Multi Pro 5800 Page 6 − 3 Electrical System

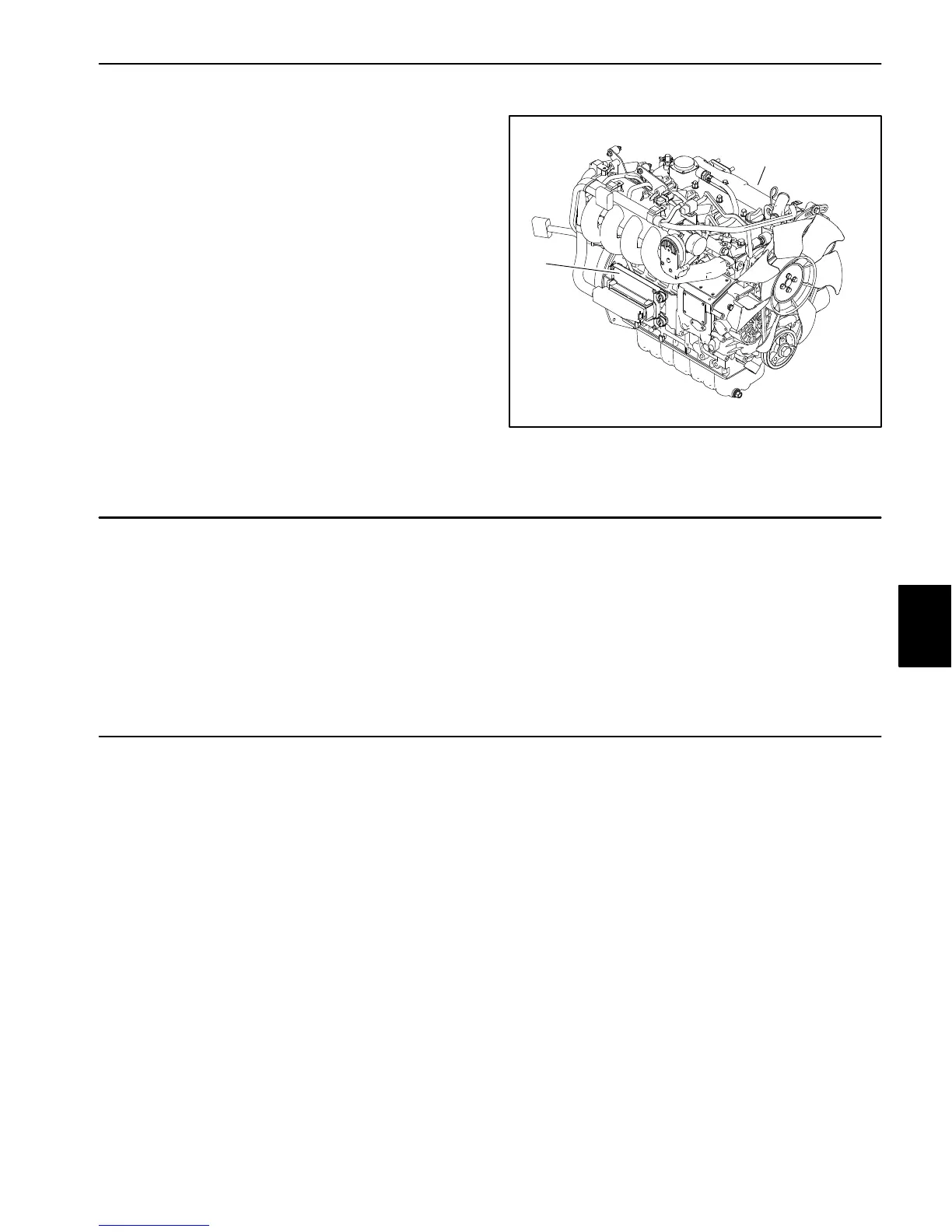

Kubota Gasoline Engine Electronic Control Unit (ECU)

The Kubota gasoline engine that powers Multi Pro 5800

models 41394 and 41594 uses an Electronic Control

Unit (ECU) for engine management. The engine ECU

communicates with the Toro Electronic Controller (TEC)

and the InfoCenter display on the machine. The gaso-

line engine ECU is located on the right side of the en-

gine. All wire harness electrical connectors should be

plugged into the ECU before the machine ignition switch

is moved from the OFF position to either the ON or

START position.

If the engine ECU is to be disconnected for any reason,

make sure that the ignition switch is in the OFF position

with the key removed for a minimum of thirty (30) sec-

onds before disconnecting the engine ECU. Also, to pre-

vent possible ECU damage when welding on the

machine, disconnect the engine ECU from the machine

before welding.

Figure 2

1. Gasoline engine

2. Engine ECM

1

2

Kubota Engine Electrical Components

When servicing or troubleshooting the engine electrical

components, use the correct engine service manual and

troubleshooting manual. Also, for Gasoline engine pow-

ered units, your Toro Distributor can use the Kubota

Gasoline Service Tool (KGST) and software to confirm

the real−time engine running status and to offer timely

technical services. Contact your Toro distributor for as-

sistance in Kubota gasoline engine troubleshooting.

CAN−bus Communications

The TEC controller, the InfoCenter Display, and in the

case of gasoline engine powered machines the Kubota

Engine Controller communicate with each other on a

Controller Area Network (CAN) bus system. Using this

network allows the traction unit to fully integrate all the

different electrical components of the tractor and bring

them together as one. The CAN bus system reduces the

number of electrical components and connections used

on the machine and allows the number of wires in the

wire harness to be significantly reduced. The integration

of electrical functions also allows the InfoCenter Display

to assist with electrical system diagnostics.

Each of the components that is controlled by the CAN

bus link only needs four (4) wires to operate and commu-

nicate to the system: CAN High, CAN Low, power and

ground. The ignition switch needs to be in the RUN or

START position for the components on the network to be

active.

Two (2) specially designed, twisted wires form the CAN

bus. These wires provide the data pathways between

the components on the network. The engineering term

for these cables are CAN High and CAN Low. The bus

wires for the 12 VDC circuits are black/white and red/

white. At the end of the twisted pair of bus cables is a 120

ohm termination resistor.

IMPORTANT: The termination resistor at the end of

the bus wires is required for proper electrical sys-

tem operation.

Electrical

System

Loading...

Loading...