4-32 Operation

4.10.7.2 Dot Parameters

You can control the size and accuracy of dot dispensing by setting dot parameters. You may define up to

ten different dot styles. The dot style is selected when entering a dot dispensing instruction into your

program.

Dot parameters are divided into three categories according to when each parameter is implemented during

the dispensing process. Parameters include items such as settling time, dispense gap, valve-on time, and

retract distance.

To edit dot parameters:

1. In the Programming Window, click on

Edit > Edit Dot Parameters from the menu bar.

A window may open indicating the type of valve installed on your dispensing system

and which valve, Valve 1 or Valve 2, is currently active.

2. Click on

OK.

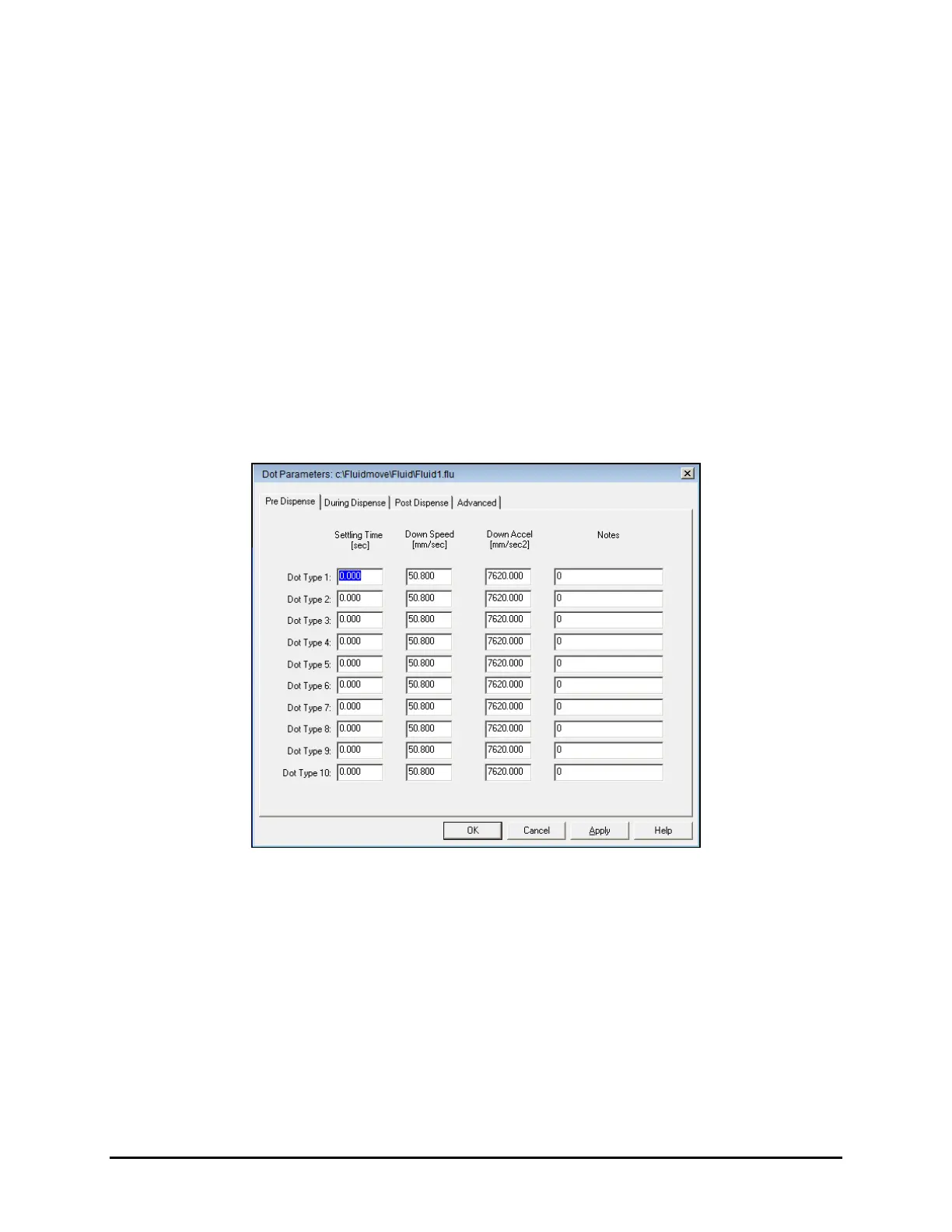

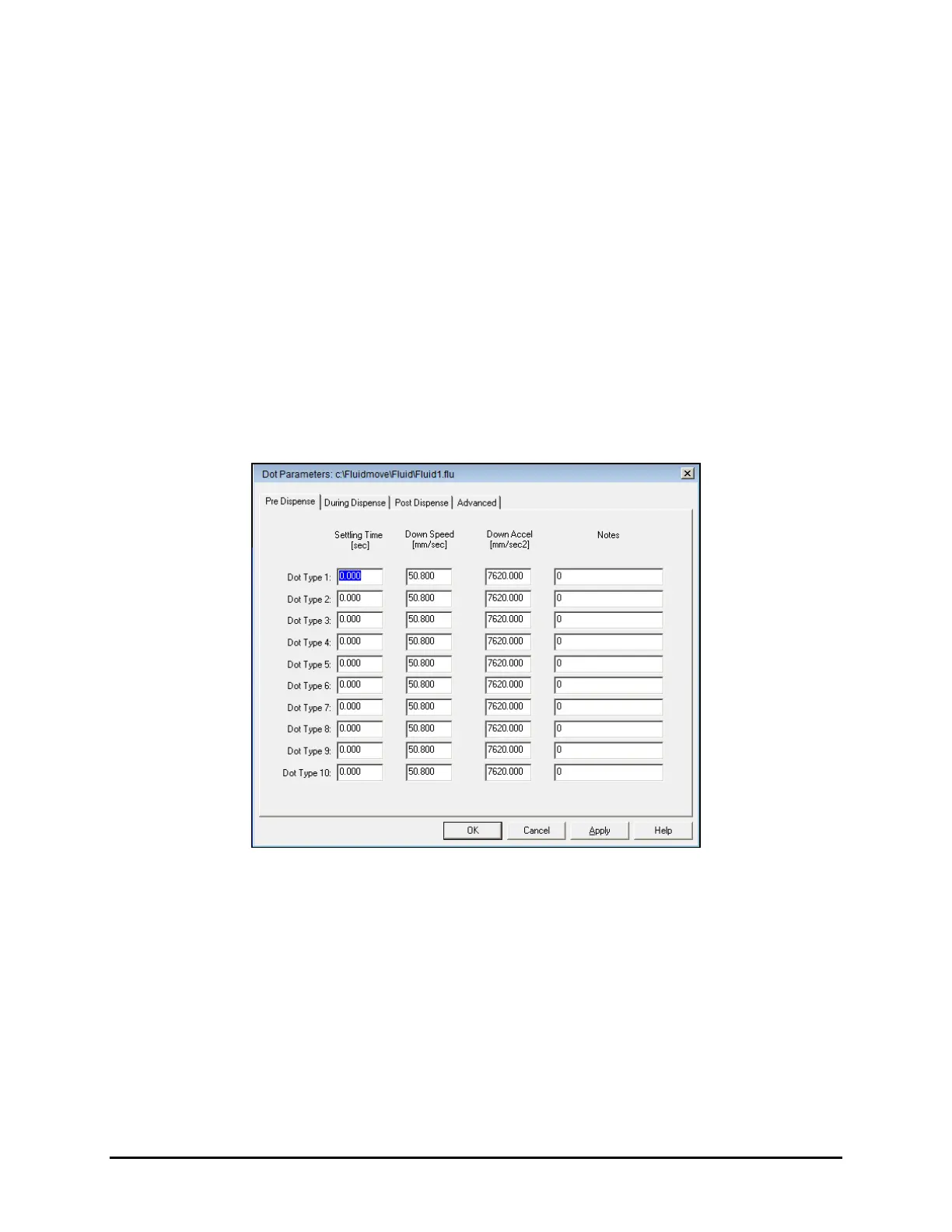

The Dot Parameters window opens (Figure 4-27).

Refer to the Fluidmove User Guide or Online Help for a description of the options.

Figure 4-27 Dot Parameters

3. Click on the desired tab and enter the new value in the appropriate text box.

4. Click

OK when done.

The Dot Parameters window will close.

5. Dot parameters are saved in the fluid file. Select

File > Fluid Table > Save in the

Programming Window to save the dot parameters.

NOTE When you edit dot parameters, it affects all dots in the program associated with that style.

If you just want to change parameters for one dot in a program, you should define a

new style.

Loading...

Loading...