3. Operation of CON Related Controllers

68

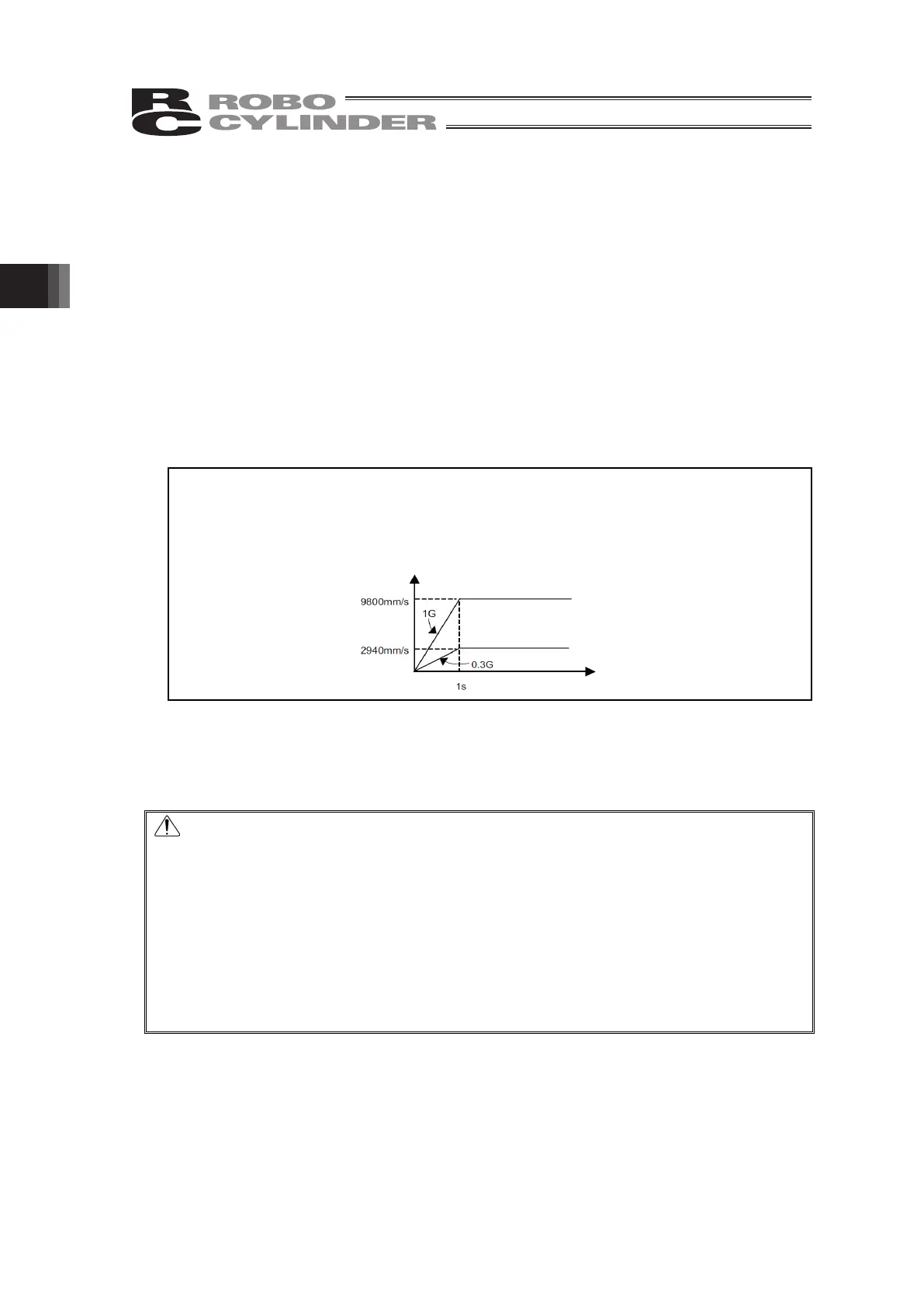

Speed

Time

(Reference) Acceleration is explained. The same concept applies to deceleration.

1 G = 9800 mm/s

2

: Acceleration at which the actuator can increase its speed up to 9800

mm/s per second.

0.3 G: Acceleration at which the actuator can increase its speed up to 2940 mm/s (9800

mm/s × 0.3) per second.

(3) Speed [mm/sec]

Enter the speed at which to move the actuator.

The default value varies depending on the actuator type.

(Note) For SCON-CA/CAL/CB, PCON-CA/CFA/CB/CFB/CYB, ACON-CA/CB/CYB,

DCON-CA/CB/CYB, ERC3, RCP6S, MCON and MSCON, an alarm will be displayed if

the set value is lower than the minimum velocity.

(4) Acceleration/deceleration [G]

Enter the acceleration/deceleration at which to move the actuator.

Basically you should set acceleration/deceleration not exceeding the rated value shown in the

catalog.

The input range permits entry of values larger than the rated value shown in the catalog, but

this is because "shorter tact time when the transferring mass is significantly lighter than the

rated value" is assumed.

If the load vibrates during acceleration/deceleration to present problems, decrease the value set

here.

(Note) For SCON-CA/CAL/CB, PCON-CA/CFA/CB/CFB/CYB, ACON-CA/CB/CYB,

DCON-CA/CB/CYB, ERC3, RCP6S, MCON and MSCON, an alarm will be displayed if

the set value exceeds the rated acceleration/deceleration.

Caution: Acceleration/deceleration setting

(1) Set accelerations/decelerations not exceeding the rated acceleration/deceleration specified in

the catalog or in the instruction manual of the actuator. If any acceleration/deceleration is set

that exceeds the rated acceleration/deceleration, the life of the actuator may be significantly

reduced.

(2) If the actuator or work part receives impact or generates vibration, lower the

acceleration/deceleration. If the system is used continuously with the actuator or work part

receiving impact or generating vibration, the life of the actuator may be significantly reduced.

(3) If the load transferred by the actuator is significantly lighter than the rated payload capacity, you

may be able to set accelerations/decelerations exceeding the rating. If this is the case, the tact

time can be reduced, so contact IAI. When contacting IAI, tell us the weight, shape and

installation method of your work part and installation condition (horizontal/vertical) of your

actuator.

(5) Push [%]

Select “Positioning operation” or “Push-motion operation.”

The factory setting is 0.

0 : Positioning operation is performed.

Other than 0 : Push-motion operation with the entered value as the current-limiting value is

performed.

Loading...

Loading...