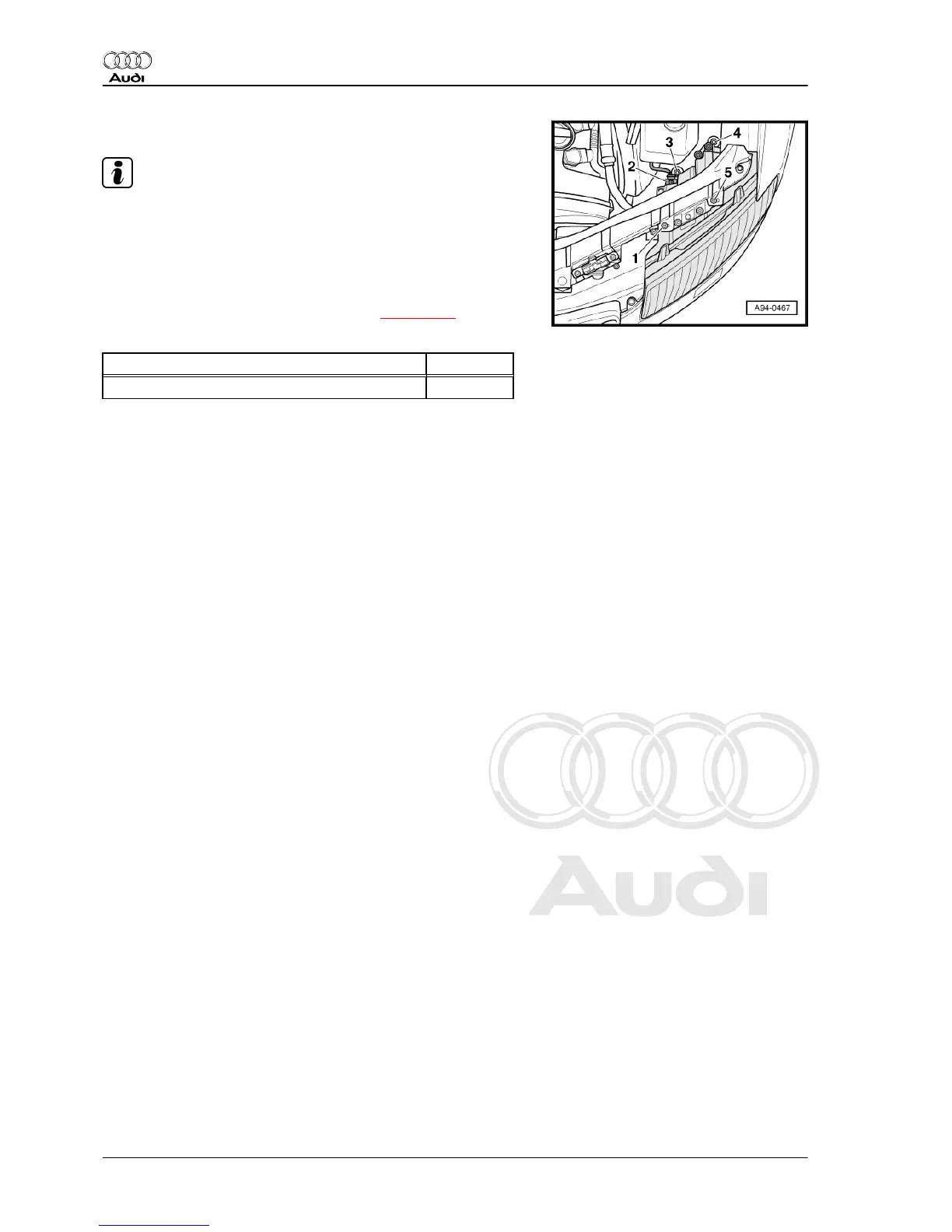

– Tighten bolts -1- and -3 ... 5-.

Note

When the bolt -3- is tightened the adjusting nut of the adjuster

automatically rotates against the mounting point of the headlight

housing and fixes it in place.

– Avoid applying pressure to the bolt when securing; the adjust‐

er nut of the adjuster must remain free to turn.

– Following installation, adjust headlights ⇒ page 140 .

Tightening torque

Component Nm

Headlight to lock carrier 6

3.3 Adjusting headlights

♦ The following checking and adjustment procedures apply to

all countries.

♦ However, national legislation and guidelines for individual

countries must be adhered to.

3.3.1 Requirements for checking and adjust‐

ing

♦ Tyre pressure OK

♦ Headlight lenses must be clean and dry.

♦ Headlight lenses must not be damaged.

♦ Reflectors and bulbs OK

♦ Air reservoir for air suspension full, if necessary start engine

and allow to run at idling speed for approx. 2 minutes then

switch off engine.

♦ Release electromechanical parking brake to relieve any load

on suspension.

♦ Make sure steering wheel is at centre position with wheels

pointing straight ahead.

♦ Vehicle and headlight adjustment unit must be on a level sur‐

face.

♦ Headlight adjustment unit must be aligned to vehicle ⇒ Op‐

erating instructions for headlight adjustment unit .

Ensure that headlight adjustment unit is in front of headlight at a

distance of 30 cm.

♦ Dip setting must be adjusted.

Dip settings (in “%”) are marked on the top of the headlight. The

headlights must be adjusted in accordance with these values. The

percentage value is for a range of 10 m. Example: Converting a

dip setting of 1.0 % = 10 cm.

3.3.2 Checking headlight settings

– Start engine.

– Switch on dipped headlights.

– Set vehicle level to normal.

Audi A8 2003 ➤

Electrical system - Edition 08.2014

140 Rep. gr.94 - Lights, bulbs, switches - exterior

Loading...

Loading...