Multi Pro 5800 Hydraulic SystemPage 5 − 89

1. Make sure the manifold is clean before removing a

fitting or cartridge valve.

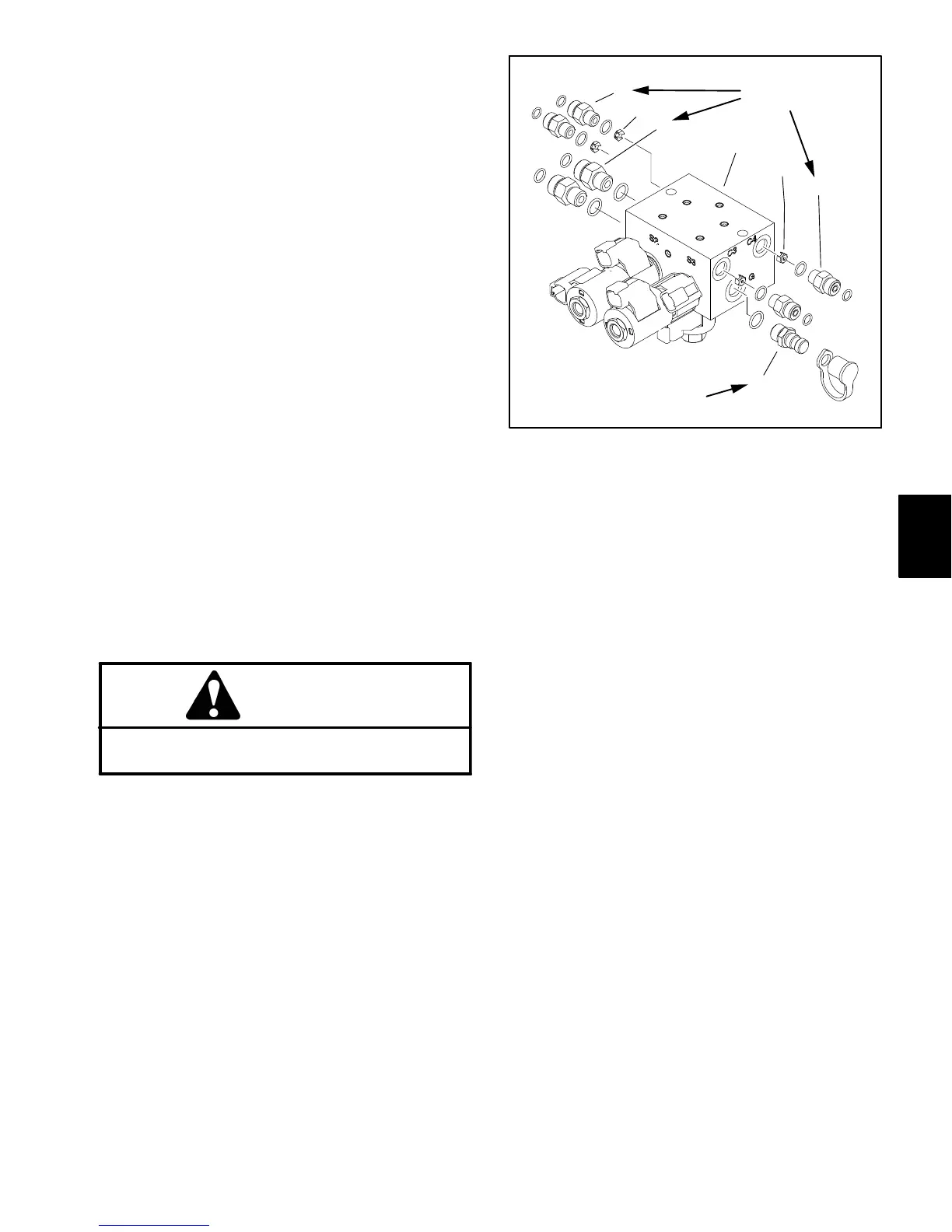

2. If necessary, remove fittings and flow control orifices

from control manifold and discard O−rings (Fig. 65).

3. If cartridge is solenoid operated, remove nut secur-

ing solenoid to the cartridge valve. Carefully slide sole-

noid off the valve.

IMPORTANT: Use care when removing cartridge

valves. Slight bending or distortion of the stem tube

can cause binding and malfunction. Make sure that

deep well socket fully engages the valve base.

4. Remove cartridge valve with a deep well socket.

Note correct location for O−rings, sealing rings and

backup rings on valve. Remove and discard seal kit.

5. Visually inspect the port in the manifold for damage

to the sealing surfaces, damaged threads or contamina-

tion.

6. Visually inspect cartridge valve for damaged sealing

surfaces and contamination.

A. Contamination may cause valves to stick or hang

up. Contamination can become lodged in small valve

orifices or seal areas causing malfunction.

B. If valve sealing surfaces appear pitted or dam-

aged, the hydraulic system may be overheating or

there may be water in the system.

CAUTION

Use eye protection such as goggles when using

compressed air.

7. Clean cartridge valve using clean mineral spirits.

Submerge valve in clean mineral spirits to flush out con-

tamination. Particles as fine as talcum powder can affect

the operation of high pressure hydraulic valves. If car-

tridge design allows, use a wood or plastic probe to push

the internal spool in and out 20 to 30 times to flush out

contamination. Be extremely careful to not damage car-

tridge. Use compressed air for cleaning.

8. Install the cartridge valve:

A. Lubricate new seal kit components with clean hy-

draulic oil and install on valve. The O−rings, sealing

rings and backup rings must be arranged properly on

the cartridge valve for proper operation and sealing.

1. Boom lift manifold

2. Straight fitting (2)

3. Straight fitting (4)

4. Orifice − 0.035 (4)

5. Test fitting

Figure 65

20 to 26 ft−lb

(27 to 35 N−m)

20 to 26 ft−lb

(27 to 35 N−m)

1

2

3

4

3

4

5

IMPORTANT: Use care when installing cartridge

valves. Slight bending or distortion of the stem

tube can cause binding and malfunction. Make

sure that deep well socket fully engages the

valve base.

B. Lubricate threads of cartridge valve with clean

hydraulic oil. Thread cartridge valve carefully into

manifold port. The valve should go in easily without

binding.

C. Torque cartridge valve using a deep well socket

to value identified in manifold illustration.

D. If cartridge is solenoid operated, carefully install

solenoid coil to the cartridge valve. Tighten nut to 60

in−lb (7 N−m). Do not over−tighten nut.

9. If problems still exist, remove valve and clean again

or replace valve.

IMPORTANT: If fitting and flow control orifice were

removed from manifold ports C1, C2, C3 or C4, place

orifice with slot toward the bottom of the port mak-

ing sure that the orifice is flat in the base of the port

before installing fitting. Manifold damage is pos-

sible if the orifice is cocked in the port.

10.If fittings were removed from control manifold, lubri-

cate and place new O−rings onto fittings. Install fittings

into control manifold port openings. Tighten fittings to

specified torque (Fig. 65).

Hydraulic

System

Loading...

Loading...