Multi Pro 5800Page 6 − 74Electrical System

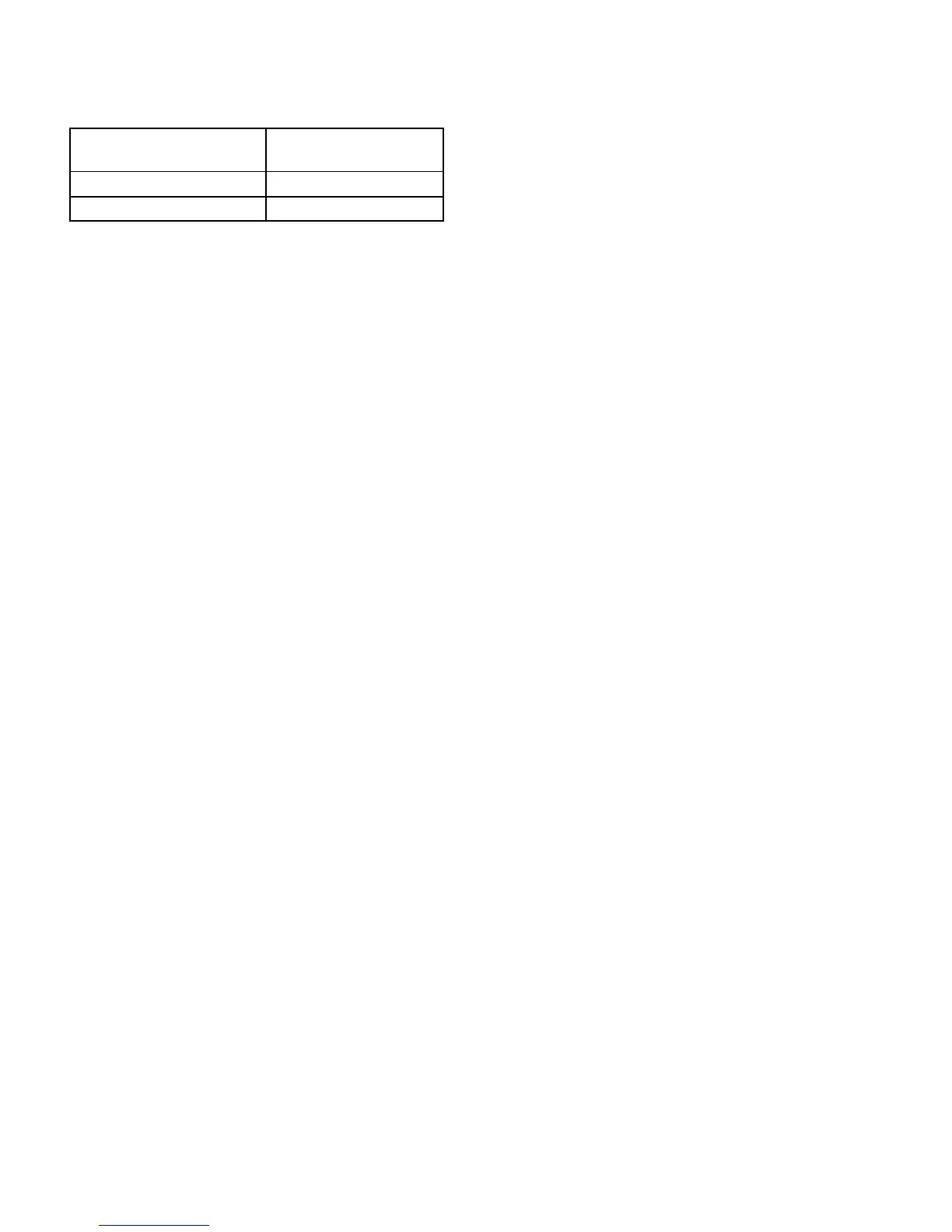

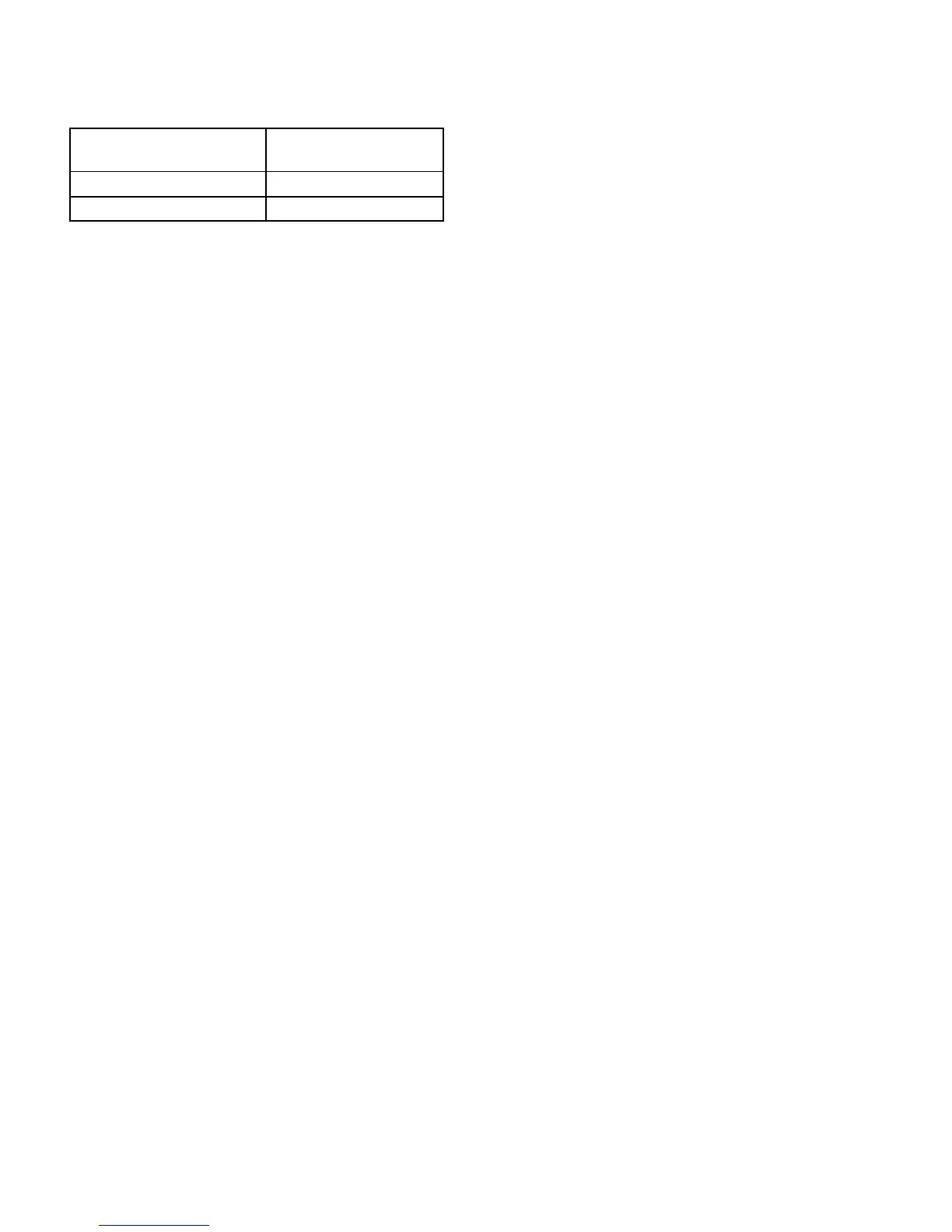

6. Using a multimeter, check resistance across the fuel

sender connector terminals with the float in the full and

empty positions (Fig. 110).

FLOAT ARM

POSITION

RESISTANCE

FULL (UP) 102 ohms

EMPTY (DOWN) 2 ohms

Figure 110

7. Replace fuel sender as necessary.

8. When testing is complete, clean the fuel pick−up

screen and carefully fit gasket and fuel pump/level

sender into fuel tank. Make sure fuel pump/sender float

arm is facing forward as shown (Fig. 108).

9. Secure fuel sender to tank with cap and tighten cap

from 175 to 200 in−lb (20 to 22 N−m). To prevent dam-

age to fuel sender during assembly, make sure that fuel

sender does not turn as sender cap is tightened.

10.Secure wire harness connectors to fuel pump/level

sender.

11.Connect fuel hose to top of fuel tank.

A. Push supply hose barb fitting onto fuel pump/lev-

el sender until an audible “Click” is heard.

B. Press barb fitting lock down to lock fitting in place

(Fig. 109).

12.Prime the fuel system (see Operator’s Manual).

13.Make sure that no fuel leaks exist and install the fuel

tank cover before returning machine to service. Tighten

fuel tank cover screws from 11 to 12 in−lb (1 N−m).

Loading...

Loading...