Multi Pro 5800 Page 6 − 37 Electrical System

Machine Faults

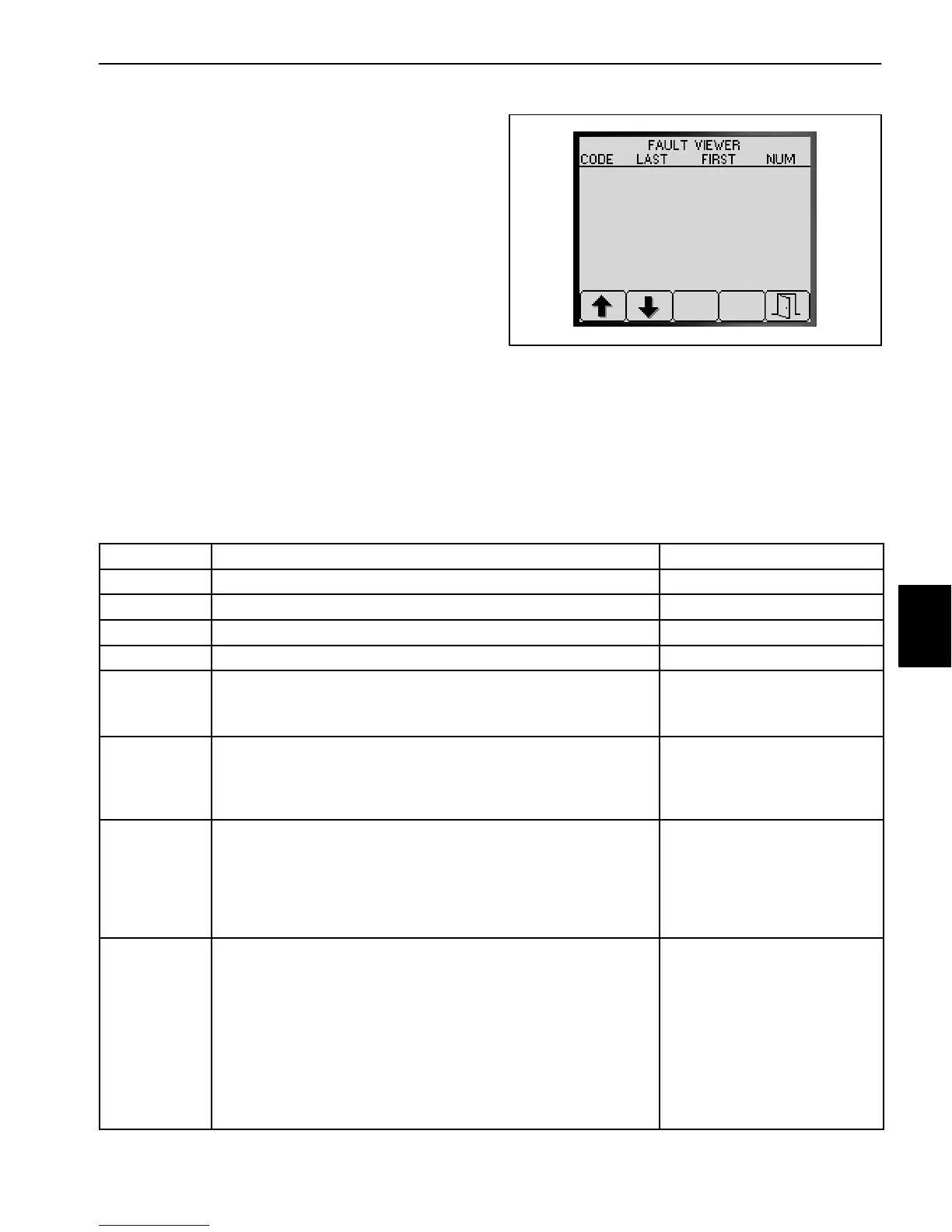

Machine faults are generated by the Toro Electronic

Controller (TEC) to identify an electrical system mal-

function (fault) that occurs during machine operation.

When a machine fault occurs, an audible alarm will

sound and the InfoCenter will display information about

the fault. Machine faults can be viewed via the InfoCen-

ter Diagnostic Screen Fault Viewer (Fig. 41). See Info-

Center Diagnostic Screen Fault Viewer in this chapter

for additional information.

For machines with gasoline engines, the Kubota Elec-

tronic Control Unit (ECU) can also generate electrical

faults. The faults generated by the ECU are specific to

the engine (see Engine Faults in this chapter for addi-

tional information).

The list below identifies the fault codes that are gener-

ated by the Toro Electronic Controller (TEC) to identify

an electrical system malfunction (fault) that occurred

during machine operation for revision D software. Use

the InfoCenter Display Diagnostics > Fault Viewer for

fault retrieval.

Figure 41

14 39.4 39.4 1

Fault Code Fault Description Recommended Action

1 TEC is faulty Replace TEC

2 One or more of the TEC output fuses (7.5 Amp) is faulty Replace fuse

3 Main power relay or circuit wiring is faulty Test main power relay

4 Charging system or circuit wiring is faulty Test charging system

14 InfoCenter software is not recognized by TEC Reload system software

Contact your Authorized Toro

Distributor

17 Starter timeout

(starter has been engaged for more than 30 seconds)

Allow starter to cool before

reattempting to start engine

Troubleshoot engine starting

issues

18 Neutral switch stuck in neutral position

(neutral switch reports it is in the neutral position, yet vehicle

speed is at or above 2 MPH for approximately 10 seconds)

Faults resets if speed drops below threshold, operator gets out

of seat, neutral switch indicates not in neutral, or system is

placed in Stationary Test Mode

Check Neutral Switch for ad-

justment and function

Check harness connections to

Neutral Switch

19 Spray System Fault − flow meter not working correctly or

harness fault (No flow detected when based upon boom, pump

and pressure it indicates there should be)

Spray pump is ON,Master Boom switch is ON, at least one

boom is ON, spray pressure is above 20 PSI, the booms have

been on long enough for the system to stabilize and vehicle

speed is fast enough for automatic application−rate control to

be enabled

Check the flow meter harness

for proper connection.

Confirm fluid flow at spray

nozzles. If so, flow should be

displayed on the flow rate me-

ter. If no fluid flow at spray

nozzles, begin checking the

spray system for a blockage.

Check flow meter for proper

function.

Electrical

System

Loading...

Loading...