3. Operation of CON Related Controllers

34

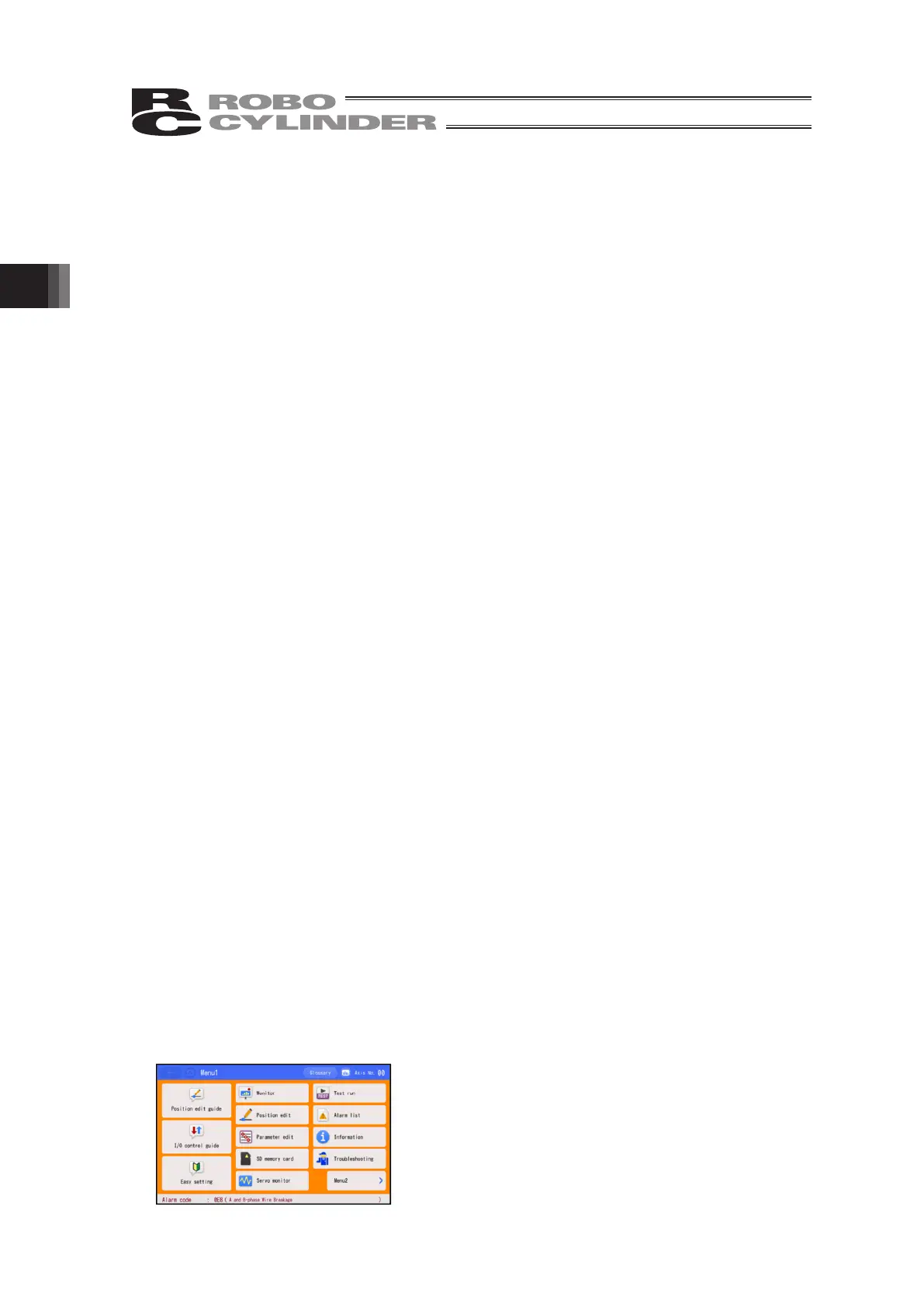

Position edit Conduct setting for position, velocity and acceleration /

deceleration in order to operate an actuator. [Refer to 3.10

Position Edit]

Pressing program edit It should be displayed when a servo pressing type controller

(such as SCON-CB-F) is connected. [Refer to 3.26 Pressing

Program Edit]

Parameter edit Conduct parameter tunings to adjust system, to use additional

features and so on. [Refer to 3.11 Parameter Edit]

SD memory card Conduct readout of each type of data such as position data,

parameters and alarm list and save them, and update software

of TB-02. [Refer to 3.19 Data Backup]

Servo monitor The actual operation status of the actuator is displayed in a

waveform. It is available to record the displayed data. [Refer to

3.25 Servo Monitor]

Test run

Conduct manual operation with JOG, Inching and number indication

and also make a trial run of I/O. [Refer to 3.12 Trial Run]

Alarm list Shows a list of alarms and the time when they occurred. [Refer

to 3.14 Alarm List]

Information Shows the software version, network information, manufacturing

information, maintenance information and models available for

connection. [Refer to 3.17 Information Display]

Troubleshooting Shows the contents of an alarm and the countermeasure when

an alarm has been generated.

Menu 2 list

Change operation axis Select an axis to operate when multiple units of controllers are

connected to the communication line. [Refer to 3.4 Operation

Axis Change]

TP op. mode Switch over between forbidden and permitted for PIO operation

and between invalid and valid for the safety velocity. [Refer to

3.13 TP Operation Mode]

Env. set. Conduct settings for display language, touch sound, turn-off

time, data input warning, axis name display, password, display,

clock and initial window setting at startup. [Refer to 3.18

Environment Setting]

Controller reset Restart the controller. [Refer to 3.15, Restarting Controller.]

Other setting Conduct parameter initializing and axis number, loadcell

calibration, loadcell invalidation, I/O customizing change. [Refer

to 3.16 Other Settings]

Maintenance parts list Displays information of maintenance parts. [Refer to 3.21

Maintenance Part List]

Easy programming It is a window that enables setting of movement between

positions, timer and repeated operation by indicating number,

and to have continuous operation manually. [Refer to 3.22

Simple Program]

Offboard tuning Setting of optimum controlling parameters, each types of gain

and calculation of cycle time are performed. [Refer to 3.24

Offboard tuning]

Pulse train mode setting Conduct the settings to have the pulse train control. [Refer to

3.23 Pulse Train Control Mode Setting]

When an alarm generates, the corresponding alarm code and

message will appear at the bottom of the screen and the

background color will change to orange.

Loading...

Loading...