F 71 8

A

If a different pressure is detected during the measurement process, proceed as fol-

lows:

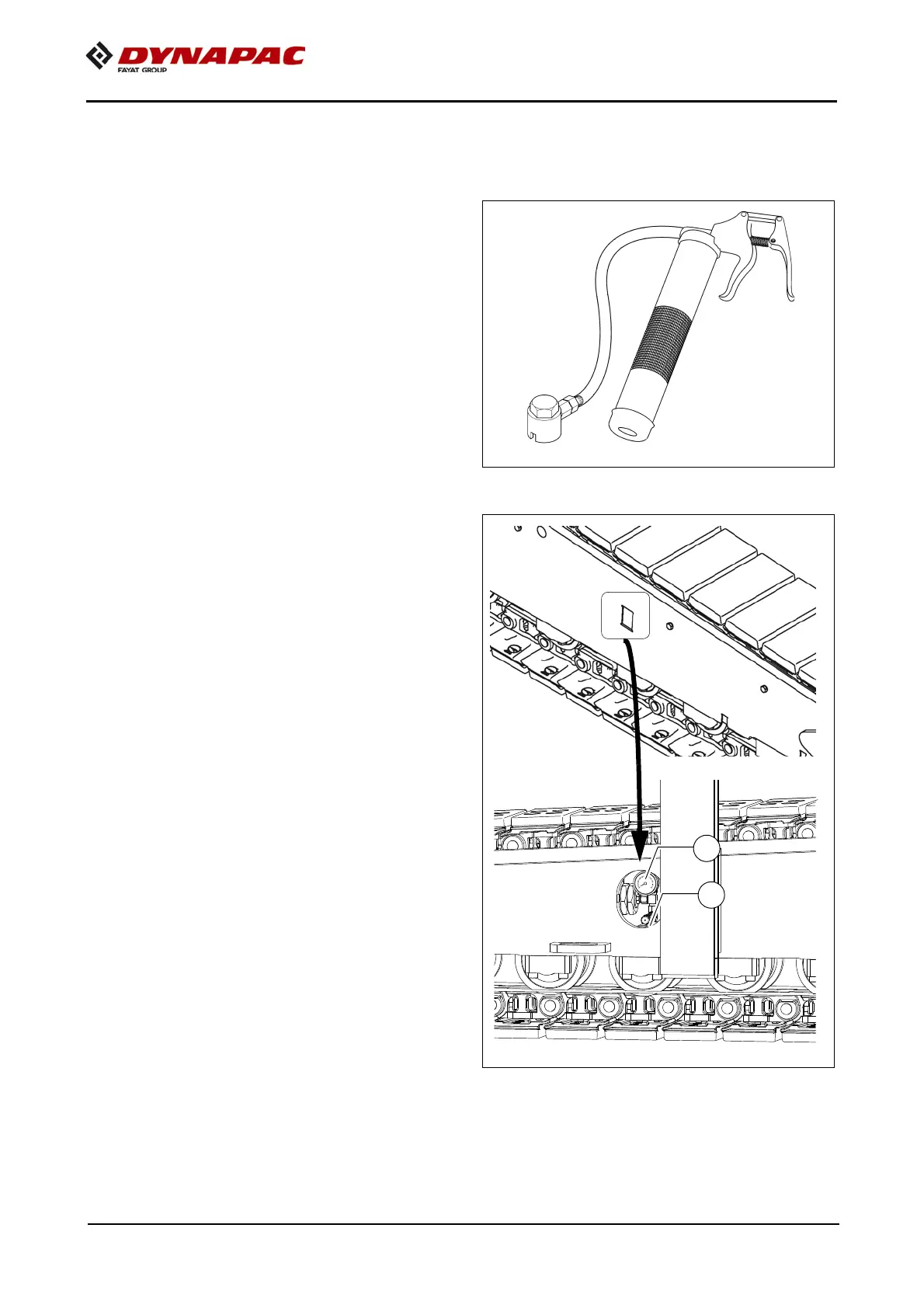

- Screw head section for flat nipple

(toolbox) onto the grease gun.

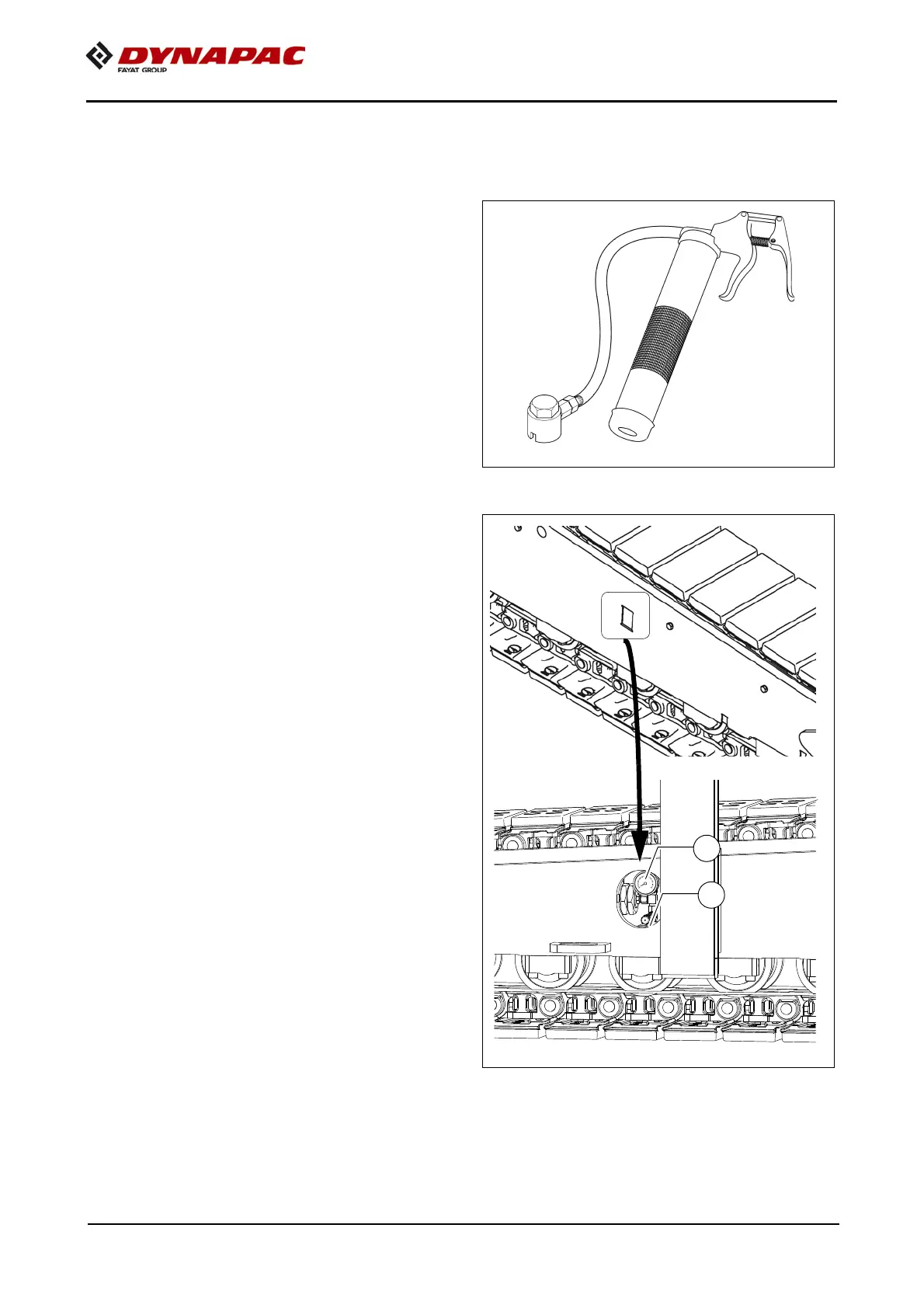

- Top up the grease in the chain tighten-

er at the filling connection (A) until the

correct pressure appears at the pres-

sure gauge (B).

- Remove the grease gun again.

A

If the tension is too high: see section

"Relieving the chain".

A

Repeat this procedure on both

drive units!

Relieving the chain:

f

The grease in the tensioning element is

under pressure. Carefully and slowly un-

screw the filling valve, but not too far.

- Unscrew the filling connection (A) us-

ing a tool until the grease is able to

emerge from the lateral hole.

A

The idler wheel moves back independ-

ently or must be reset manually.

- Close the filling connection again

properly as soon as the correct

pressure appears at the pressure

gauge (B).

Loading...

Loading...