7

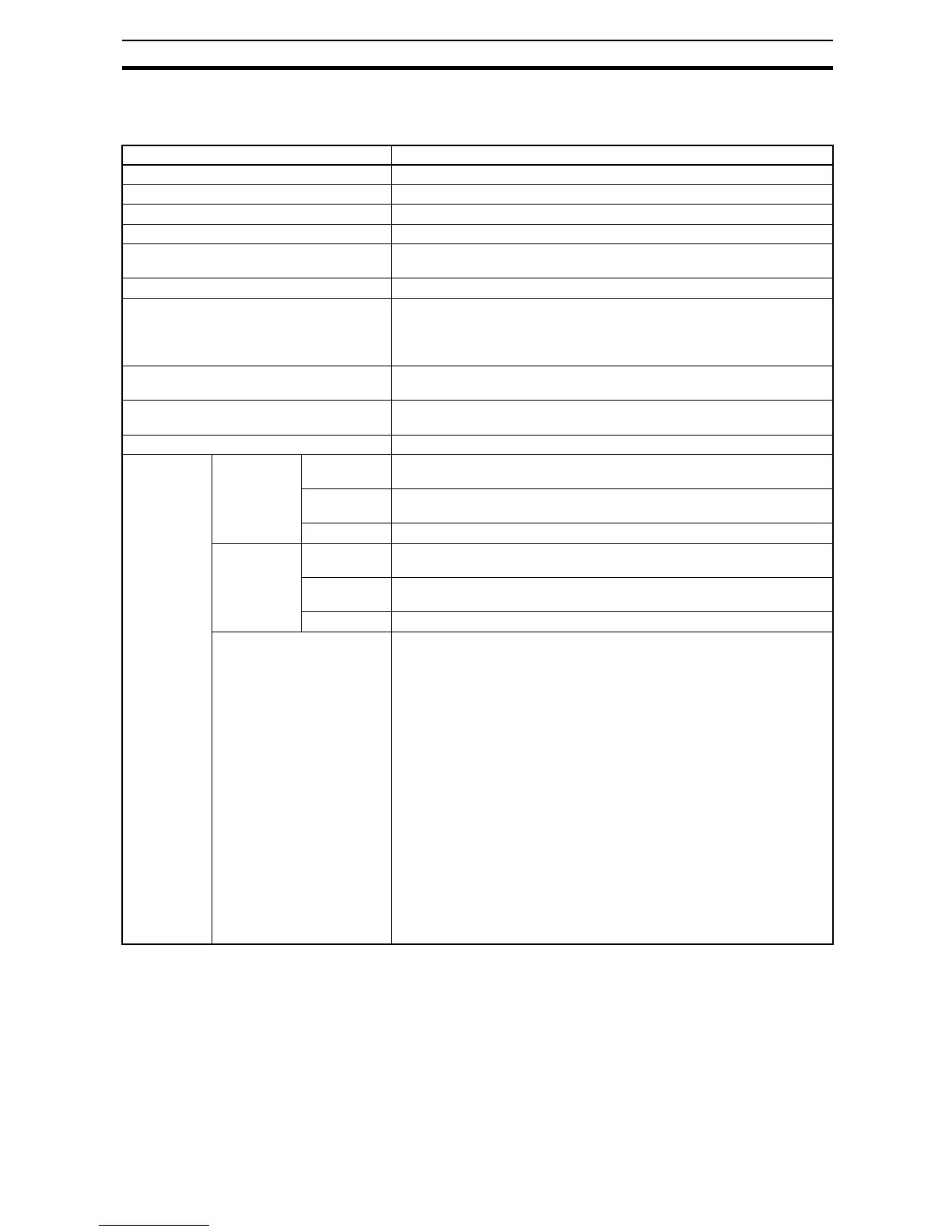

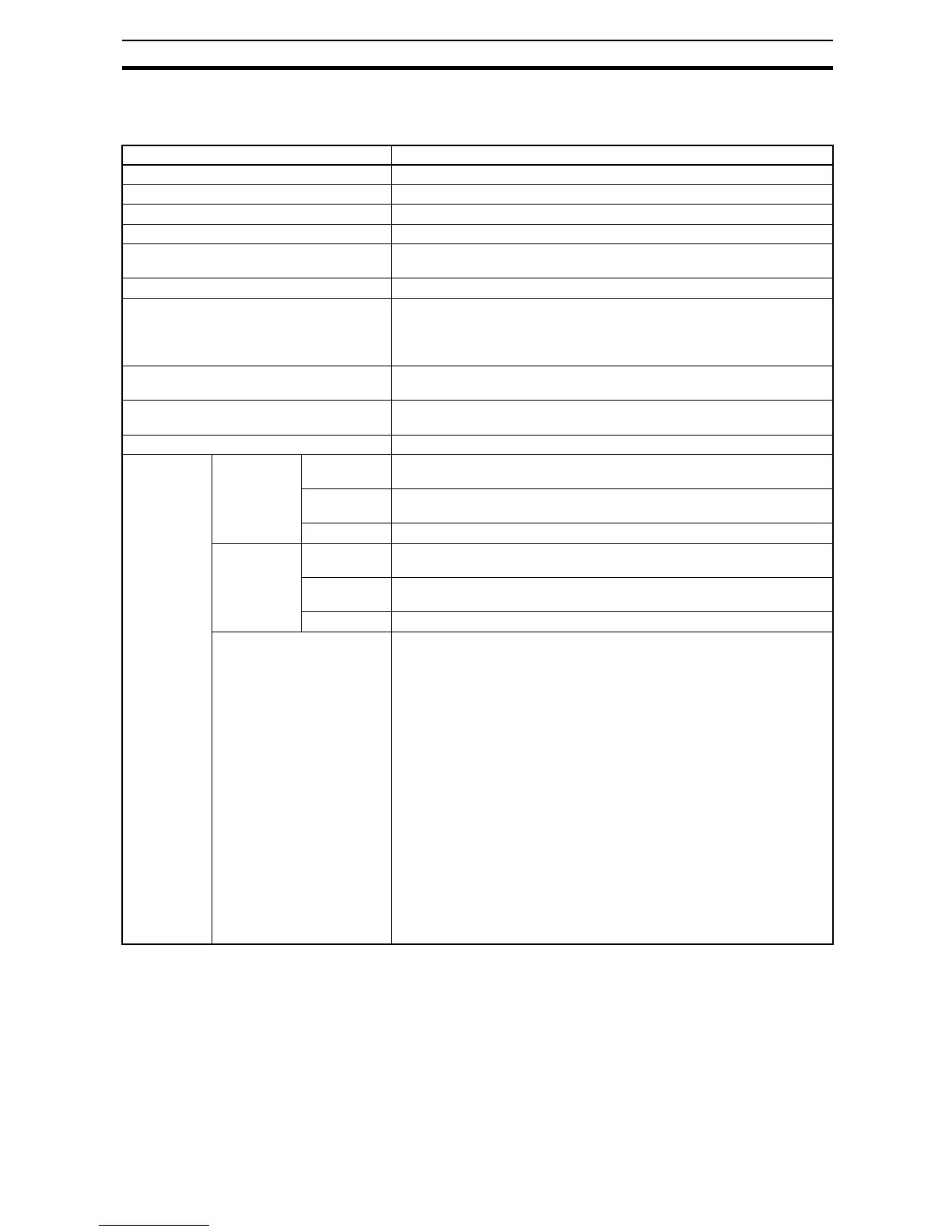

MX2 Inverter Specifications Section 1-2

1-2-2 General Specifications

The following table applies to all MX2 inverters.

Item General Specifications

Protective housing IP 20

Control method Sinusoidal Pulse Width Modulation (PWM) control

Carrier frequency 2 kHz to 15 kHz (derating required depending on the model)

Output frequency range *4 0.1 to 1000 Hz

Frequency accuracy Digital command: 0.01% of the maximum frequency

Analog command: 0.2% of the maximum frequency (25°C ±10°C)

Frequency setting resolution Digital: 0.01 Hz; Analog: max. frequency/1000

Volt./Freq. characteristic V/f control (constant torque, reduced torque, free-V/F): base freq. 30 Hz

~1000 Hz ad-justable

Sensorless vector control, Closed loop control with motor encoder feed-

back: base freq. 30 Hz ~ 400 Hz ad-justable

Overload capacity Dual rating: CT(Heavy duty) : 60 sec. @150%

VT(Normal duty) : 60 sec. @120%

Acceleration/deceleration time 0.01 to 3600 seconds, linear and S-curve accel/decel,

second accel/decel setting available

Starting torque 200% @0.5 Hz (sensorless vector control)

Input signal Freq. setting Operator

panel

Up and Down keys / Value settings

External

signal *8

0 to 10 VDC (input impedance 10 k Ohms), 4 to 20 mA (input impedance

100 Ohms), Potentiometer (1 k to 2 k Ohms, 2 W)

Via network RS485 ModBus RTU, other network option

FWD/REV

run

Operator

panel

Run/Stop (Forward/Reverse run change by command)

External

signal

Forward run/stop, Reverse run/stop

Via network RS485 ModBus RTU, other network option

Intelligent input terminal

Seven terminals, sink/source

changeable by a short bar

68 functions assignable

FW (forward run command), RV (reverse run command), CF1~CF4 (multi-

stage speed setting), JG (jog command), DB (external braking), SET (set

second motor), 2CH (2-stage accel./decel. command), FRS (free run stop

command), EXT (external trip), USP (startup function), CS (commercial

power switchover), SFT (soft lock), AT (analog input selection), RS (reset),

PTC (thermistor thermal protection), STA (start), STP (stop), F/R (forward/

reverse), PID (PID disable), PIDC (PID reset), UP (remote control up func-

tion), DWN (remote control down function), UDC (remote control data

clear), OPE (operator control), SF1~SF7 (multi-stage speed setting; bit

operation), OLR (overload restriction), TL (torque limit enable), TRQ1

(torque limit changeover1), TRQ2 (torque limit changeover2), BOK (Brak-

ing confirmation), LAC (LAD cancellation), PCLR (position deviation clear),

ADD (add frequency enable), F-TM (force terminal mode), ATR (permis-

sion of torque command input), KHC (Cumulative power clear), MI1~MI7

(general purpose inputs for EzSQ), AHD (analog command hold),

CP1~CP3 (multistage-position switches), ORL (limit signal of zero-return),

ORC (trigger signal of zero-return), SPD (speed/position changeover),

GS1,GS2 (STO inputs, safety related signals), 485 (Starting communica-

tion signal), PRG (executing EzSQ program), HLD (retain output frequen-

cy), ROK (permission of run command), EB (rotation direction detection of

B-phase), DISP (display limitation), NO (no function)

Loading...

Loading...