Multi Pro 5800 Page 6 − 75 Electrical System

Fuel Level Sender (Diesel Engines Only)

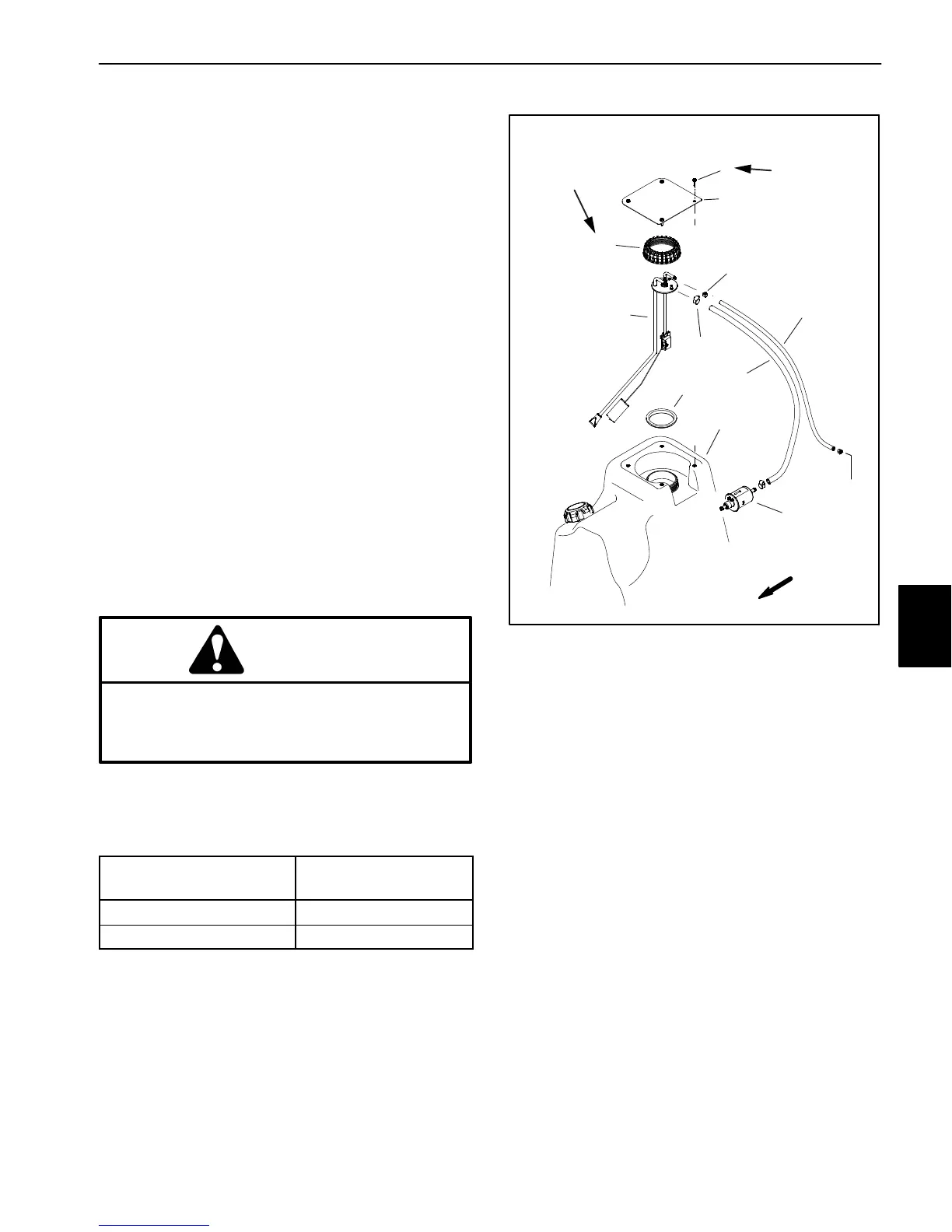

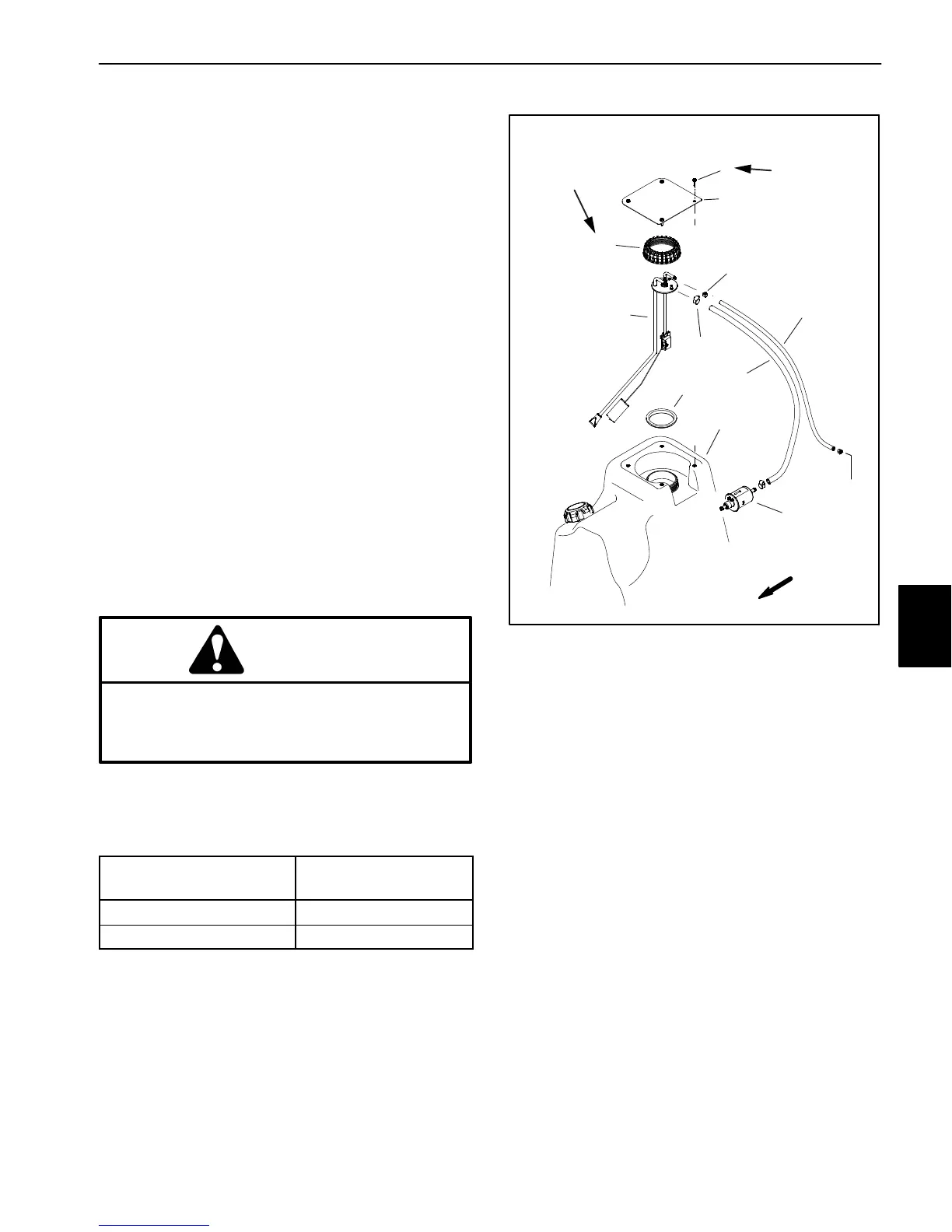

On machines with a diesel engine, the fuel sender is at-

tached to the top of the fuel tank (Fig. 112). The resist-

ance of the fuel sender decreases as the fuel level in the

fuel tank decreases. The fuel sender is connected to a

fuel gauge mounted to the instrument panel.

Testing

1. Park machine on a level surface, stop engine and en-

gage parking brake.

2. Remove fuel tank cover and disconnect machine

wire harness connector from fuel sender.

3. To test the circuit wiring and instrument panel fuel

gauge, turn ignition switch to RUN/PREHEAT. The in-

strument panel fuel gauge should indicate full. Turn igni-

tion switch OFF and proceed with fuel sender testing if

circuit wiring and instrument panel fuel gauge are func-

tioning correctly.

4. Label fuel hoses for assembly purposes then loosen

hose clamps and carefully disconnect fuel supply and

return hoses from fittings on the top of the fuel sender.

5. Remove cap and carefully lift fuel sender and gasket

from fuel tank. Clean all fuel from the sender.

CAUTION

Make sure fuel sender is completely dry (no fuel

on it) before testing. Perform test away from the

fuel tank to prevent an explosion or fire from

sparks.

6. Using a multimeter, check resistance across the fuel

sender connector terminals with the float in the full and

empty positions (Fig. 111).

FLOAT ARM

POSITION

RESISTANCE

FULL (UP) 89 to 95 ohms

EMPTY (DOWN) 5 to 8 ohms

Figure 111

7. Replace fuel sender as necessary.

8. When testing is complete, clean the fuel pick−up

screen and carefully fit gasket and fuel sender into fuel

tank. Make sure fuel sender float arm is facing forward

as shown (Fig. 112).

1. Flange head screw (4)

2. Tank cover

3. Cap

4. Fuel level sender

5. Hose clamp (2)

6. Fuel hose − return

7. Hose clamp (2)

8. Fuel hose − supply

9. Gasket

10. Fuel tank

11. Fuel pump

Figure 112

FRONT

9

4

3

2

1

7

5

6

8

11

FROM

FUEL

RAIL

13 to 65 in−lb

(1 to 7 N−m)

10 to 12 in−lb

(1 N−m)

10

9. Secure fuel sender to tank with cap and tighten cap

from 175 to 200 in−lb (20 to 22 N−m). To prevent dam-

age to fuel sender during assembly, make sure that fuel

sender does not turn as sender cap is tightened.

10.Secure wire harness connector to fuel sender.

11.Connect fuel supply and return hoses to fittings on

the top of the fuel sender and secure hoses with hose

clamps.

12.Bleed fuel system (see Operator’s Manual).

13.Make sure that no fuel leaks exist and install the fuel

tank cover before returning machine to service. Tighten

fuel tank cover screws from 11 to 12 in−lb (1 N−m).

Electrical

System

Loading...

Loading...