Multi Pro 5800 Page 6 − 61 Electrical System

Relays with Four (4) Terminals

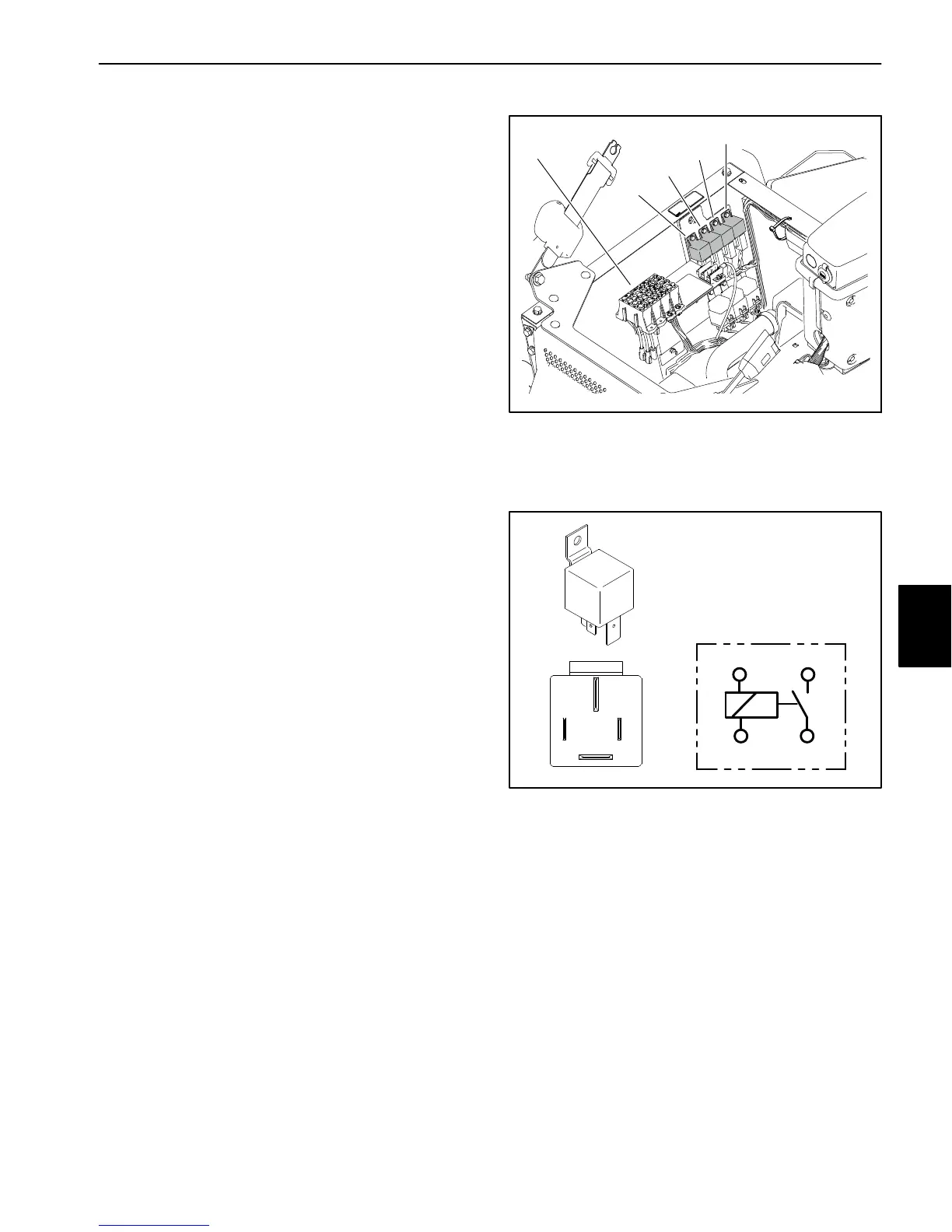

The Multi Pro 5800 uses a number of electrical relays

that have four (4) terminals. The relays is located under

the operator seat next to the fuse blocks (Fig. 87). The

relays can be identified by a tag near the relay wire har-

ness connector.

All Multi Pro 5800 machines use a four (4) terminal

main power relay to provide current to most of the

fuse protected circuits (TEC, InfoCenter display,

spray system components, speed lock, power point,

headlights and optional electric equipment). The

power relay is energized when the ignition switch is

in the RUN or START position.

Machines with diesel engines use a four (4) terminal

glow relay to provide current to the engine glow

plugs. The glow relay is energized by the Kubota

glow plug controller for approximately six (6) sec-

onds when the ignition switch is placed in the RUN/

PREHEAT position and while the ignition switch is

held in the START position.

If the machine is equipped with an optional clean

tank rinse kit, an additional four (4) terminal relay is

added to the electrical system. The rinse pump relay

is energized by the TEC when the rinse pump switch

is pressed.

If the machine is equipped with an optional hose reel

kit, an additional four (4) terminal relay is added to

the electrical system. The hose reel relay is ener-

gized when the hose reel motor switch is pressed.

The hose reel relay is located in the hose reel control

box (not shown).

Testing

1. Park machine on a level surface, stop stop engine

and engage parking brake. Remove key from ignition

switch.

2. Raise operator seat and locate the desired relay. Dis-

connect wire harness connector from the relay and re-

move the relay from the machine.

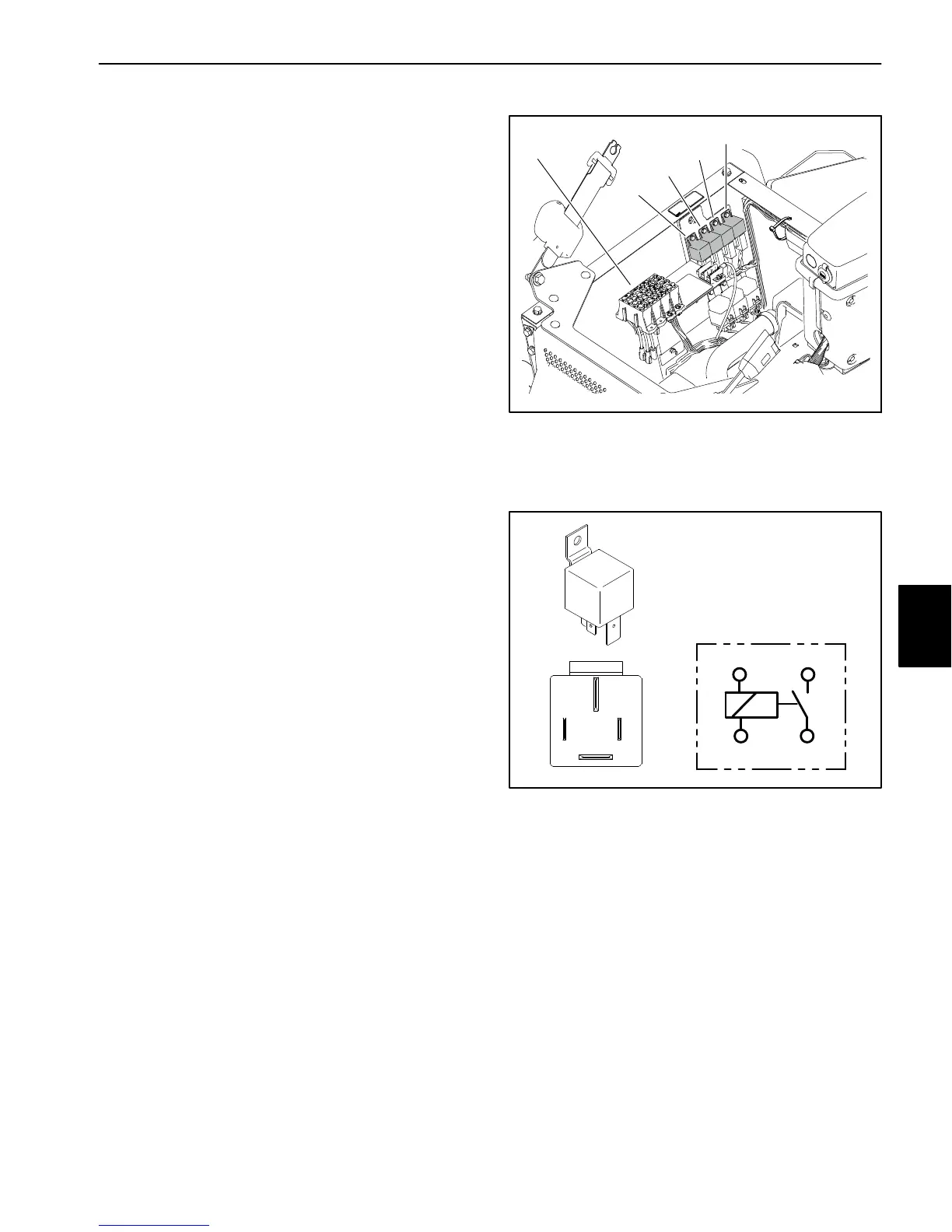

3. The relay terminals are marked as shown (Fig. 88).

NOTE: Prior to taking small resistance readings with a

digital multimeter, short the meter test leads together.

The meter will display a small resistance value (usually

0.5 ohms or less). This resistance is due to the internal

resistance of the meter and test leads. Subtract this val-

ue from from the measured value of the component you

are testing.

4. Using a multimeter, verify that coil resistance be-

tween terminals 86 and 85 is approximately 72 ohms.

1. Fuse blocks

2. Main power relay

3. Glow relay

(diesel engines only)

4. Optional kit relays

Figure 87

1

3

2

4

4

Figure 88

86 87

85 30

85 86

87

30

5. Connect multimeter (ohms setting) leads to relay ter-

minals 30 and 87. Ground terminal 86 and apply +12

VDC to terminal 85. The relay should make and break

continuity between terminals 30 and 87 as +12 VDC is

applied and removed from terminal 85.

6. Replace relay if testing determines that the relay is

faulty.

7. If the relay tests correctly and a circuit problem still

exists, check wire harness (see Electrical Schematic

and Wire Harness Drawings in Chapter 11 − Foldout

Drawings in this manual).

8. Install relay and connect to wire harness.

9. Lower and secure operator seat.

Electrical

System

Loading...

Loading...