Multi Pro 5800Hydraulic System Page 5 − 34

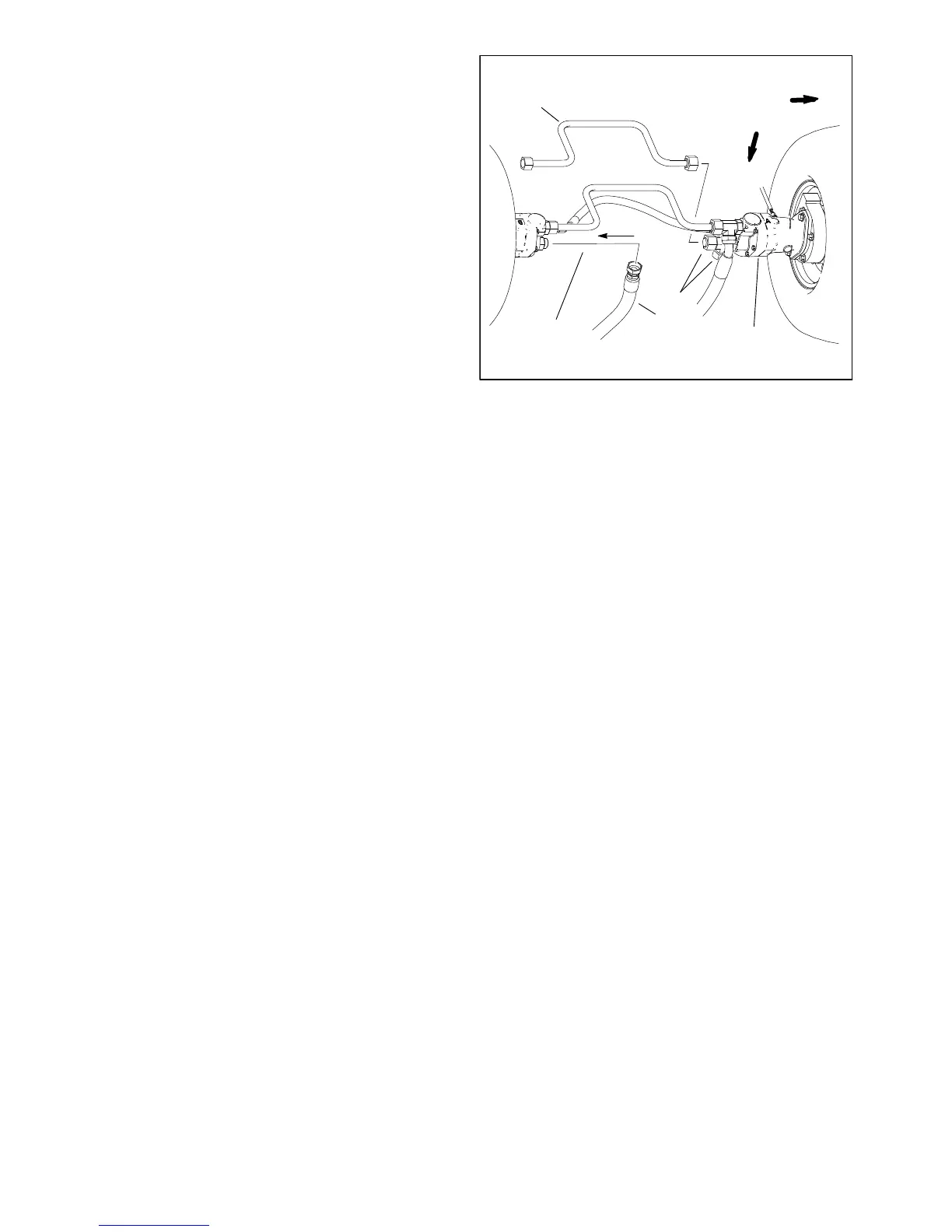

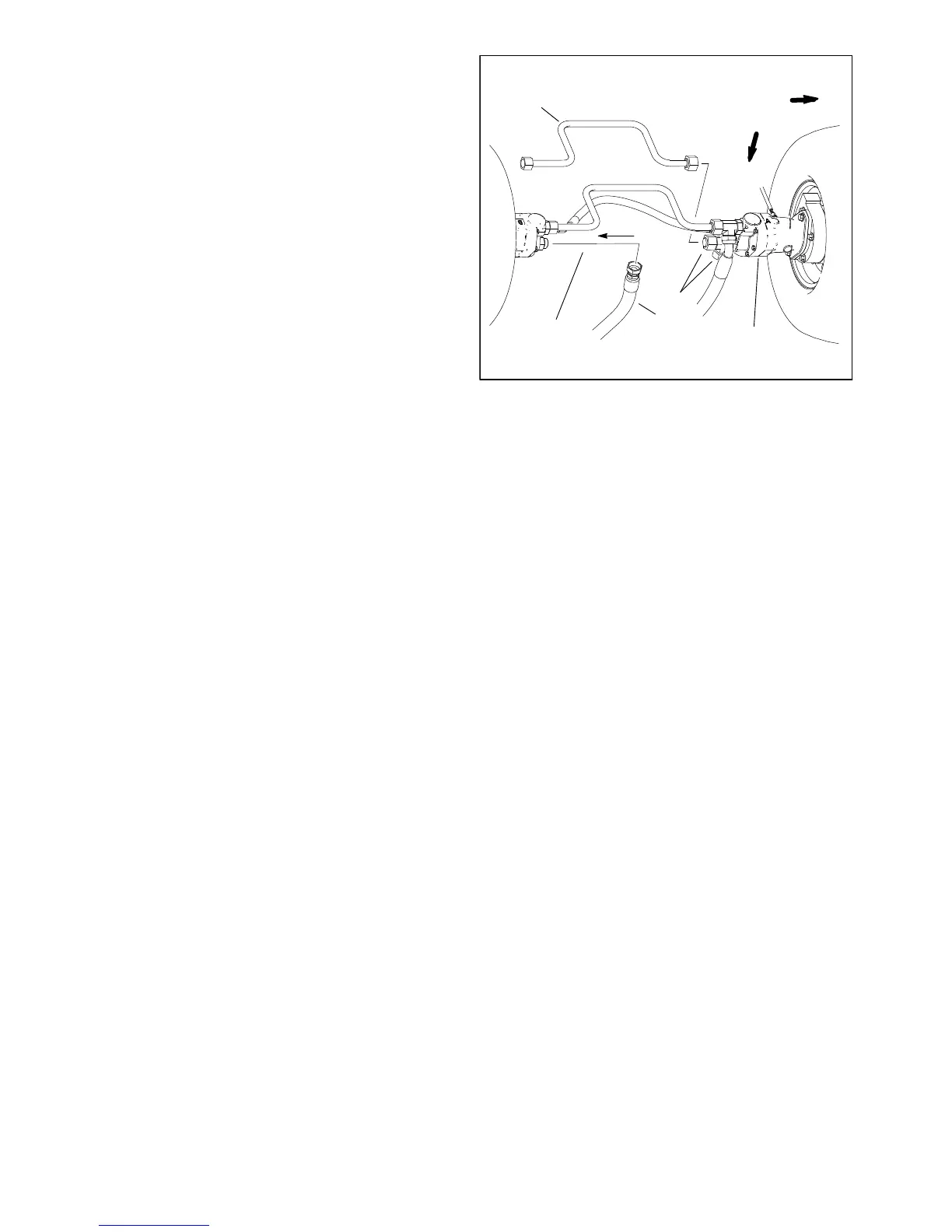

7. To test left side (LH) wheel motor efficiency, isolate

the hydraulic motors and connect a hydraulic tester as

follows (Fig. 28):

A. Thoroughly clean all fittings and hydraulic lines at

both wheel motors.

B. Disconnect both ends of the hydraulic tube

(item 2) and remove it from the machine.

C. Disconnect hydraulic hose from tee fitting at the

“A” port of the RH wheel motor.

D. Cap both openings of the tee fitting at the RH

wheel motor.

IMPORTANT: Make sure that the oil flow indica-

tor arrow on the flow meter is showing that the oil

will flow from the pump (hydraulic hose),

through the tester and into the tee fitting in the

RH wheel motor.

E. Install 15 GPM Hydraulic Tester #TOR214678

(pressure and flow) in series between the fitting at

the “B” port of the LH wheel motor and the discon-

nected hydraulic hose. Use hydraulic hose kit (see

Special Tools in this chapter) if necessary to connect

tester to machine. Make sure that flow control valve

on tester is fully open.

8. Start engine and run at low idle speed. Check for any

hydraulic leakage from tester and hydraulic line connec-

tions. Correct any leaks before proceeding.

9. Increase engine speed to high idle (Diesel Engine:

3050 to 3150 RPM, Gasoline Engine: 3200 RPM)

IMPORTANT: Monitor flow meter carefully during

test. Do not allow system flow to exceed 8 GPM (30

LPM).

10.Have an assistant sit on seat, apply brakes fully and

slowly depress the traction pedal in the forward direction

until 1000 PSI (69 bar) is displayed on the tester pres-

sure gauge.

11.Internal leakage for the wheel motor being tested will

be shown on the flow meter in GPM. Flow should be less

than 2.5 GPM (9.4 LPM) for the wheel motor being test-

ed.

12.If specifications are not met, the wheel motor needs

to be inspected and repaired as necessary (see Wheel

Motors and Wheel Motor Service in this chapter).

1. RH wheel motor

2. Hydraulic tube

3. Cap (2)

4. Hydraulic hose

Figure 28

FRONT

RIGHT

INSTALL

HYDRAULIC

TESTER HERE

1

2

4

3

FLOW

LH WHEEL MOTOR TEST

13.If second wheel motor requires testing, perform test

procedure for the remaining motor.

14.When testing is complete, disconnect tester from

machine. Remove caps, plugs and/or fittings used dur-

ing testing. Connect hydraulic fittings and lines to rear

wheel motor(s).

15.Start engine and run at low idle speed. Check for hy-

draulic leakage and correct before returning machine to

service.

Loading...

Loading...