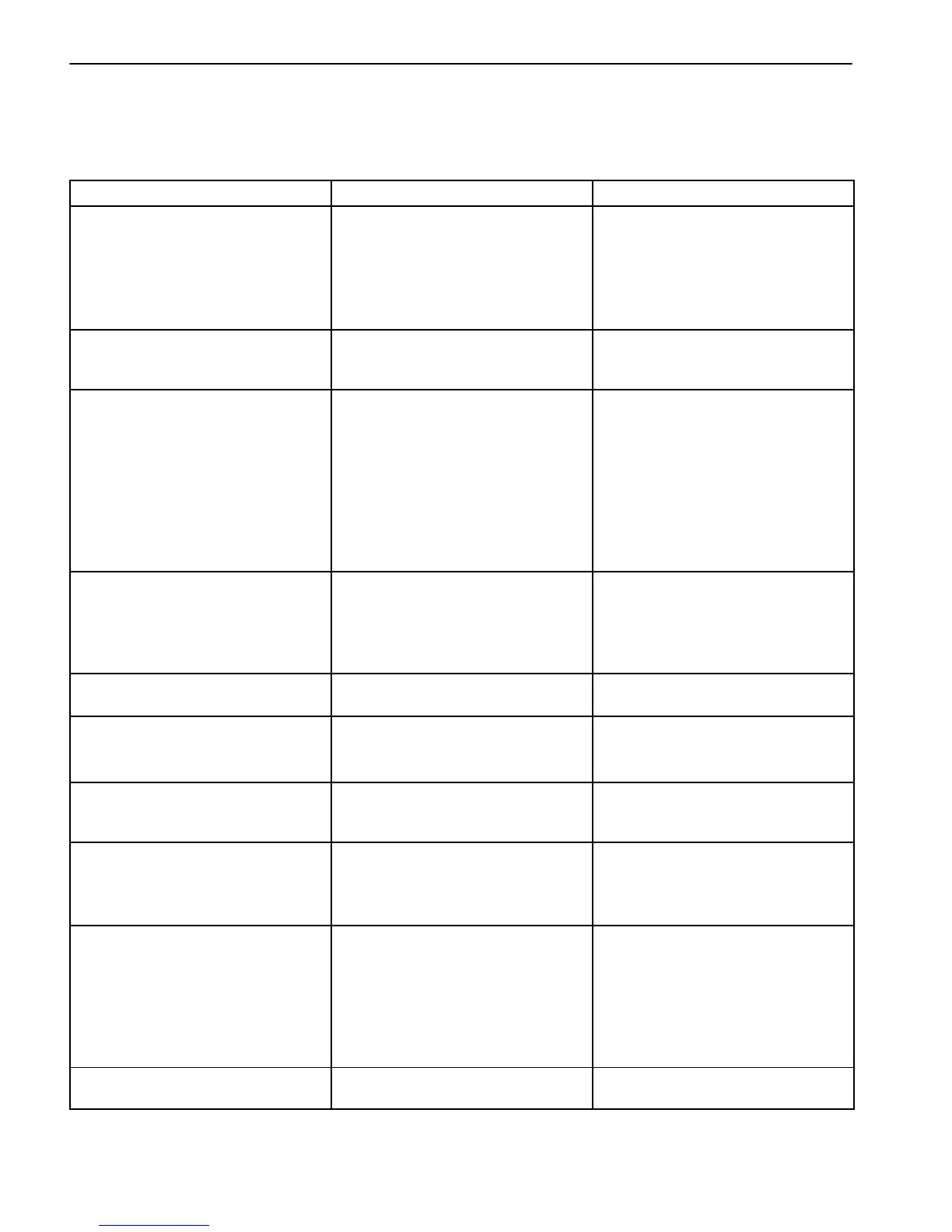

Multi Pro 5800Page 8 − 42GeoLink Spray System

Guidance and Rate Management System

Use the following tables to assist in troubleshooting spe-

cific issues with the guidance and rate management

(dry) portion of the spray system.

Problem

Possible Cause Corrective Action

There is no power to the display. The connectors are not installed

correctly

The fuse(s) for the GeoLink sys-

tem blown

The battery connections are loose

Ensure the connectors are in-

stalled correctly at the back of the

display

Replace the fuse(s)

Secure the battery connections

The monitor is frozen There is a malfunction with the

software

Hold in the green button on the

back of the display until the front

LED lights flash

The sprayer does not spray The virtual or external master

switch is OFF

The boom section switches on the

operator console (between the

seats) are OFF

No job and boundary are created

The incorrect nozzle is selected in

sprayer−control setup menu

Set the virtual or external master

switch to ON

Set the boom section switches on

the operator console (between the

seats) to ON

Create a job and boundary

Select the correct nozzle in

sprayer−control setup menu that

matches the nozzles being used

The No GPS alarm is on The display is not connected to

GPS receiver correctly

The machine is under trees or oth-

er obstructions

Ensure the connections are in-

stalled correctly

Allow the machine to make con-

nection after driving under obstruc-

tions

The sprayer sprays outside bound-

aries

The auto section control (ASC) is

set to unlimited or OFF

Set the auto section control (ASC)

to field boundary

You cannot create boundaries The display is not in standard op-

erating mode

There is no field created

Switch the user profile to standard

operating mode

Create a field

The machine is not shown on the

screen

The display screen map has been

moved (panned)

Select the center−map under

sprayer icon on the view controls

menu

The lights are not blinking on the

GPS receiver located on the

ROPS

There is no power to the GPS re-

ceiver

The GPS receiver (AGI−4) is off−

line

Ensure the connectors are in-

stalled correctly

The pressure is not high enough The nozzle size used is incorrect

The nozzle size selected in the

display does not match the noz-

zles on the booms

The agitation is set too low

Refer to the nozzle selection chart

for the proper nozzle sizing

Ensure the nozzle size selected in

the display matches the boom noz-

zles

Adjust the agitation until the de-

sired pressure is realized

The LED lights on the controller

(ASC−10) are not on

There is no power to the controller

(ASC−10)

Ensure the connectors are in-

stalled correctly

Loading...

Loading...