Multi Pro 5800 Page 6 − 73 Electrical System

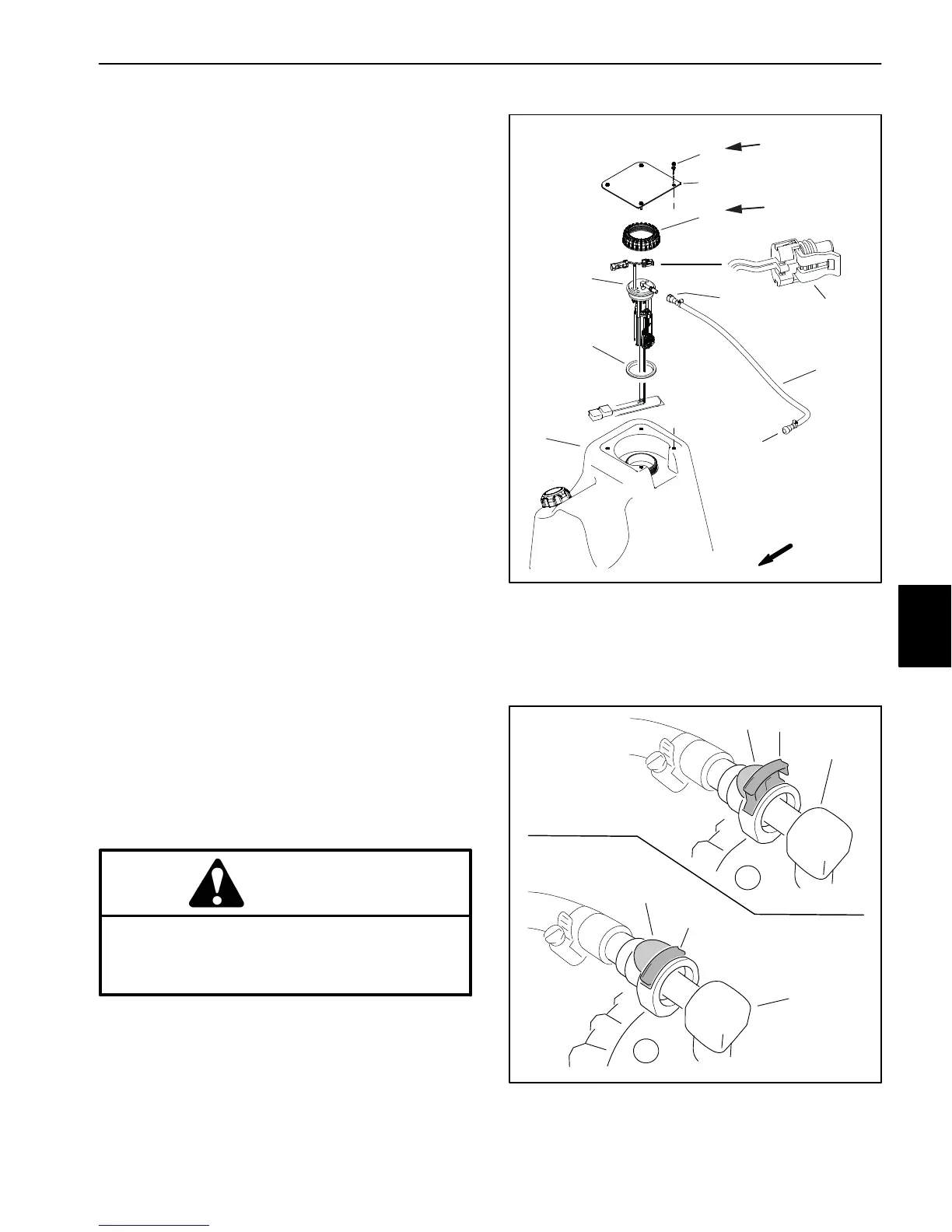

Fuel Level Sender (Gasoline Engines Only)

On Multi Pro 5800 machines with a Kubota gasoline en-

gine, the fuel sender is a component of the fuel pump/

level sender assembly which is secured to the top of the

fuel tank (Fig. 108). The resistance of the fuel sender de-

creases as the fuel level in the fuel tank decreases. The

fuel sender is connected to a fuel gauge mounted to the

instrument panel.

Testing

See Fuel Pump (Gasoline Engines Only) in this chapter

for information on testing the fuel pump portion of the fu-

el pump/level sender assembly.

1. Park machine on a level surface, stop engine and en-

gage parking brake.

2. Remove fuel tank cover and disconnect both ma-

chine wire harness connectors from the fuel pump/

sender assembly.

3. To test the circuit wiring and instrument panel fuel

gauge, turn ignition switch to RUN/PREHEAT. The in-

strument panel fuel gauge should indicate full. Turn igni-

tion switch OFF and proceed with fuel sender testing if

circuit wiring and instrument panel fuel gauge are func-

tioning correctly.

4. Disconnect the fuel supply hose from the fuel pump/

level sender.

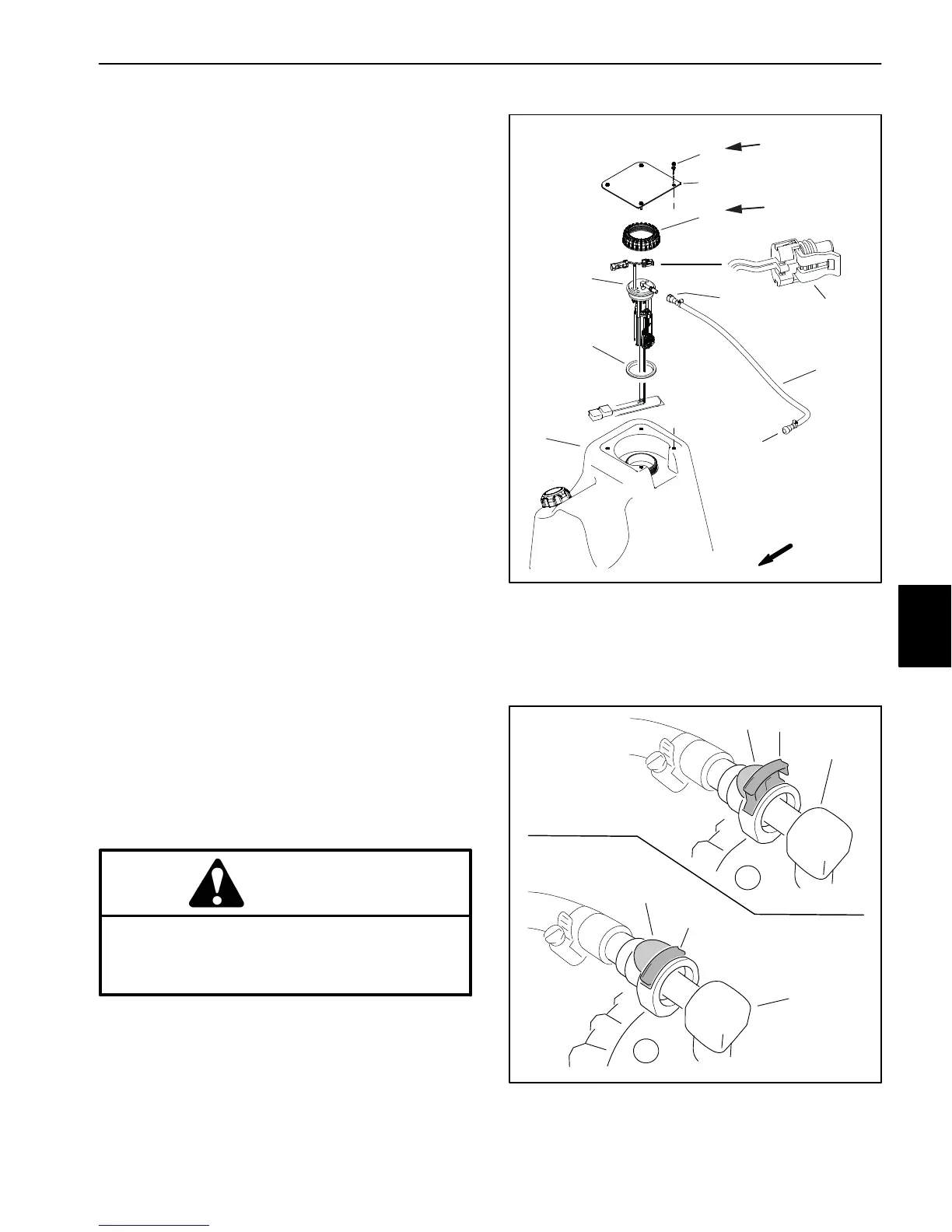

A. Lift supply hose barb fitting lock up to unlock

fitting (Fig. 109).

B. Press barb fitting tab and pull fitting from fuel

pump/level sender.

5. Remove cap and carefully lift fuel pump/level sender

and gasket from fuel tank. Clean all fuel from the fuel

pump/sender.

CAUTION

Make sure fuel pump/level sender is completely

dry (no fuel on it) before testing. Perform test

away from the fuel tank to prevent an explosion

or fire from sparks.

1. Fuel tank

2. Gasket

3. Fuel pump/level sender

4. Flange head screw (4)

5. Tank cover

6. Cap

7. Fuel supply hose

8. Barb fitting

9. Fuel sender harness

connector

Figure 108

FRONT

8

7

6

5

4

TO

FUEL

RAIL

3

2

13 to 65 in−lb

(1 to 7 N−m)

10 to 12 in−lb

(1 N−m)

1

9

Figure 109

1. Fuel pump/level sender

fitting

2. Barb fitting lock (down)

3. Barb fitting lock (up)

4. Barb fitting tab

1

1

2

3

4

4

LOCKED

UNLOCKED

Electrical

System

Loading...

Loading...