892-0000010B OM

77

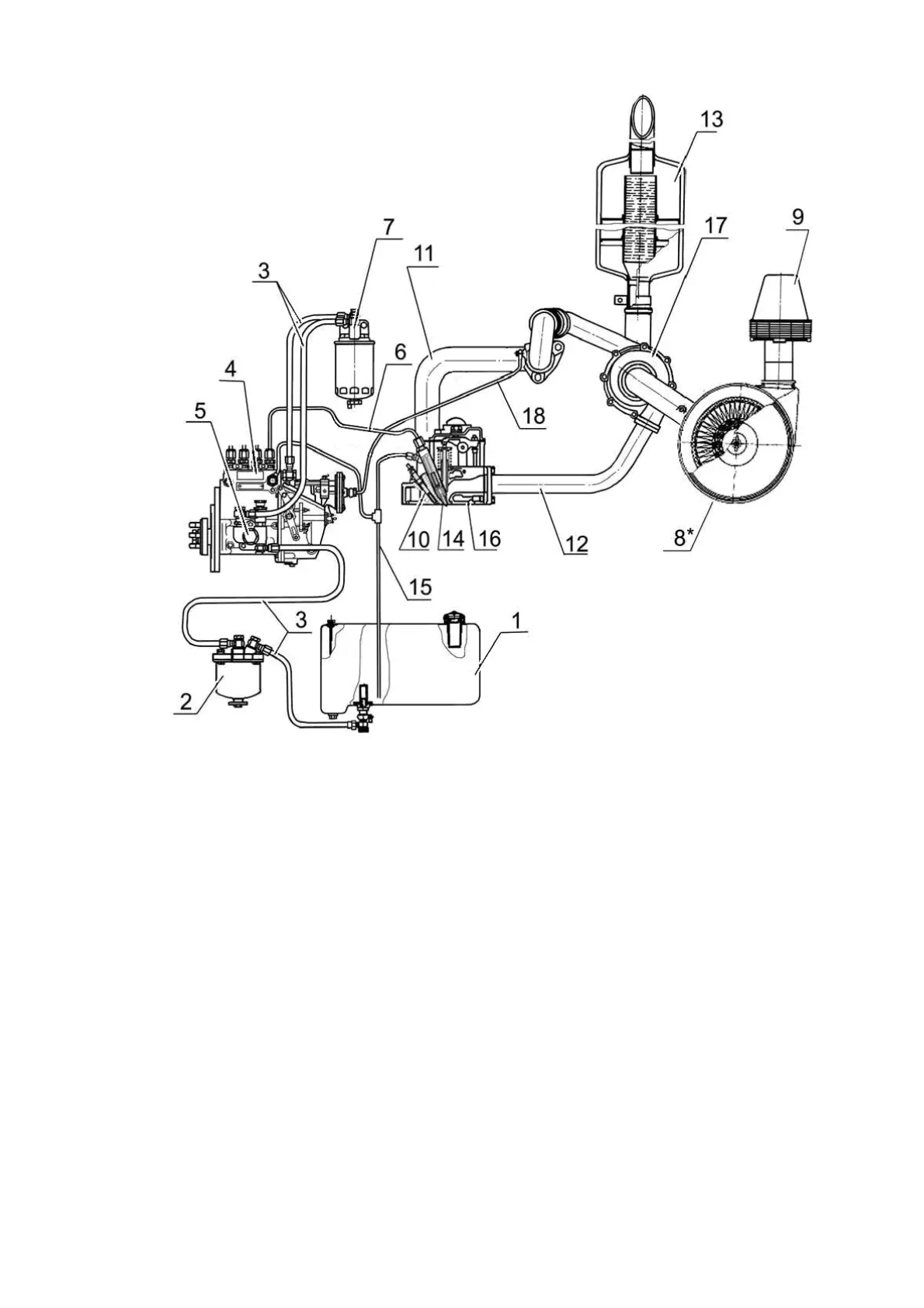

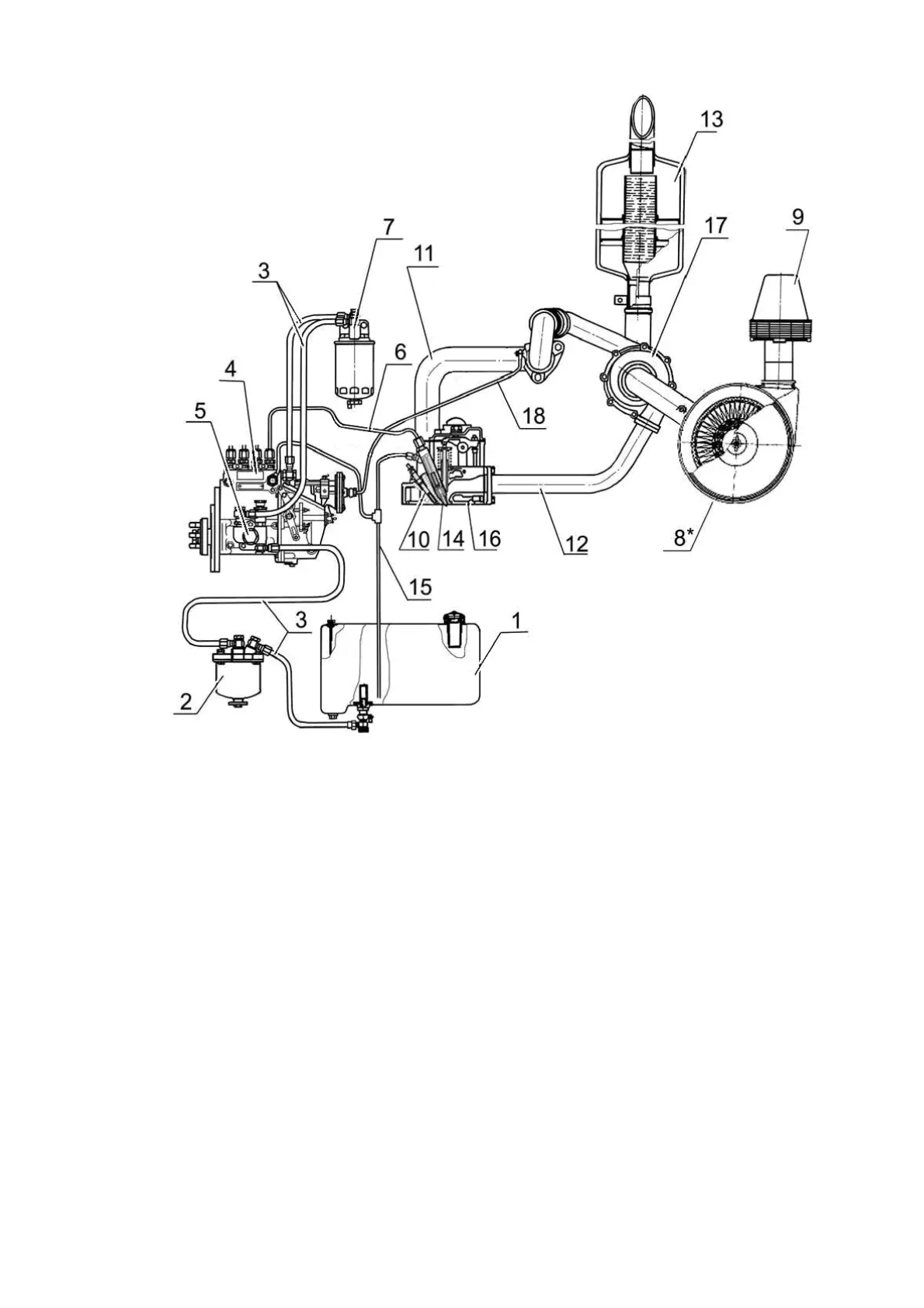

1 - fuel tank; 2 - coarse fuel filter; 3 - low pressure fuel pipes; 4 - high pressure fuel pump; 5

- fuel priming pump; 6 - high pressure fuel line; 7 – fuel fine filter; 8 - air cleaner; 9 - mono-

cyclone; 10 - glow plug; 11 - intake manifold; 12 - exhaust manifold; 13 - muffler; 14 - injector;

15 - fuel outlet pipe to the tank; 16 - cylinder head; 17 - turbocharger; 18 - pneumatic cor-

rector tube.

Figure 3.1.2 – Diagram of fuel supply system of D-245.5 engine.

Injector 14 (Figure 3.1.2) is designed to inject fuel into the engine cylinder. It provides

the necessary fuel atomization and limits the start and end of the feed.

Coarse filter 2 is used for preliminary fuel purification from mechanical impurities and

water. The coarse filter consists of a body, a reflector with a grid, a diffuser, a cup with a

dampener. Sludge is drained from the filter through a hole in the bottom of the cup, closed

with a stopper.

Fine filter 7 serves for the final purification of fuel. The fine filter has a replaceable

paper element. Fuel, passing through the curtains of the paper filter element, is cleaned of

mechanical impurities. In the lower part of the filter housing there is a hole with a plug for

draining the sludge. To remove air from the fuel supply system, a special plug is located on

the filter cover.

Air cleaner 8 is used to clean the air sucked into the cylinders. Detailed information

about the structure and operation of the intake duct of the BELARUS-892/892.2 tractors is

presented in subsection 3.1.2 "Engine air cleaning system".

Engine cooling is liquid with forced circulation of coolant from a centrifugal pump.

The temperature of the coolant in the system is controlled by the temperature gauge on the

instrument panel. The temperature gauge sensor is installed in the cylinder head. A place is

provided for installing the sensor in the thermostat housing. Do not operate the engine when

Loading...

Loading...